On-line cleaning and de-dusting element of heat exchange tube with directional tail wing

A heat exchange tube and tail fin technology is applied in the field of on-line cleaning and descaling elements of heat exchange tubes, which can solve the problems of horizontal blocking of heat exchange tubes, inability to control movement, clogging and cleaning effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

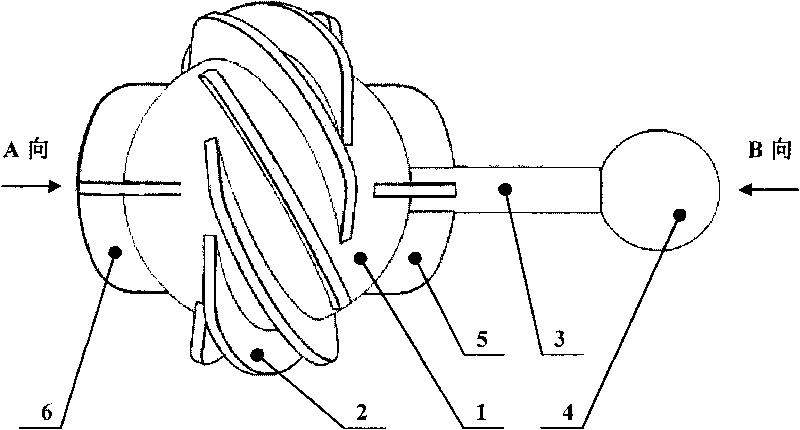

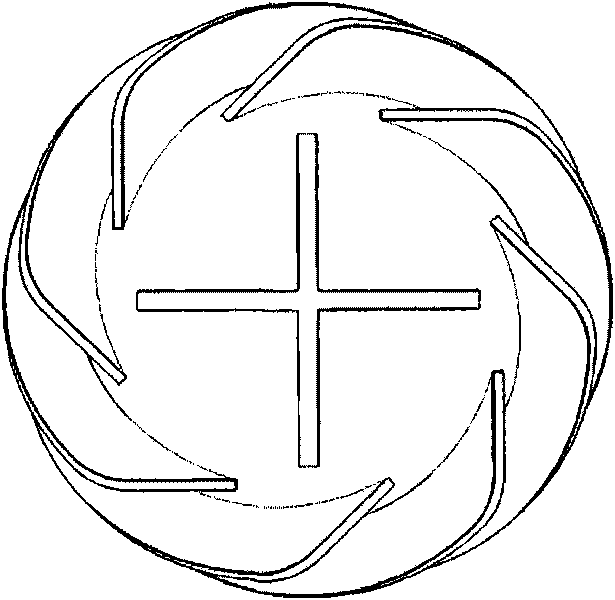

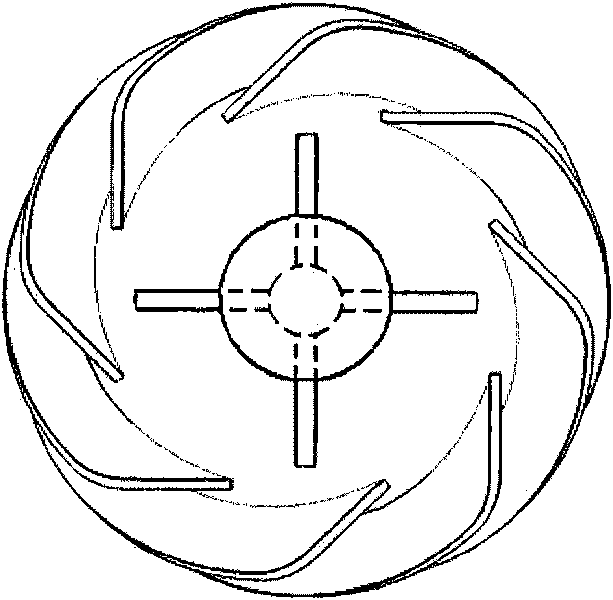

[0023] Such as figure 1 As shown, the present invention includes a solid rubber ball 1, a plurality of inclined fins 2 uniformly arranged on the surface of the ball, a directional tail post 3, a small ball 4, crossed front wings 6 and rear wings 5. The tail ball 4 that the directional tail post 3 and the tail post end are connected forms the directional tail fin. figure 2 It is a schematic diagram of Embodiment 1 of the present invention in direction A. image 3 It is a schematic diagram of Embodiment 1 B of the present invention. Figure 4 It is a schematic diagram of the working principle of Embodiment 1 of the present invention, and 7 in the figure is the inside of the heat exchange tube to be cleaned. Figure 5 It is a schematic diagram of the working principle of the cleaning ball without tail fins. As a comparison with the working principle of the present invention, 7 is in the heat exchange tube to be cleaned, and 8 is a cleaning ball without tail fins.

[0024] In ...

Embodiment 2

[0032] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the directional tail is composed of a cylinder and a plurality of fins (tail fins) arranged at the tail of the cylinder. Replacing the tail ball with the tail fin can further enhance the cleaning and descaling effect of the tail fin, but the disadvantage is that it is easy to wear.

Embodiment 3

[0034] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is: the directional tail is made up of a column (tail post), and its structure is simpler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com