Side-light type backlight source and drive method thereof

A driving method and backlight technology, applied in the field of backlight, can solve the problems of inability to change the luminance and gradation of luminance of the backlight, and achieve the effects of avoiding uneven brightness, improving service life, and shortening lighting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

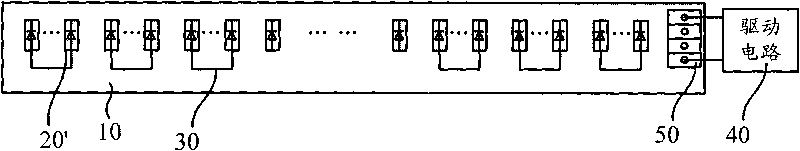

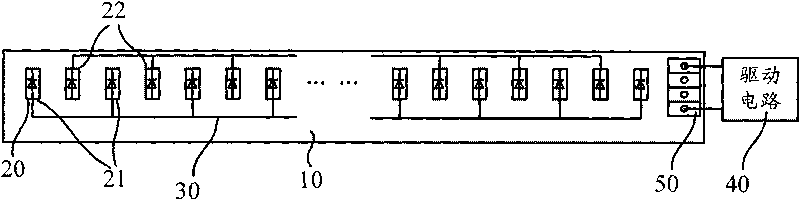

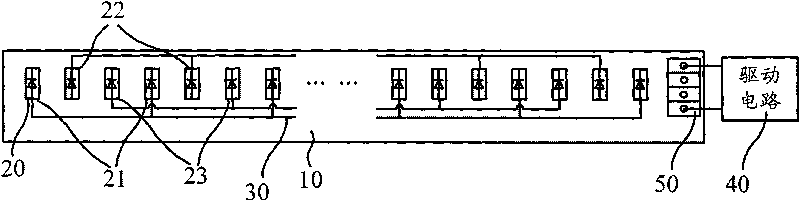

[0019] figure 2 It is a structural schematic diagram of the first embodiment of the edge-lit backlight of the present invention. Such as figure 2 As shown, the edge-lit backlight includes a circuit board 10 , point light sources 20 arranged in a row and outlet terminals 50 . Wherein the specific setting and connection methods of the point light sources 20 are: all point light sources 20 in a row are divided into two groups, the point light sources 20 at odd positions are the first group 21, and the point light sources 20 at even positions are the second group 22 , the point light sources 20 in the first group 21 and the point light sources 20 in the second group 22 are spaced apart from each other; the point light sources 20 in each group are connected in series, and the first group 21 and the second group 22 are connected to the outlet terminal through the line 30 50, in order to connect the drive circuit 40.

[0020] The drive circuit can be a constant current drive cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com