Rectilinear translation planar nine-bar mechanism and method for constructing a rectilinear translation motion mechanism

A translational motion and rod mechanism technology, applied in manipulators, manufacturing tools, mechanical equipment, etc., can solve the problems of low structural rigidity, low structural rigidity, and large occupied space, and achieve structural symmetry, high structural rigidity, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

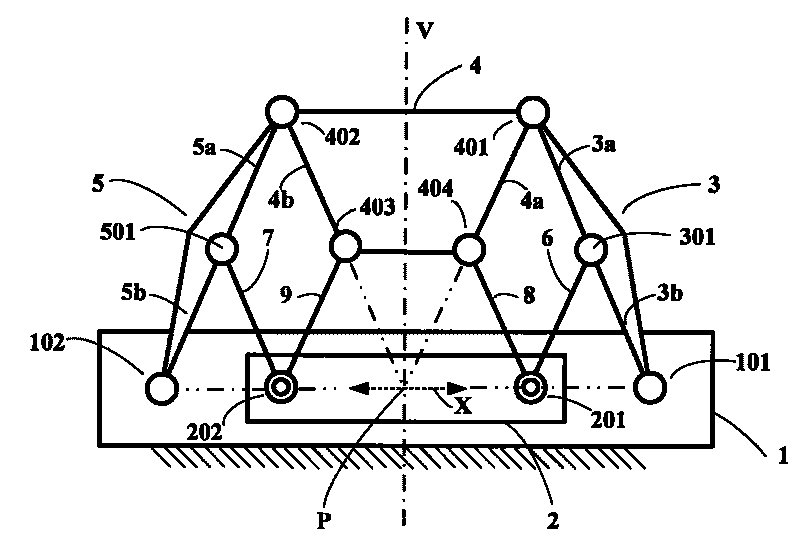

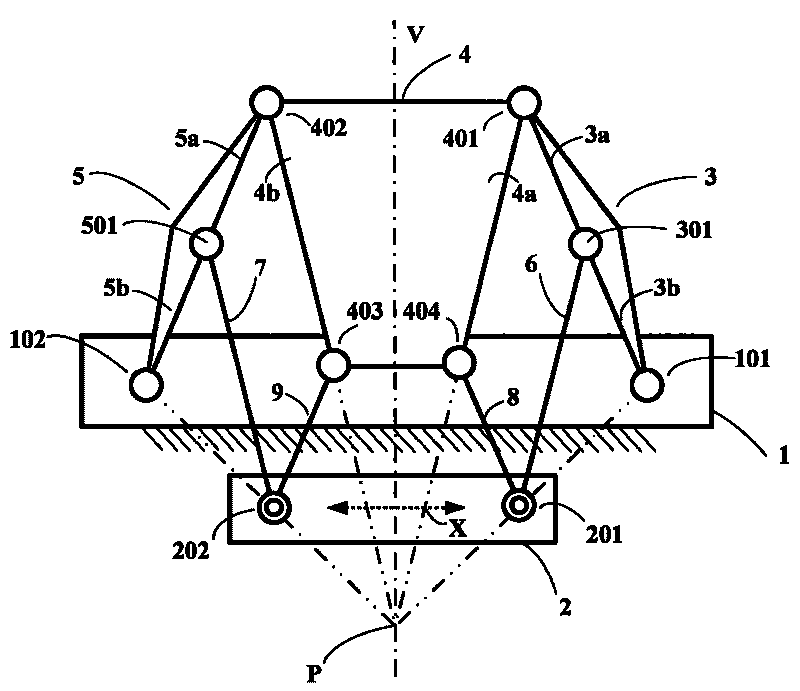

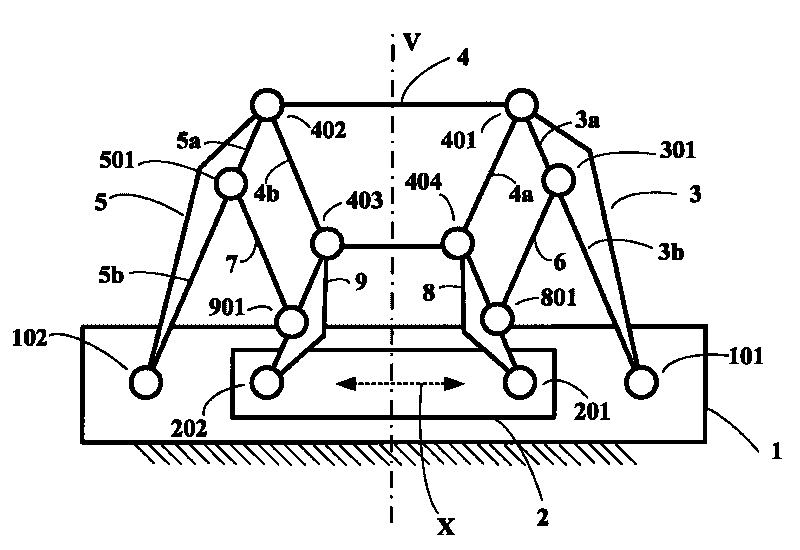

[0040] like Figure 1a Shown is a planar nine-bar mechanism with a single degree of freedom that produces high-precision linear translation motion, consisting of a frame 1, a motion platform 2, several rods 3, 4, 5, 6, 7, 8, 9 and several Hinges 101, 102, 201, 202, 301, 401, 402, 403, 404, 501 are formed. The frame 1 and the moving platform 2 are connected by rods 3, 4, 5, 6, 7, 8 and hinges 101, 102, 201, 202, 301, 401, 402, 403, 404, 501.

[0041] The planar 9-bar mechanism has a left-right symmetrical form, and is essentially a combination of a classic Roberts mechanism and two parallelogram scaling mechanisms. Classic Roberts institutions such as Figure 2a As shown, it is characterized in that the lengths of the two sides 4c and 4d of the rod 3, the rod 5 and the connecting rod 4 are equal. More generic Roberts institutions such as Figure 2b As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com