Tower plate bearing structure of large-scale cross-flow plate type tower

A support structure and cross-flow plate technology, applied in the field of plate towers, can solve the problems of low efficiency, space utilization, and mass transfer area of cross-flow plate towers, so as to reduce stagnation area and liquid back-mixing, improve The efficiency of the whole tower and the effect of uniform liquid flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

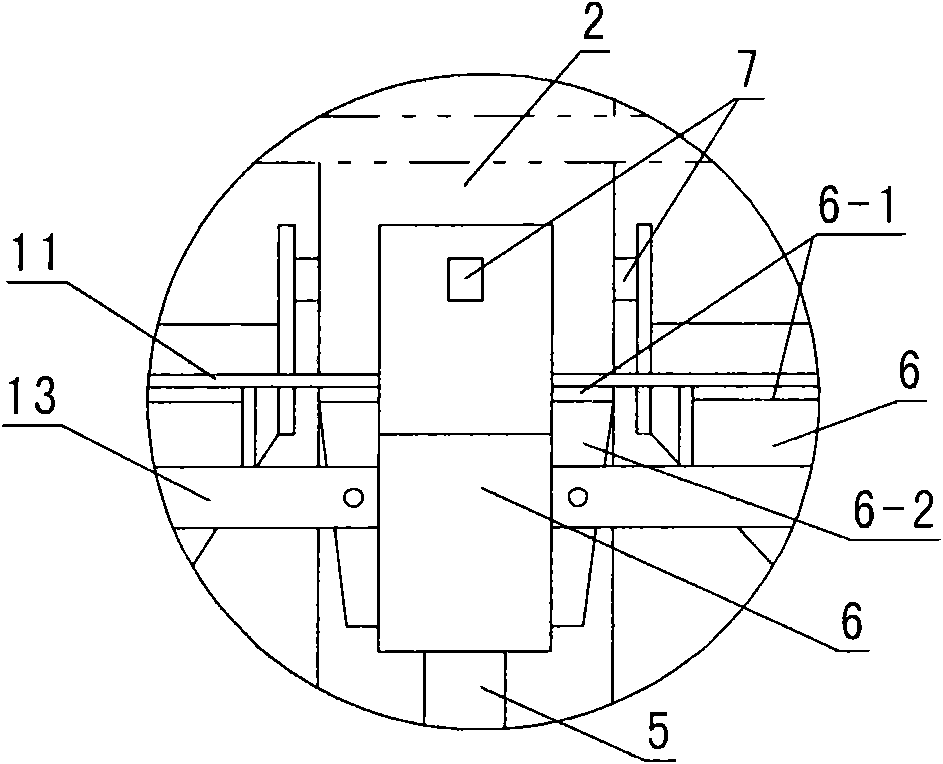

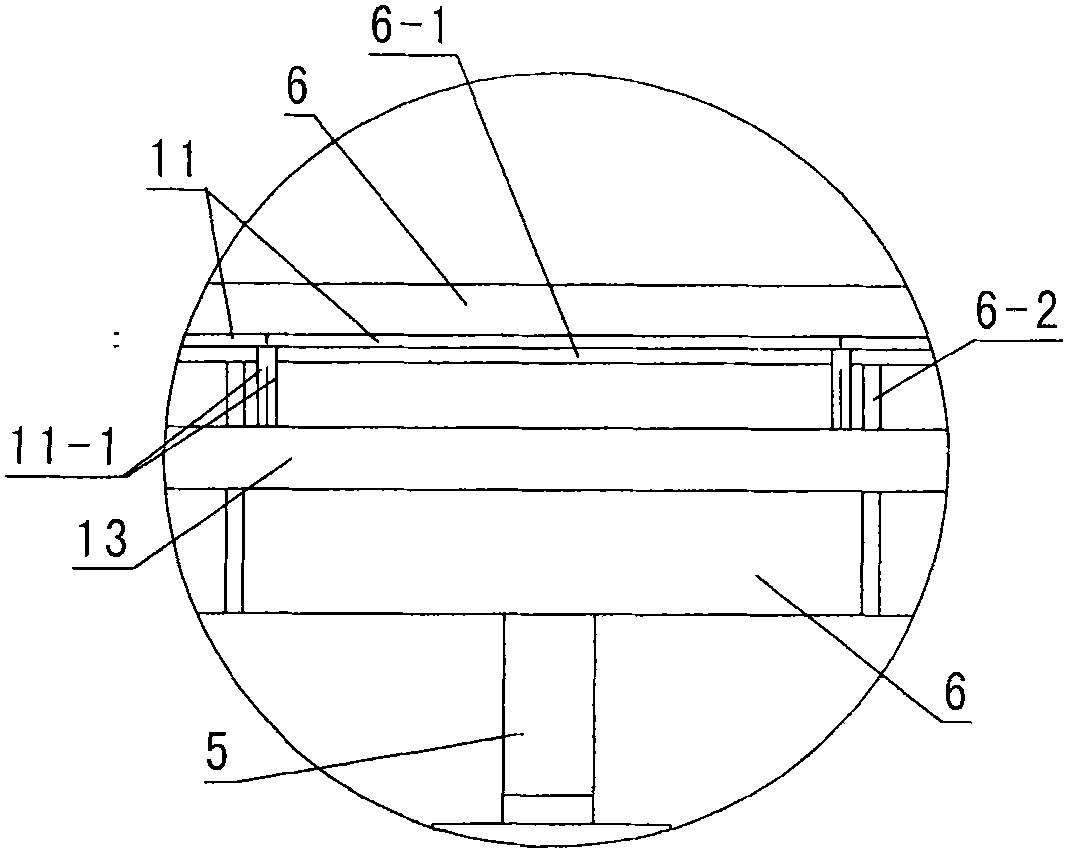

[0018] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

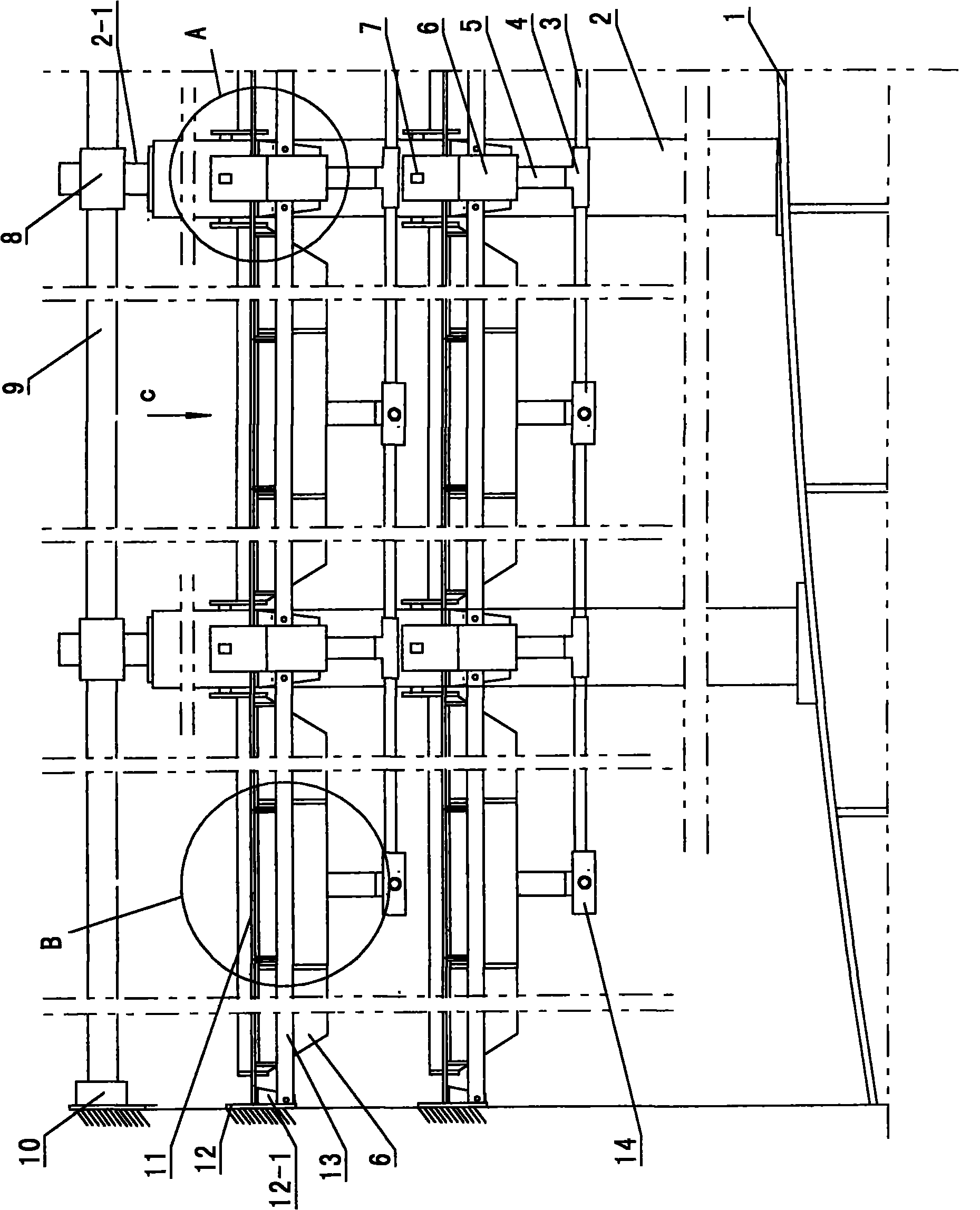

[0019] Following embodiment is the tray support structure of 12 meters tower diameter tray tower, figure 1 It is the supporting structure of its two-layer partial tray.

[0020] Such as figure 1 As shown, the load-bearing supports 1 at the bottom of the tower are distributed at equal intervals and fixed with 21 columns 2, each column is a square tube, and the end shaft 2-1 at the top is provided with a shaft sleeve 8 slidingly engaged therewith, and each shaft sleeve 8 Horizontal pull rods 9 are arranged between each bushing 8 and the tower wall located at the periphery. The so-called peripheral axle sleeves refer to the axle sleeves closest to the tower wall. One end of the horizontal tie rod 9 between the peripheral axle sleeves 8 and the tower wall of the embodiment is fixed to the connecting seat 10 of the tower wall.

[0021] The load-bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com