Beneficiation method for improving recovery rate of low-grade zinc oxide ore

A technology of zinc oxide ore dressing method, applied in flotation, solid separation, etc., can solve the problems of low grade and recovery rate of zinc concentrate, poor selectivity of flotation agents, and low resource utilization rate, so as to reduce infrastructure costs and The effects of management cost, simplification of pharmaceutical system, and low cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

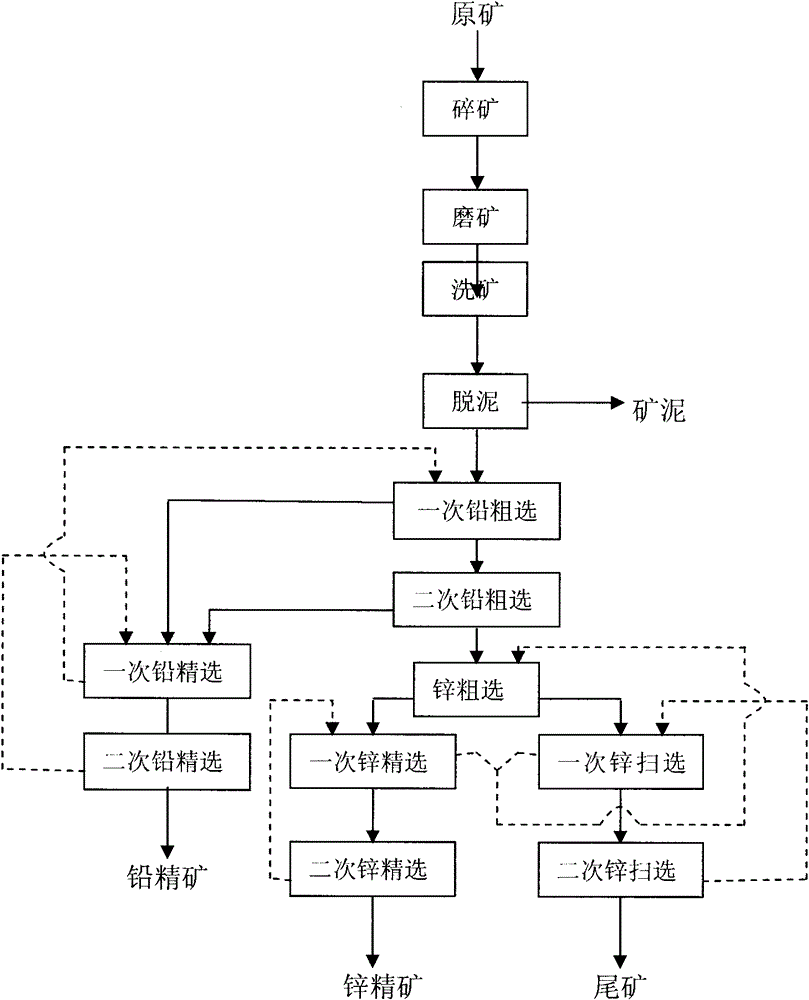

[0039] Such as figure 1 As shown, a beneficiation method to improve the recovery rate of low-grade zinc oxide ore is to wash ore at room temperature to remove impurities, mix oxide minerals and sulfide minerals, and use modified alkylamine zinc oxide chelating collector ZJ -5 Carry out zinc roughing and zinc sweeping, the method includes the following sequential process steps and conditions:

[0040] (a) ore crushing, the raw ore mixed with oxidized ore and sulfide ore is crushed together;

[0041] (b) Grinding, grinding the crushed raw ore to -0.074mm 60-76%;

[0042] (c) ore washing, washing the raw ore ground to -0.074mm 60-76%;

[0043] (d) desliming, desliming the raw ore after ore washing, and removing the slime;

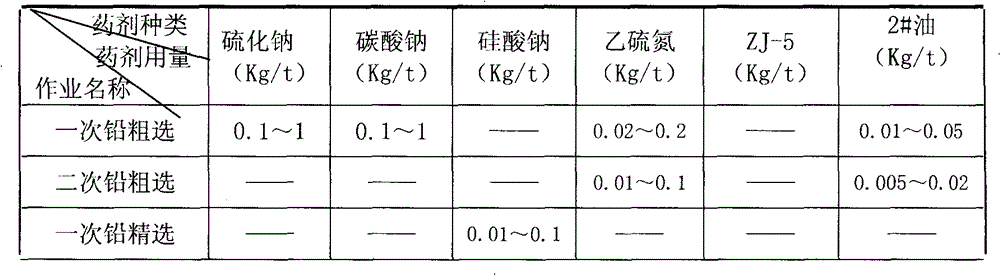

[0044] (e) primary lead roughing, add 0.1~1Kg sodium sulfide, 0.1~1Kg sodium carbonate, 0.02~0.2Kg ethyl disulfide nitrogen, 0.01~0.05Kg2# oil per ton to remove the raw ore to carry out primary lead roughing, Roughly select primary lead coarse ore and prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com