Train moving die experiment system

An experimental system and dynamic model technology, applied in aerodynamic tests, railway vehicle tests, measuring devices, etc., can solve the problems of increased running speed, insufficient power, small model ratio, etc., to achieve increased volume and weight, Increased acceleration power and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

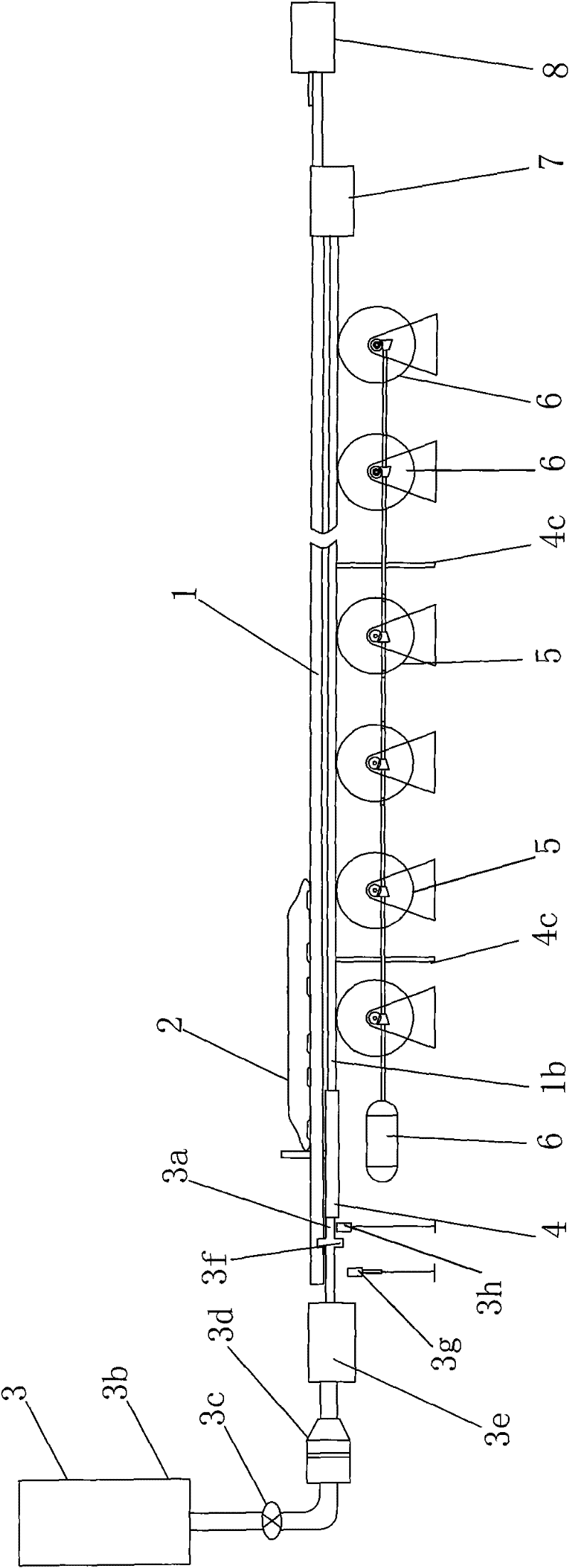

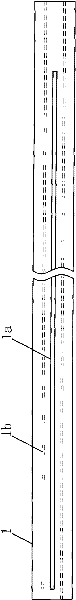

[0027] figure 1 , 2 As shown, a specific embodiment of the present invention is: a train dynamic model experiment system, including a line support 1, a test vehicle 2 on the line support 1, and a power device behind the test vehicle 2. Power unit is made up of compressed air ejection mechanism 3, cart 4 and flywheel acceleration mechanism, wherein:

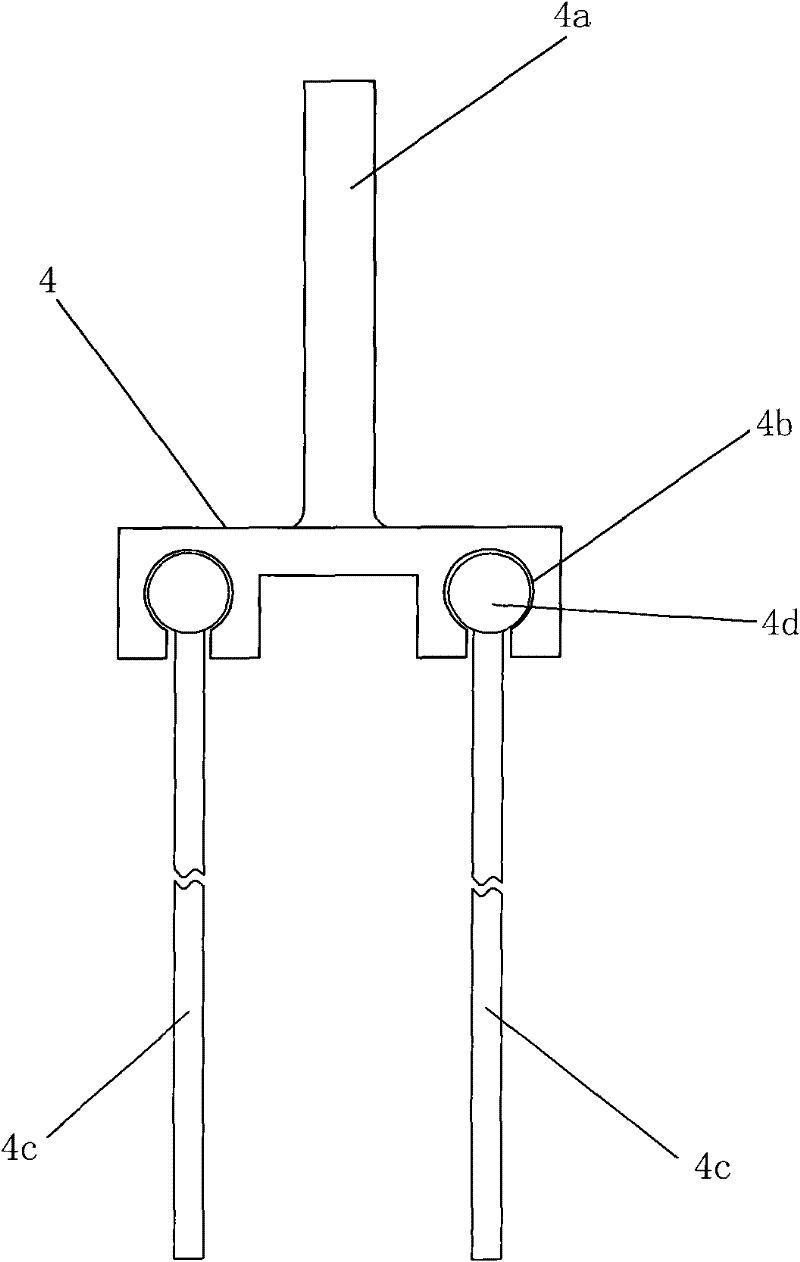

[0028] The flywheel acceleration mechanism is composed of a plurality of flywheels driven by the motor 6 under the rear area of the line support 1. The vertical position of the trolley 4 is between the flywheel acceleration mechanism and the line support 1, and the horizontal position is between the test vehicle. 2 and the compressed air ejection mechanism 3, the push rod 4a on the upper surface of the trolley 4 passes through the guide groove 1a of the line support 1 upwards and is aligned with the rear of the test vehicle. The cart interceptor 7 and the hydraulic cart interceptor 7 have the same vertical position as the cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com