Method for rapid generation of three-dimensional surface model through numerical control processing program codes

A technology of three-dimensional curved surfaces and processing programs, applied in program control, general control systems, simulators, etc., can solve the problems of unsatisfactory fast display processing speed, complex surface splicing process, poor smoothness of approximate curved surfaces, etc., and achieve a mobile observation angle Smooth, faster display, faster processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

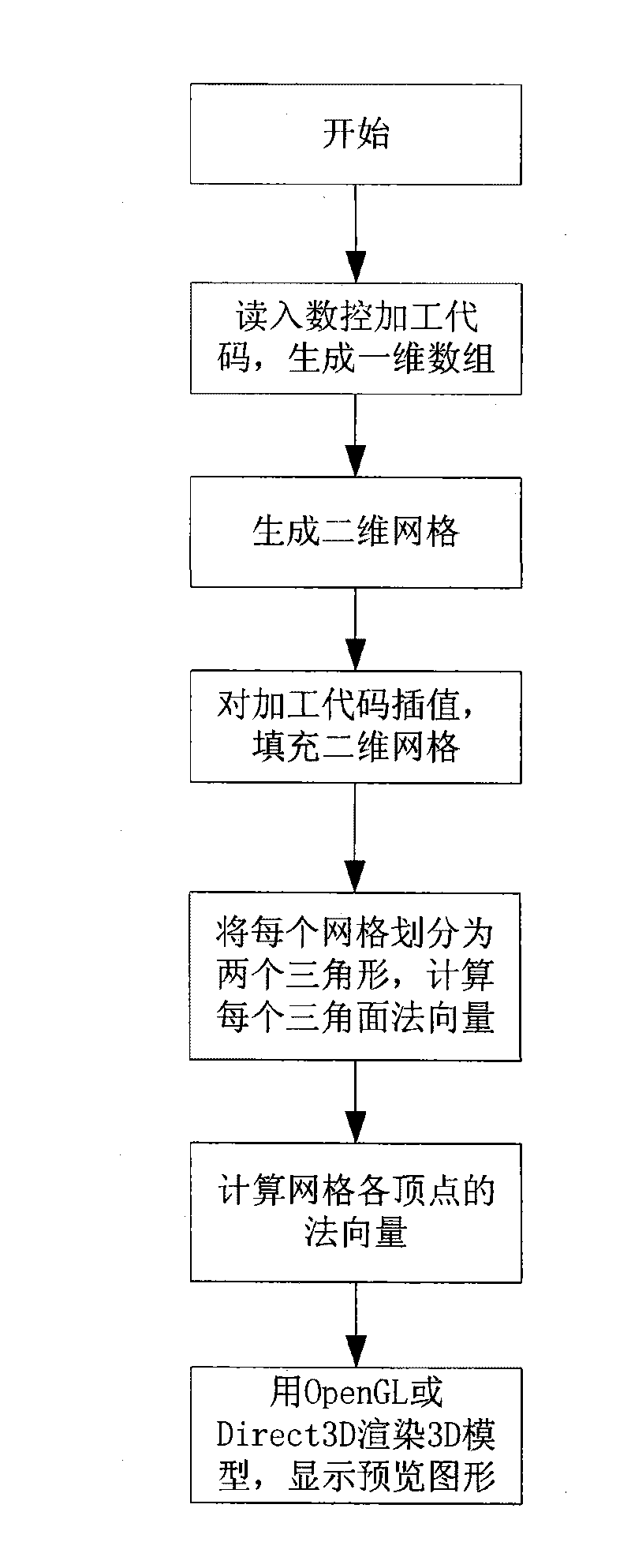

[0020] Such as figure 1 Shown is the realization principle flowchart of the present invention, and the concrete method of generating three-dimensional surface model in the invention is:

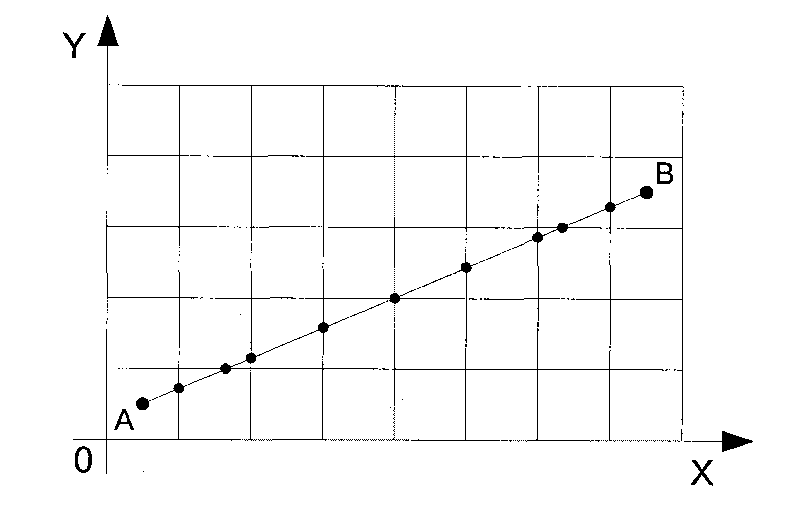

[0021] Step 1 Analyze the NC machining code, and take out the moving coordinate points of the tool path. Save the coordinate points (X, Y, Z) into a one-dimensional array M[N], where each array element contains three coordinate values of X, Y, and Z, which are composite type elements, and the length N of the array is NC machining The number of coordinate points in the code.

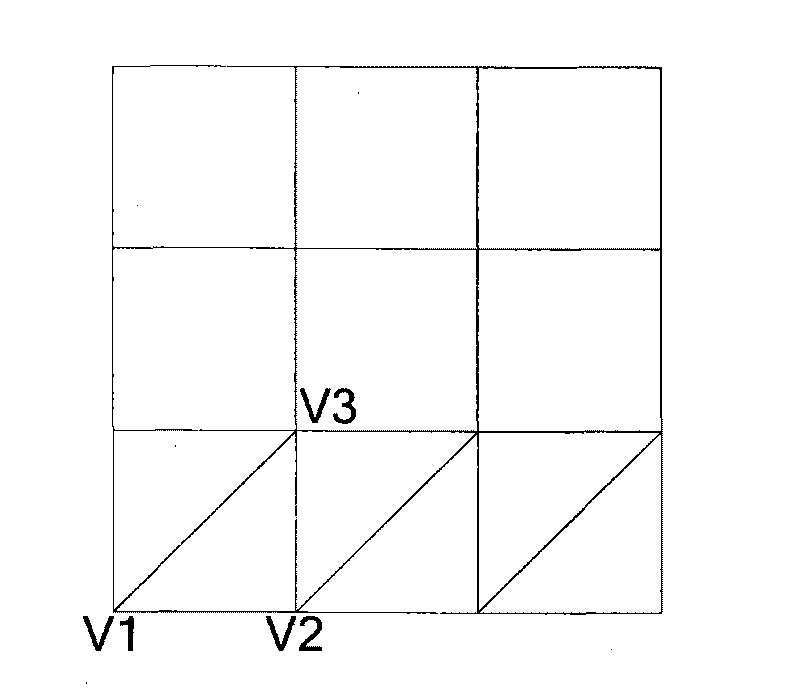

[0022] Step 2. Set a surface display accuracy constant C, calculate the maximum and minimum values of the X and Y coordinates in the array M, and obtain the size range Xrang and Yrang of the X and Y coordinates, and display according to the size range of the X and Y coordinates and the curved surface precision, create a two-dimensional array of float P[Lx][Ly].

[0023] Among them: surface display accuracy constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com