Novel vibrating finisher

A finishing machine, a new type of technology, applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc., can solve the problems of short service life, high replacement frequency, low work efficiency, etc. Achieve the effect of improving surface roughness, improving production progress and prolonging service life

Inactive Publication Date: 2010-07-07

大连隆正光饰机制造有限公司

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above-mentioned vibrating finishing machine has a single appearance and is not beautiful enough

The grinding tank of the polishing machine needs to be lined with polyurethane, which has a complex structure, and the polyurethane lining is not wear-resistant, the service life is short, the replacement frequency is high, the time for polishing parts is relatively long, and the work efficiency is relatively low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

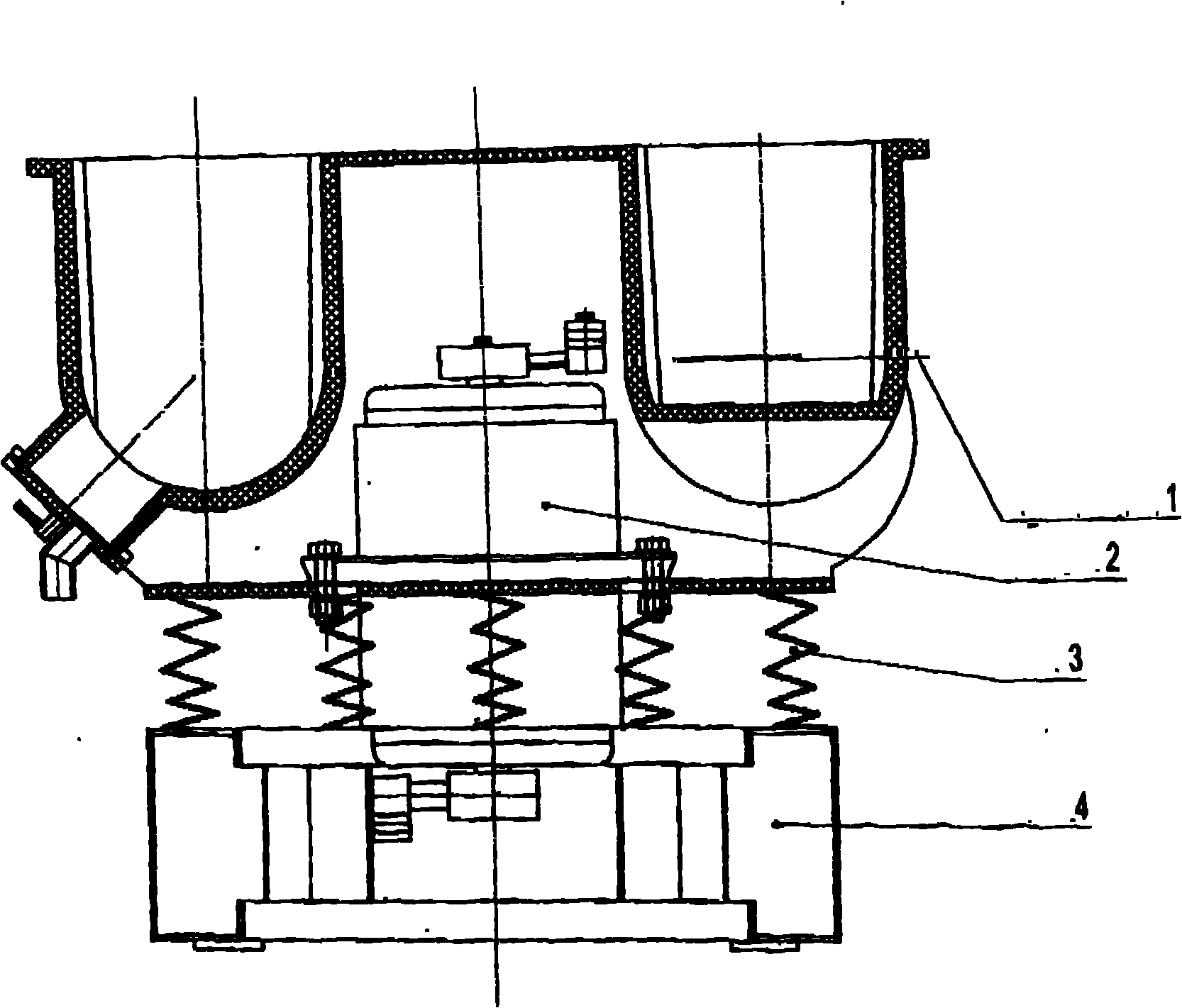

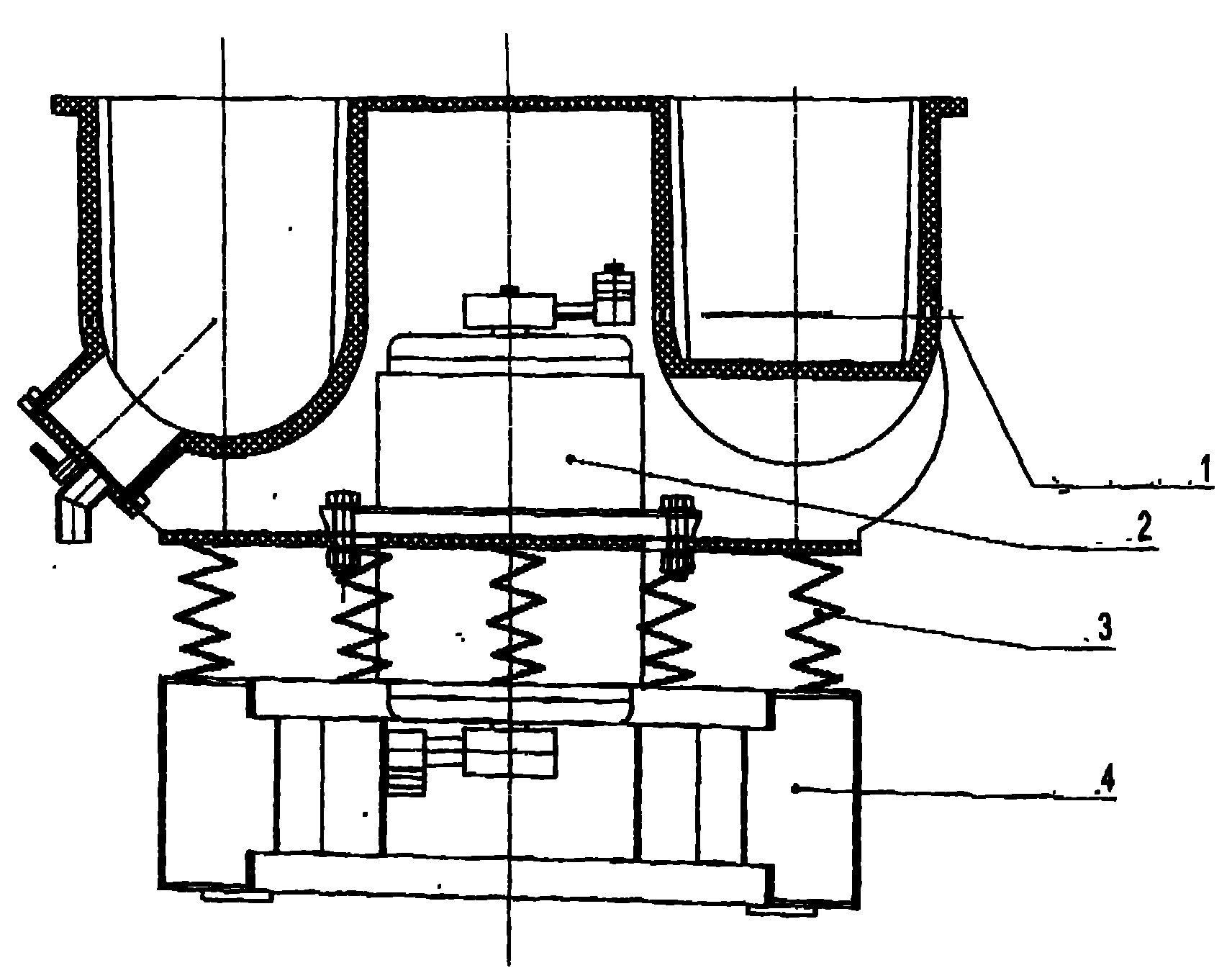

[0011] In this example, if figure 1 As shown, a new vibration finishing machine includes a base 4, a spring 3 between the base 4 and the connecting plate, a grinding tank 1 installed on the connecting plate, the grinding tank 1 is made of carbon fiber material, and the inner part of the grinding tank The surface is toothed. When the grinding tank 1 works, it is driven by the vibrating motor 2.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a novel vibrating finisher which comprises a pedestal, a spring positioned between the pedestal and a connecting plate, and a grinding groove arranged on the connecting plate. The novel vibrating finisher is characterized in that: the grinding groove is made of a carbon fiber material; and the inner surface of the grinding groove is tooth-shaped. The grinding groove of the novel vibrating finisher adopts the carbon fiber material, so the grinding grove has higher wear resistance than traditional polyurethane and 4 to 6 times higher abrasion resistance than polyurethane, prolongs the service life of the finishing machine, reduces resource waste, almost realizes zero replacement of wearing parts, creates economic benefits for enterprises, saves useable resources for the country, greatly improves the finishing time, finishes finishing processes of more products within a short period of time, greatly enhances a manufacturing schedule and creates self-evident economic benefits for enterprises.

Description

technical field [0001] The invention relates to a novel vibration finishing machine, which is suitable for polishing metal or non-metal parts. Background technique [0002] In the prior art, such as the polishing machines disclosed in the invention patent specifications of ZL99223505.7, ZL99225136.2, and ZL00210254.4, all are single-machine polishing metal or non-metallic parts to be processed. After finishing the work of polishing the parts, pour them into the sorting machine together with the parts and abrasives to separate the parts and abrasives, and then pour the abrasives into the working tank to polish the next batch of parts. The above-mentioned processing equipment is set up separately, and the entire processing procedure requires manual work, which is labor-intensive, time-consuming and laborious, and the processing efficiency is low. [0003] Another example is the ZL99250335.3 invention patent specification, which discloses a frequency-variable speed-regulating ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B24B31/06

Inventor 刘承绩

Owner 大连隆正光饰机制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com