Casting with isolation layer and manufacture method thereof

A manufacturing method and isolation layer technology, applied in the direction of manufacturing tools, non-electric welding equipment, welding equipment, etc., can solve problems affecting driving safety, corrosion cracking, flavanic corrosion, etc., achieve good quality and reliability, avoid The effect of the corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

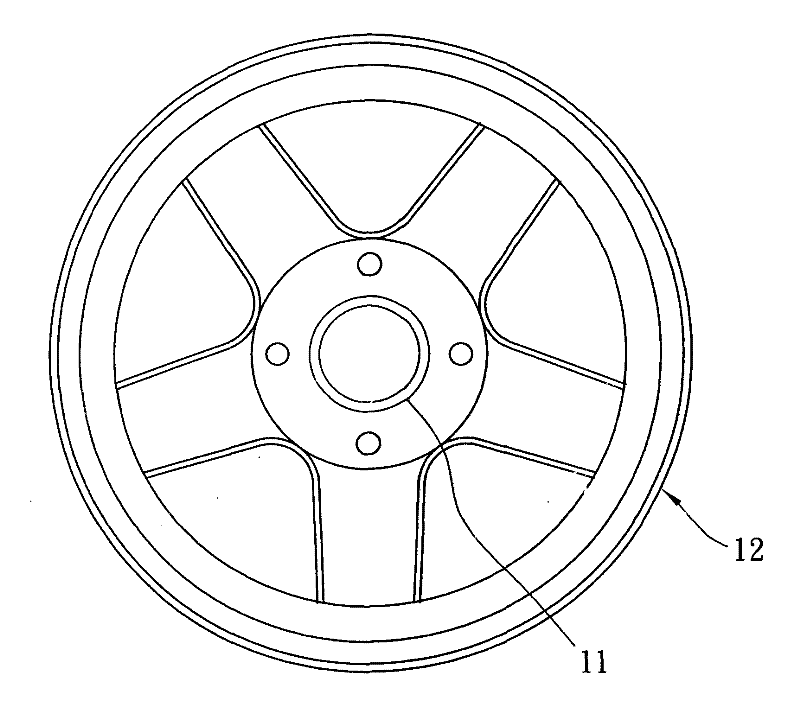

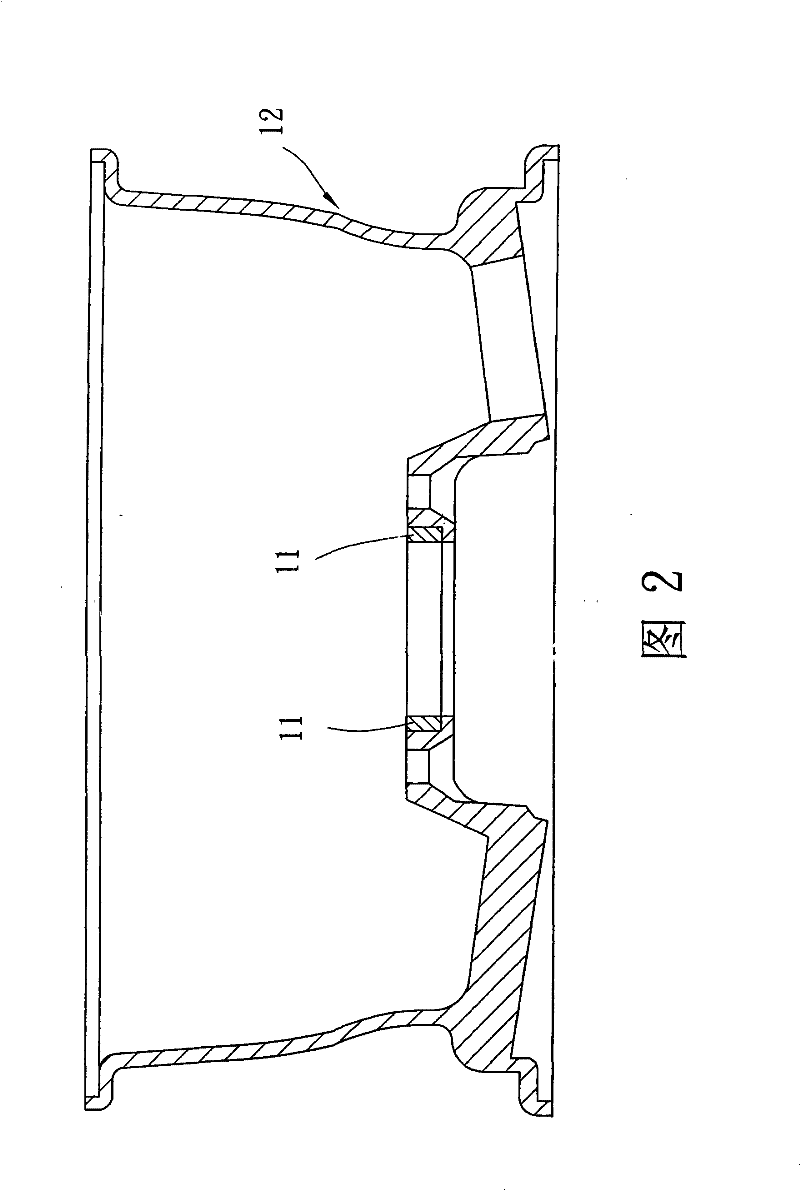

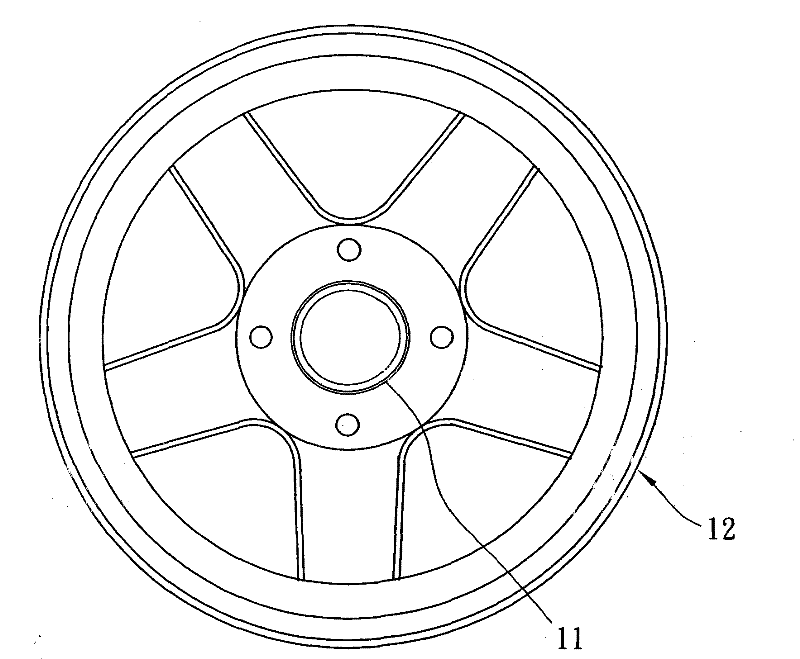

[0026] refer to image 3 , Figure 4 , Figure 5 ,like image 3 , Figure 4 The casting shown with the isolation layer, is made of such as Figure 5 The casting with the isolation layer is produced in a preferred embodiment of the manufacturing method. Here, the casting is illustrated by taking a car / motorcycle wheel rim as an example, but the application of the present invention is not limited thereto.

[0027] refer to image 3 , Figure 4 , the casting with the isolation layer includes an insert 2 and a casting blank 3 .

[0028] The insert 2 has a base material 21 mainly comprising iron, and an insulating layer 22 composed of an alloy comprising a first metal element. In this embodiment, the base material 21 is the inner edge frame of the rim , the base material 21 is selected from stainless steel, cast iron, or steel. In this embodiment, the base ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com