Method for installing automobile glass binding tape spike and hygroscope bracket

A technology of automotive glass and installation method, applied in windshield, transportation and packaging, motor vehicles and other directions, can solve the problems of low yield, large fluctuation of position deviation, unstable size and strength, etc. Product satisfaction, the effect of reducing the attachment installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

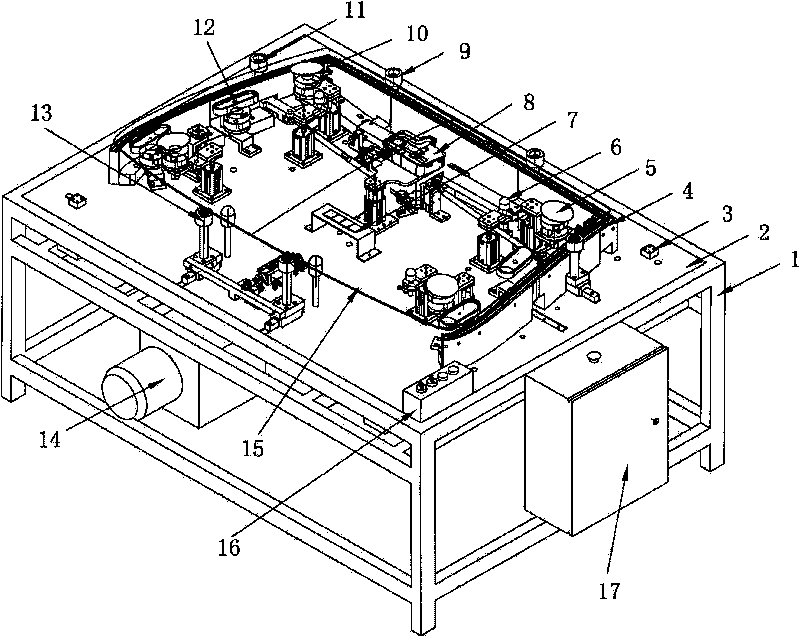

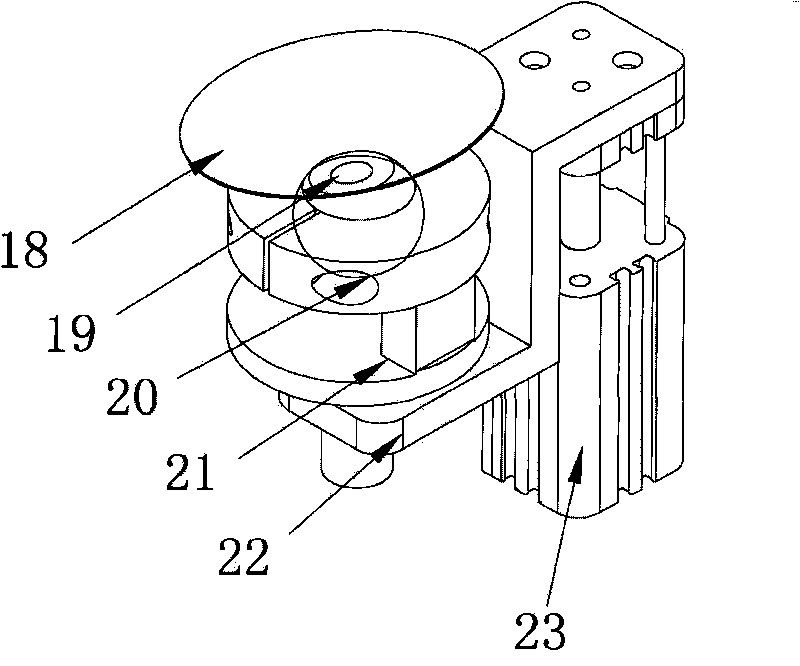

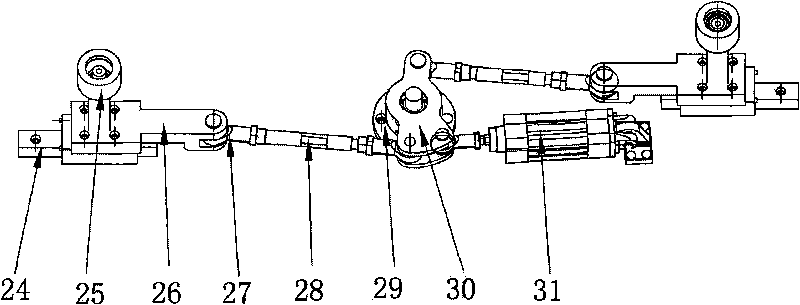

[0020] Such as Figure 1~3 Shown: An installation method for automotive glass edging strip studs and humidifier bracket. The equipment used includes underframe 1, base plate 2, edging strip fixing block 4, suction cup unit 5, ejector rod unit 6, and vacuum pressure gauge 7 , humidifier bracket module 8, glass small head positioning device 9, nail column installation unit 10, centering device 11, long suction cup 12, big head clamping device 13, vacuum pump 14, debugging control device 16, the surface flatness of the substrate 2 Processed to within ±0.1 mm, 3 to 4 reference blocks 3 are arranged on the substrate 2, and the substrate 2 is placed on the bottom frame 1 flatly. The edging strip fixing block 4 is made of BM5166 white substitute wood. After the edging strip fixing block 4 is processed, it is cut into 7 pieces. The bottom of the edging strip fixing block 4 is milled with a U-shaped groove for positioning, and is equipped with a positioning pin, the U-shaped groove is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com