Long-travel high-accuracy multiple-degree-of-freedom planar motor

A plane motor, long stroke technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of limited mover stroke, complex control, low positioning accuracy, etc., and achieve the effect of high degree of freedom and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

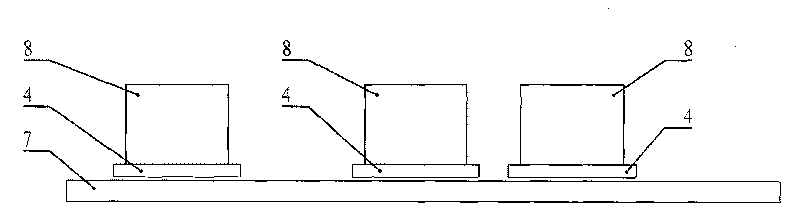

[0009] Specific implementation mode one: see figure 1 This embodiment will be described. The long-stroke high-precision multi-degree-of-freedom planar motor described in this embodiment includes a stator 7 of a long-stroke planar motor, i movers 4 of a long-stroke planar motor and i short-stroke multi-degree-of-freedom magnetic levitation planar motors 8, A short-stroke multi-degree-of-freedom magnetic levitation planar motor 8 is fixed on the mover 4 of each long-stroke planar motor, and each short-stroke multi-degree-of-freedom magnetic levitation planar motor 8 is composed of a short-stroke planar motor and a magnetic levitation support device. The magnetic levitation support device includes m magnetic levitation support mechanisms, the stator of the short-stroke planar motor is fixedly connected to the mover of the long-stroke planar motor, and the m magnetic levitation support mechanisms are all distributed around the stator of the short-stroke planar motor, and The sta...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and the long-stroke, high-precision, multi-degree-of-freedom planar motor described in Embodiment 1 is that the m is 3, that is, each set of magnetic levitation support mechanisms is composed of three magnetic levitation support mechanisms 1, so The three magnetic levitation support mechanisms 1 are 120° apart from each other.

specific Embodiment approach 3

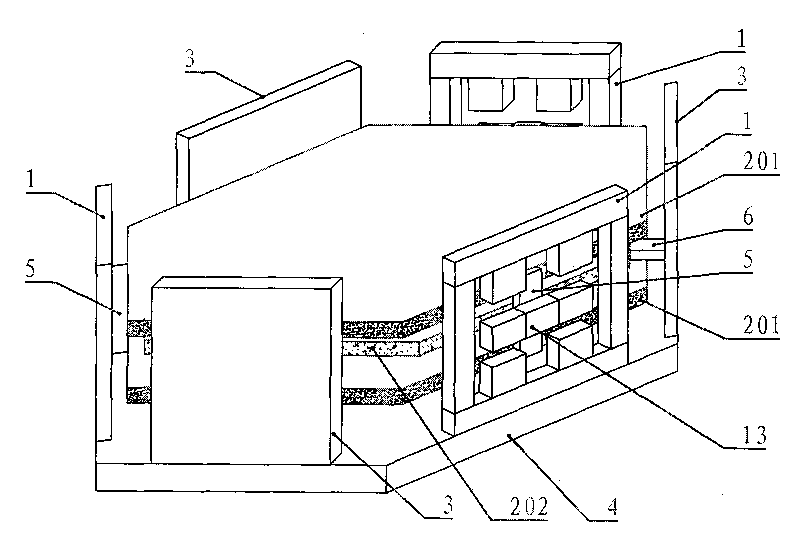

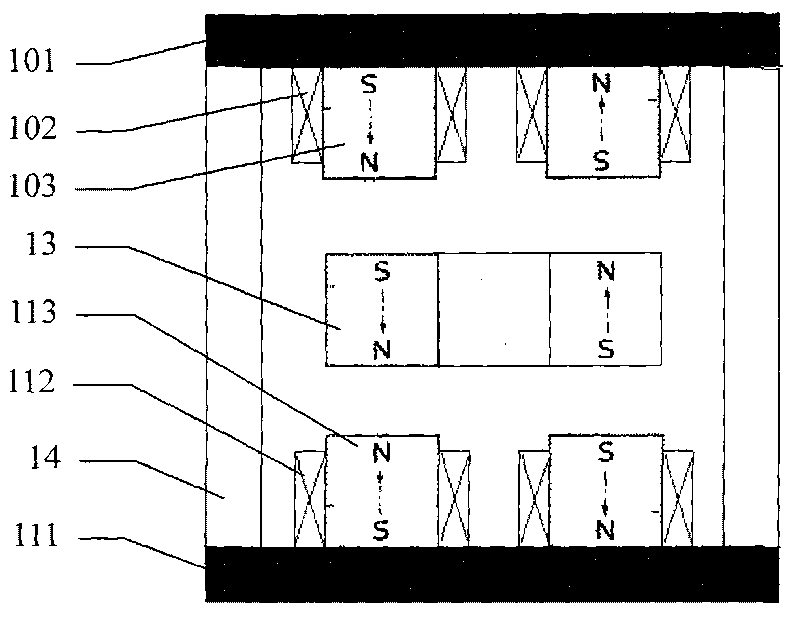

[0012] Embodiment 3: This embodiment is an embodiment of the short-stroke multi-degree-of-freedom magnetic levitation planar motor 8 described in Embodiment 2. see figure 2 As shown, the short-stroke planar motor 2 in the figure is a regular hexagonal bilateral structure with a symmetrical structure, and the permanent magnet excitation component arrays on both sides are movers 202, and the middle armature component is a stator 201, of which three The magnetic levitation support mechanisms 1 are fixed on the upper surface of the base plate 4 at 120° to each other, and the three support frames 3 are fixed on the upper surface of the base plate 4 at 120° to each other, and the three magnetic levitation support mechanisms 1 and the three support Frames 3 are arranged alternately to form a regular hexagon with a symmetrical structure. The short-stroke planar motor is located in a regular hexagon with a symmetrical structure surrounded by three magnetic levitation support mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com