Parallel IGBT module copper bar installation structure

An installation structure and parallel technology, applied in the direction of output power conversion devices, electrical components, etc., can solve the problems of inconvenient installation, uncompact structure, module damage, etc., and achieve the effect of easy installation, compact structure and good current sharing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

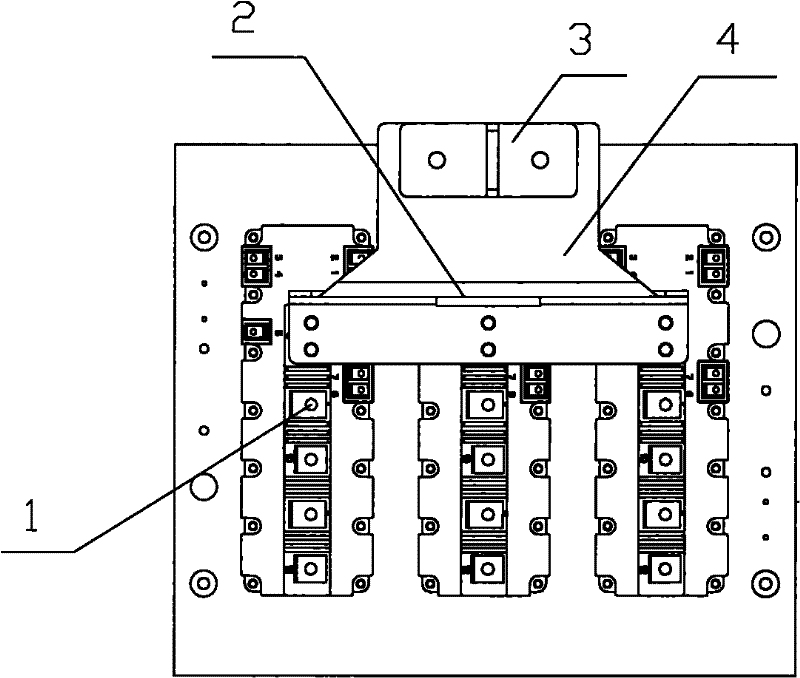

[0014] See attached figure 1 shown.

[0015] The transfer copper bar 3 is centrally and fixedly installed on the upper part of the short-circuit copper bar 4 , and the three IGBT modules 1 are installed on the lower part of the short-circuit copper bar 4 through the mounting holes provided on the short-circuit copper bar 4 . Between the transfer copper bar 3 and the installation position of the IGBT module 1 on the short-circuit copper bar 4, a current-blocking slot 2 is opened on the body of the short-circuit copper bar 4, and the current-blocking slot 2 is centered On the short-circuit copper bar 4. The three IGBT modules 1 are connected to the short-circuit copper bar 4 , so that the current flowing through each IGBT module 1 is basically the same, and evenly flows to the transfer copper bar 3 through the short-circuit copper bar 4 . The short-circuit copper bar 4 is provided with a long slot hole 2 for blocking current on the substrate, which changes the current path and...

Embodiment 2

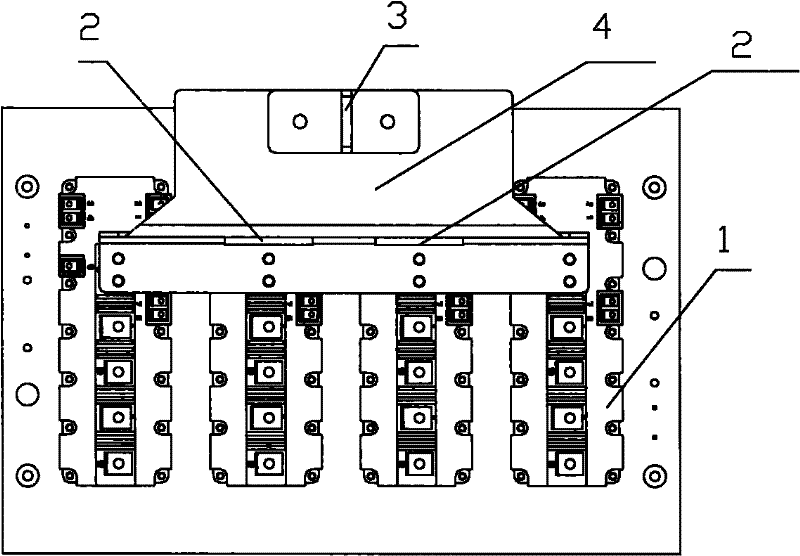

[0017] See attached figure 2 shown.

[0018] The transfer copper bar 3 is centrally and fixedly installed on the upper part of the short-circuit copper bar 4 , and the four IGBT modules 1 are installed on the lower part of the short-circuit copper bar 4 through the mounting holes provided on the short-circuit copper bar 4 . Between the transfer copper bar 3 and the installation position of the IGBT module 1 on the short-circuit copper bar 4, there are two current-blocking slots 2 on the body of the short-circuit copper bar 4, and the current-blocking slot 2 is centered Open on the short-circuit copper bar 4. The four IGBT modules 1 are connected to the short-circuit copper bar 4 , so that the current flowing through each IGBT module 1 is substantially the same, and evenly converged to the transfer copper bar 3 through the short-circuit copper bar 4 . The short-circuit copper bar 4 has two long slots 2 for blocking current on the substrate, changing the current path and achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com