High power factor DCM Boost PFC converter

A high power factor, converter technology, applied in the direction of AC power input conversion to DC power output, output power conversion device, high-efficiency power electronic conversion, etc., can solve the problem of low input power factor, achieve high input power factor, Effects of reduced inductor current ripple and reduced conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] 1 Working principle of DCM Boost PFC converter

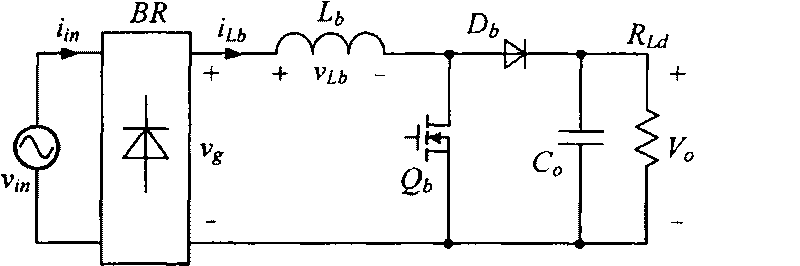

[0025] attached figure 1 It is the main circuit of the Boost PFC converter. For the convenience of analysis, the following assumptions are first made: 1. All devices are ideal components; 2. The output voltage ripple is very small compared with its DC value; 3. The switching frequency is much higher than the input voltage frequency.

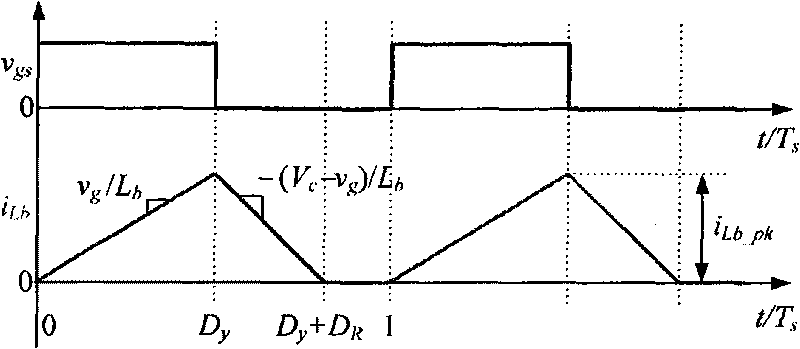

[0026] attached figure 2 The inductor current waveform in one switching cycle during DCM is given. When Q b When turned on, D b cutoff, the boost inductor Lb The voltage across it is v g , its current i Lb start with zero and start with v g / L b The slope increases linearly. When Q b When shutting down, i Lb by D b freewheeling, at this time L b The voltage across it is v g -V o , i Lb With (V o -v g ) / L b the slope of the drop. Since the Boost converter works in DCM mode, before the end of the switching cycle, i Lb down to zero.

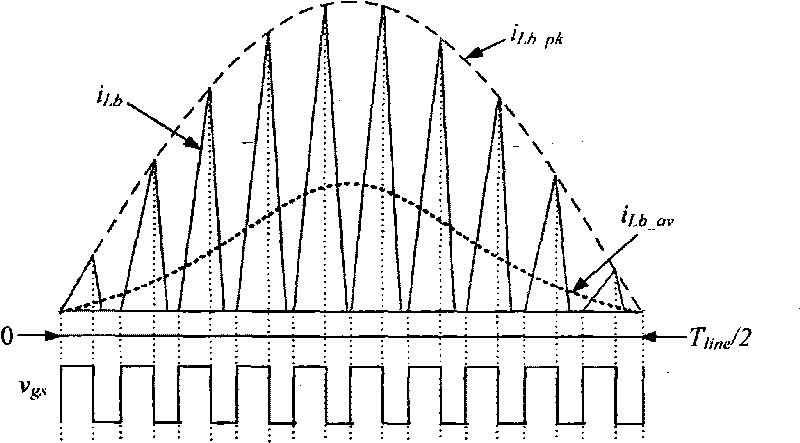

[0027] Without loss of generality, le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com