Self anti-scale corrosion-resisting electrical heated tube

An electric heating tube and corrosion-resistant technology, applied in the direction of the heating element shape, immersion heating device, etc., can solve the problems of affecting the heating speed, complex structure, and affecting the safety performance of the whole machine, so as to improve the safety performance and service life, improve the resistance Corrosion ability, the effect of solving surface scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A kind of embodiment of the patent of the present invention is described in detail below according to accompanying drawing.

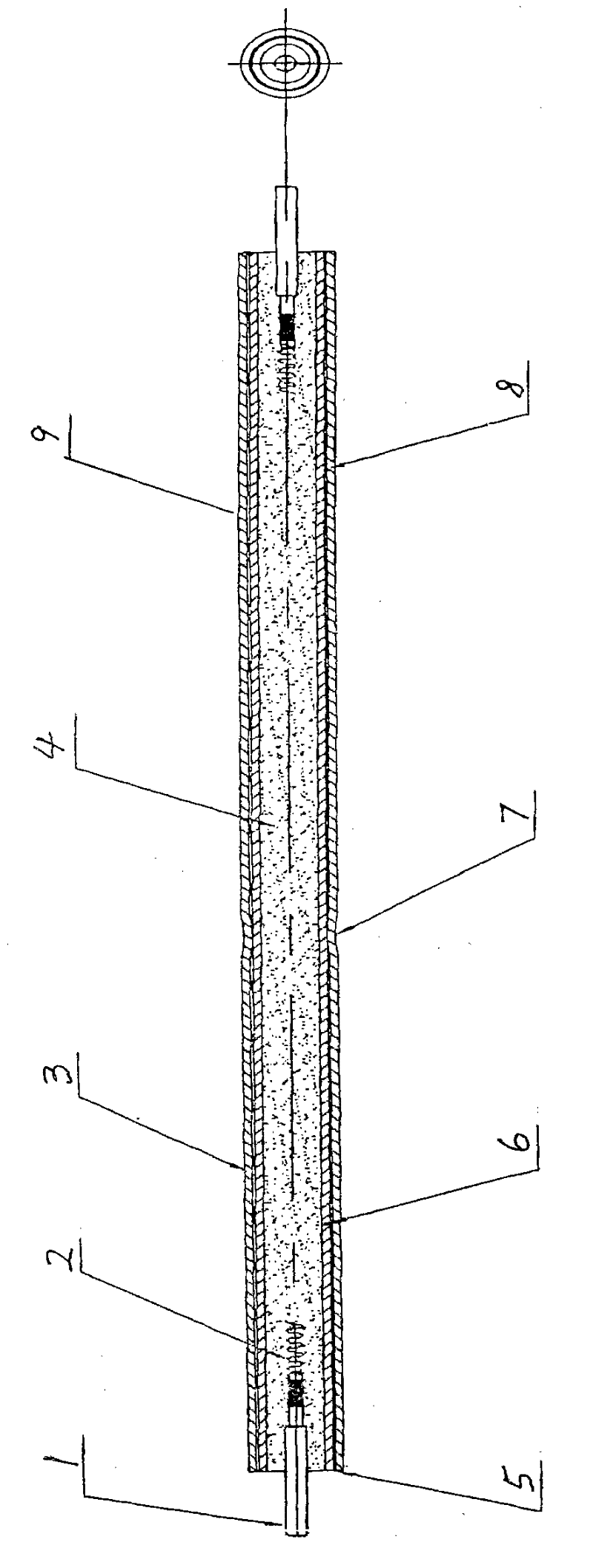

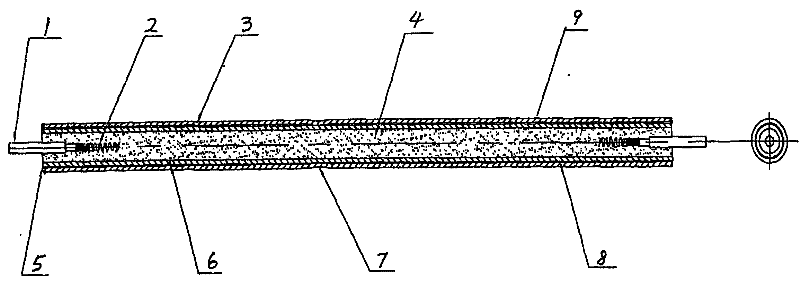

[0009] as attached figure 1 As shown, the present invention includes that the lead rod is a lead rod (1), a heating wire (2), an outer metal sleeve (3), an inner metal sleeve (6), and high temperature resistant magnesium oxide powder (4). The electric heating tube (9) is made up of an outer metal pipe sleeve (2) and an inner metal pipe sleeve (6) made of two different metal materials, and an outer metal pipe sleeve (3) and an inner metal pipe sleeve (6) are provided An air layer (8), in the middle section of the electric heating tube (9), there is an outer metal sleeve (3) and an inner metal sleeve (6) at the merging point (7). Each end has a high-frequency welding point (5) to connect the outer metal sleeve (3) and the inner metal sleeve (6), and the inner metal sleeve (6) is built with high temperature resistant magnesium oxide powder (4). (9...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap