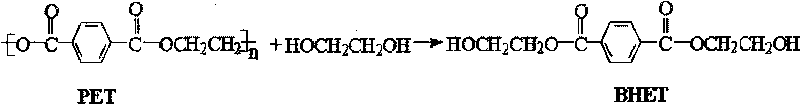

Method for catalytic-degrading polyethylene glycol terephthalate by dithionate

A technology of polyethylene terephthalate and diethylene phthalate, which is used in the preparation of carboxylate, catalysts for physical/chemical processes, organic chemistry, etc. Impurity, affecting the performance of reuse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

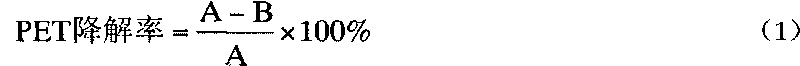

[0024] Implementation method: Add 10.0g PET particles, 20.0g ethylene glycol and 0.050g S 2 o 8 2- / ZnO. Control the reaction temperature at 170°C and the pressure at 1 atm, condense and reflux for 4 hours, then cool to room temperature, separate the undegraded PET particles, wash them thoroughly, dry them, and weigh them to obtain the mass of undegraded PET. Under these conditions, the conversion rate of PET polyester is 11.6%, and the yield of BHET is 0.4788%.

Embodiment 2

[0026] Same as Example 1, the reaction temperature is controlled to be 180°C. Under these conditions, the conversion rate of PET polyester is 37.5%, and the yield of BHET is 26.56%.

Embodiment 3

[0028] Same as Example 1, the reaction temperature is controlled to be 190°C. Under these conditions, the conversion rate of PET polyester is 55.6%, and the yield of BHET is 30.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com