Mine rockfall braking rope friction plate drum damper

A technology of braking ropes and friction plates, applied in elevators, transportation and packaging, etc., can solve the problems of uncertain braking force of steel rope helical buffers, affecting the deformation resistance of braking steel ropes, and deceleration damage to human health, etc., to achieve a solution Uncertain braking force, convenient adjustment of frictional braking force, and convenient braking force test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

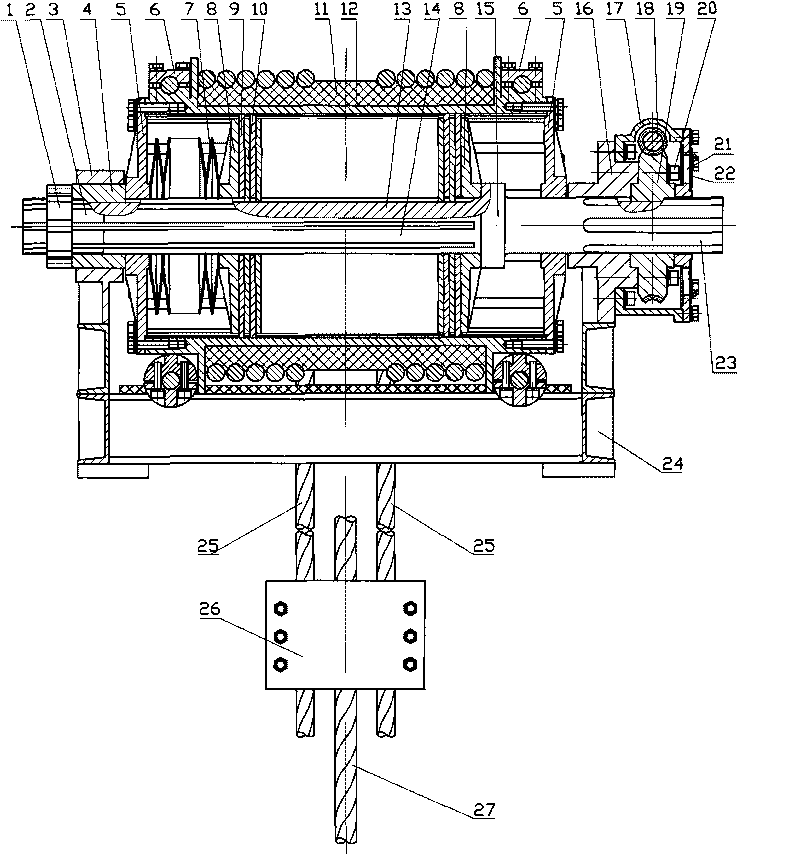

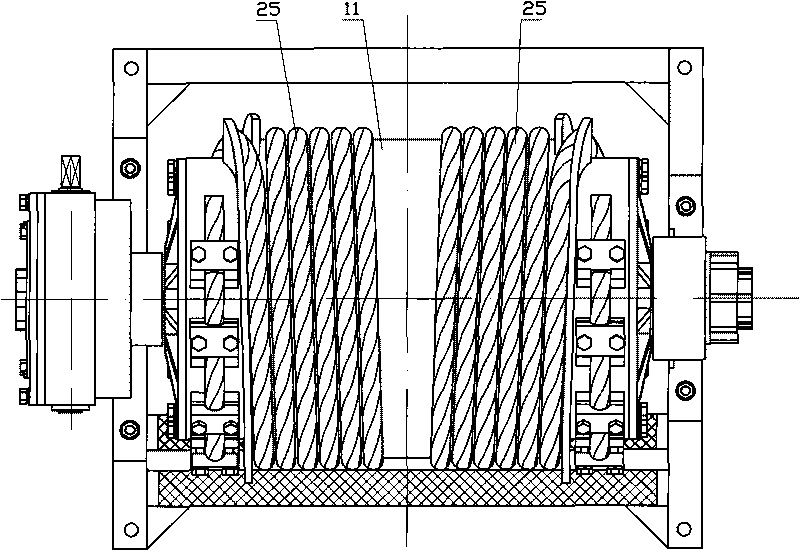

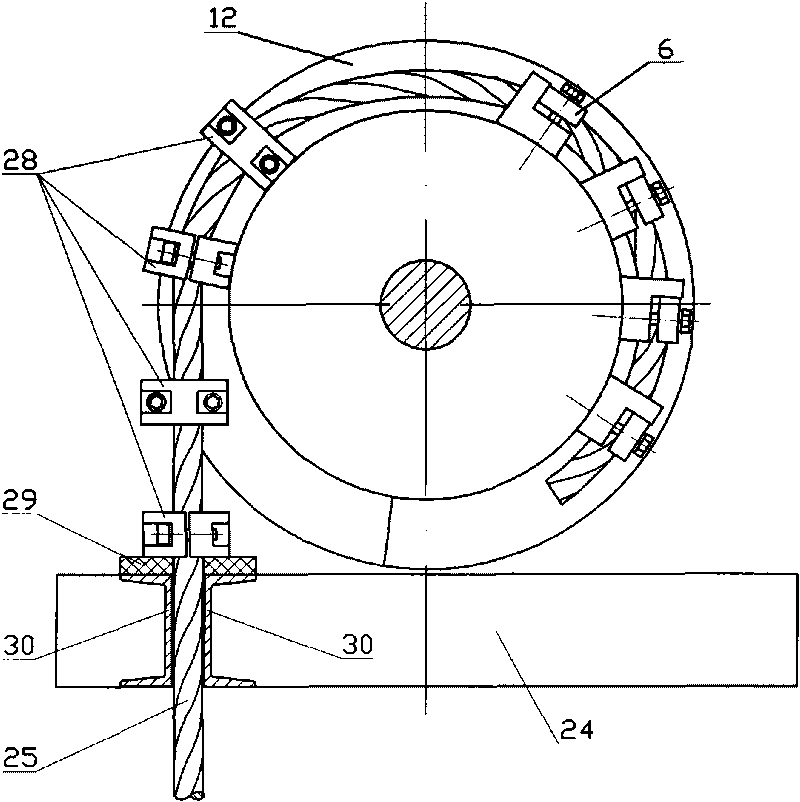

[0017] Such as figure 1 As shown, the mine anti-fall brake rope friction plate reel buffer is composed of a buffer rope 25, a reel 12, an end cover 5, a main shaft 13, a shaft sleeve 4, an outer friction plate 9, an inner friction plate 10, a compression spring 7. Adjusting nut 1, free bearing 3, lock shaft bearing 16, flange worm wheel 19, safety fixing pin 20, base 24, etc.; main shaft 13 is provided with threaded section 2, brake section 14, shaft shoulder 15 and lock shaft Section 23; two end caps 5 are arranged at both ends of the reel to form a cavity drum; the end caps are provided with shaft holes, the main shaft 13 passes through the shaft holes of the end caps, and the braking section 14 and the shaft shoulder 15 are arranged on the drum In the cavity, the threaded section 2 and the shaft locking section 23 are arranged outside the drum cavity, the two ends of the main shaft 13 are arranged in the free bearing 3 and the shaft locking bearing 16, and the free bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com