Ventilation liquid-preventing stop valve

A shut-off valve and liquid-blocking technology, applied in the cooling of engine components, machines/engines, and engines, etc., can solve the problems that the cooling system cannot meet the cooling effect, the engine warm-up time is long, and the heating effect is not good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

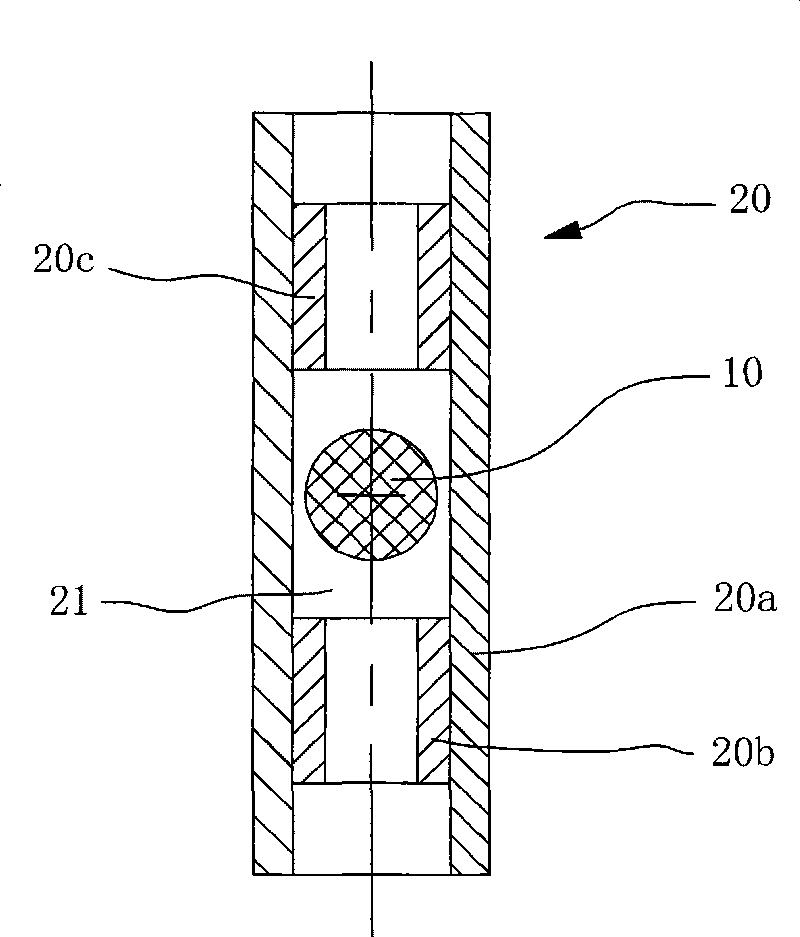

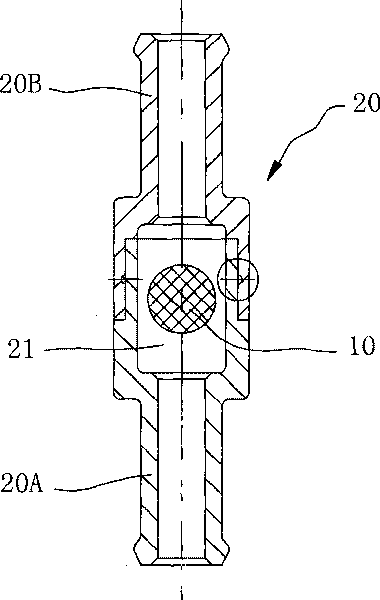

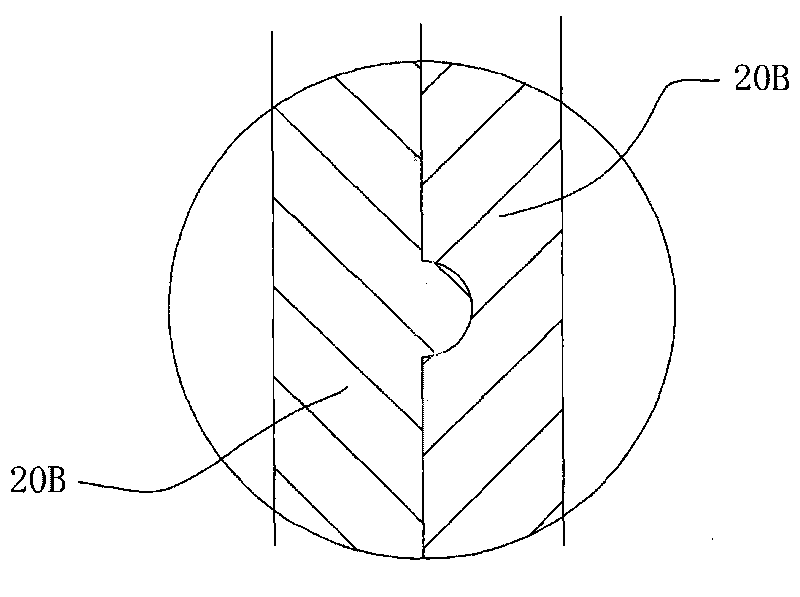

[0009] Such as figure 1 , 2 As shown, the present invention provides a venting and liquid blocking stop valve, which can be used on the engine outlet pipe to realize the functions of venting and liquid blocking. Specifically, it can ensure the removal of gas and prevent the discharge of coolant at the same time. The technical solution includes a cavity 21 for accommodating the piston 10, the cavity 21 is located in the valve body 20, the valve body 20 is provided with input and output pipelines 22, 23, and the junction of the input and output pipelines 22, 23 and the cavity 21 The diameter of the hole is smaller than the cross section of the piston 10. The piston 10 can move or float or swim in the cavity 21, and the gas discharged through the engine outlet pipe enters the ventilation and liquid resistance stop valve and is discharged smoothly, and when there is liquid discharged, the force of the liquid is relatively large, which will push the piston 10 Move and block the i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap