Water-base ink cleaning agent

A cleaning agent and ink technology, applied in the direction of chemical paint/ink remover, coating, etc., can solve the problems of strong volatility of butyl cellosolve, chronic poisoning of human internal organs, and unsatisfactory cleaning effect, so as to improve the ability of hard water resistance , Strong degreasing ability, good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

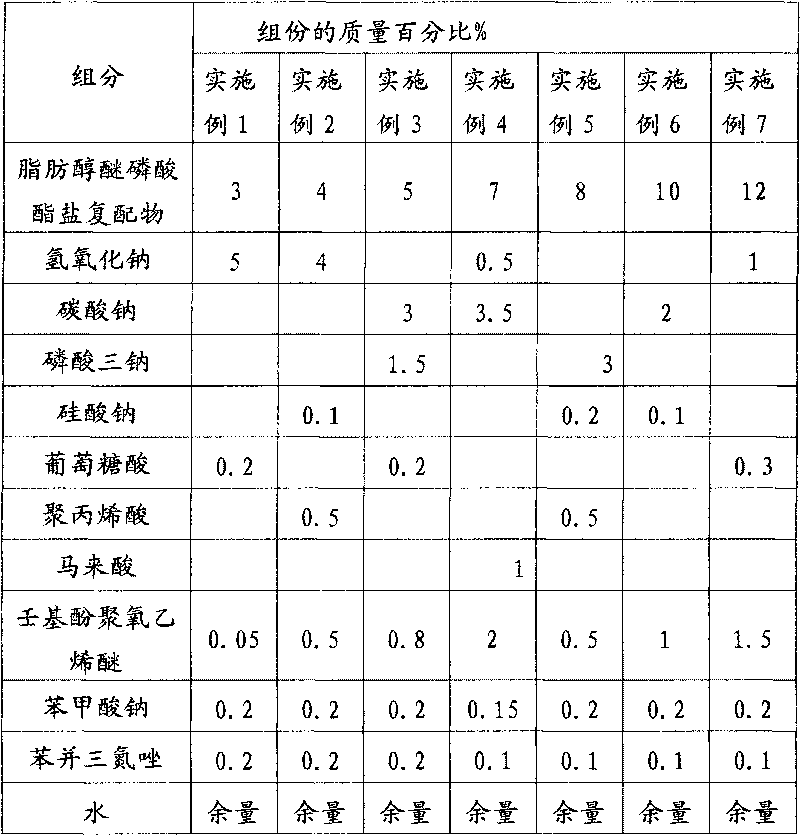

[0028] Embodiment 1-7 Preparation of water-based ink cleaning agent of the present invention

[0029] At normal temperature, according to the ratio shown in Table 2, the amount of fatty alcohol ether phosphate salt compound required will be calculated according to the total amount of ink cleaning agent to be prepared, and then MOA-3PK and NP- 4PK mixed, and then weighed the rest of the components according to the proportion. Under normal temperature conditions, first add the basic inorganic substance and co-solvent into the water, stir and dissolve completely, then add the above-mentioned other substances, stir until completely transparent.

[0030] Table 2 Composition and proportion of ink cleaning agent

[0031]

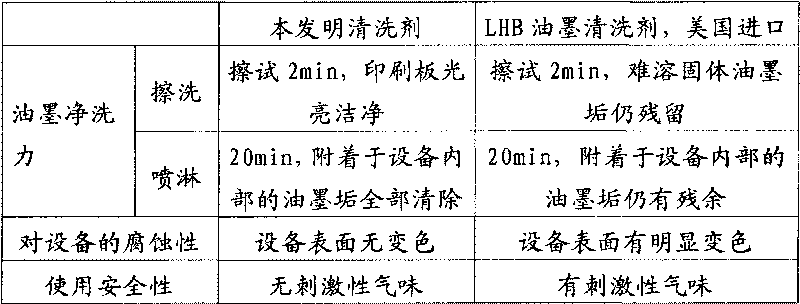

[0032] 20 kilograms of ink cleaning agents prepared from the above-mentioned examples are used as diluents with water at a dilution ratio of 1: 30, and its usage method is divided into two kinds:

[0033] (1) Scrub. Dip the diluent with a cloth, and manually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com