Non-contact real-time displacement measuring method and device in bending deformation process of work piece

A technology of bending displacement and workpiece, applied in the field of non-contact real-time displacement measurement and device in the process of workpiece bending deformation, can solve the problems of unobtainable bending displacement change, scanning interruption, etc., to improve repeatability, reliability and accuracy Improve and promote the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

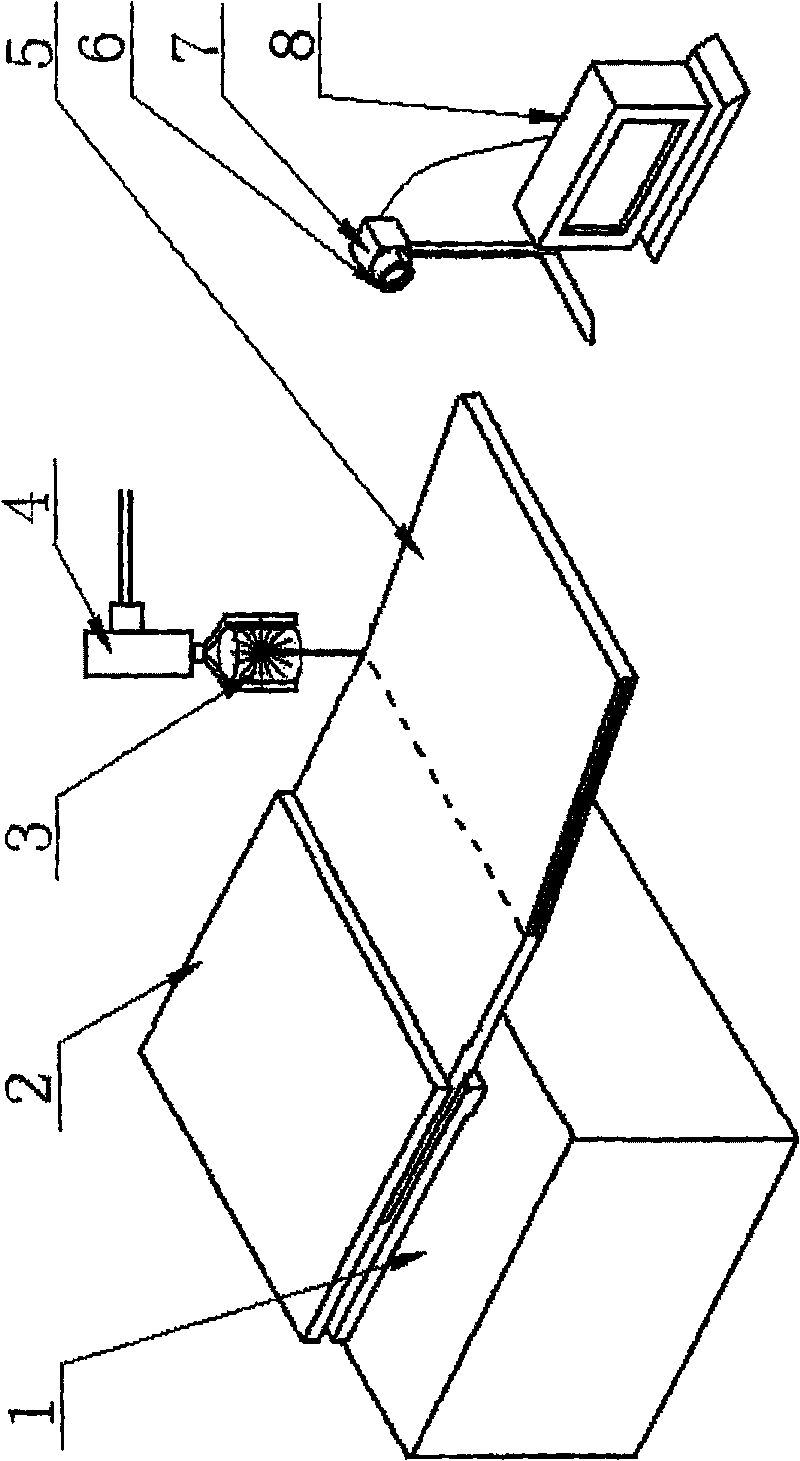

[0026] figure 1 A laser bending system according to a preferred embodiment of the present invention is shown. The laser bending system shown comprises a table 1 equipped with a fixture 2 essentially consisting of two plates that can be pressed against each other in order to hold and clamp a workpiece 5 between them. The workpiece 5 to be deformed, which is a sheet metal in the present embodiment, is held by the clamp 2 like a cantilever plate. figure 1 The system also includes a laser device 3 for providing a laser beam, which is mechanically connected to a robot 4 for moving the laser device 3 . Robot 4 moves and controls laser device 3 so that laser light is irradiated on metal sheet 5 along the width direction of sheet metal ( figure 1 dashed line shown). Furthermore, the present system includes a CCD camera 7 . The lens of the camera 7 is covered with a filter 6 to prevent laser light from entering the camera 7 . In order to calculate the optical data obtained by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com