Producing technique and producing die of syringe rubber stopper

A production process and syringe technology, which is applied in the field of medical devices, can solve problems such as the complexity of the syringe rubber stopper device, negative impact on the human body, and complex processing procedures, and achieve the effects of saving assembly time, easy operation, and simple processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

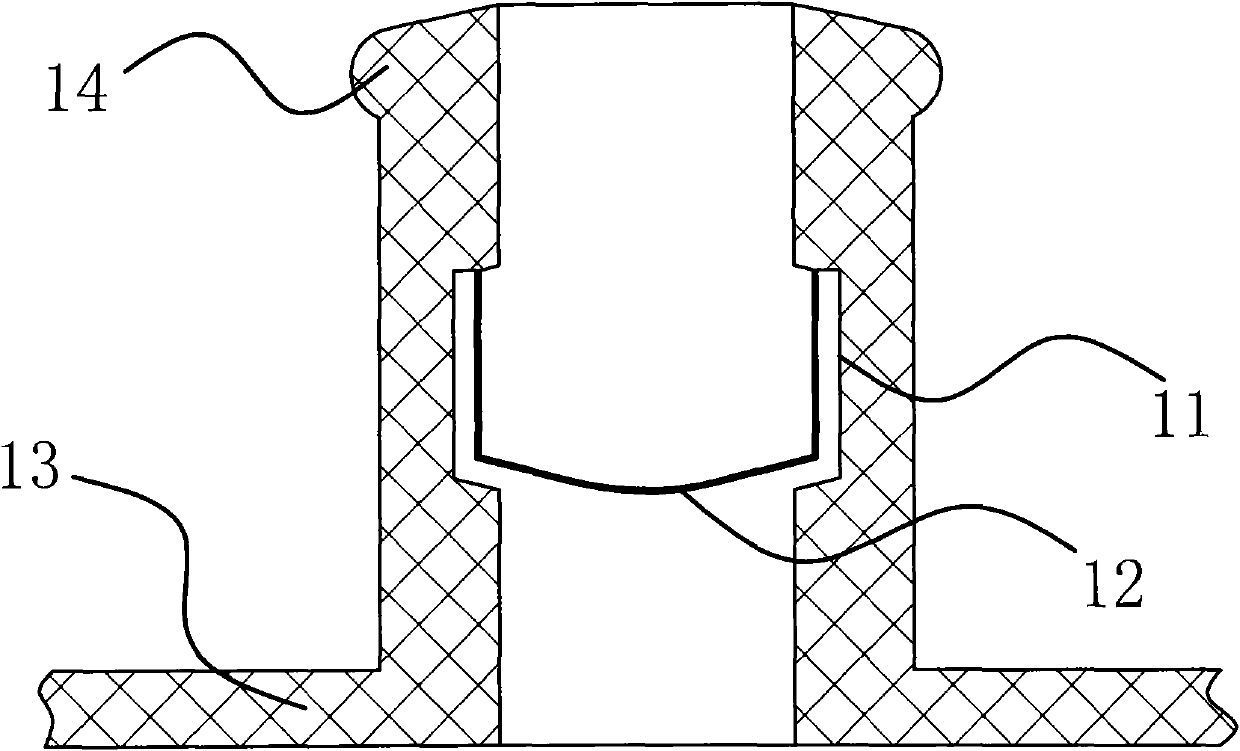

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

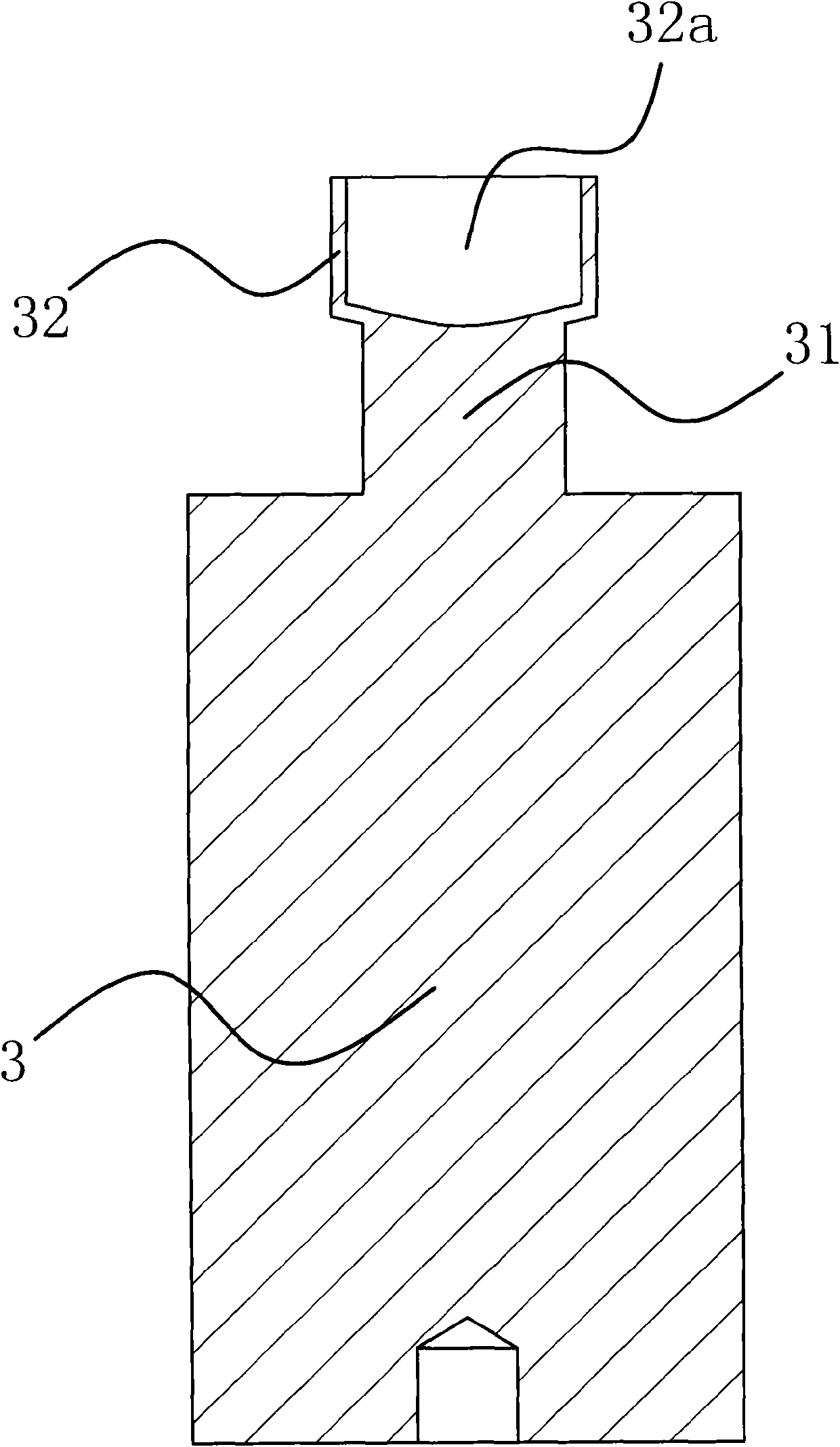

[0041]This syringe rubber stopper mould, comprises convex template 5 and female template 6, is fixed with several punches 3 by thread structure on convex template 5, is fixed with several concave molds 4 by thread structure on concave template 6, each punch 3 and the die 4 are distributed in an array, and the die 4 and the punch 3 can be fastened to each other. When the punch plate 5 and the die 6 are fastened, the punch 3 and the die 4 are arranged in one-to-one correspondence.

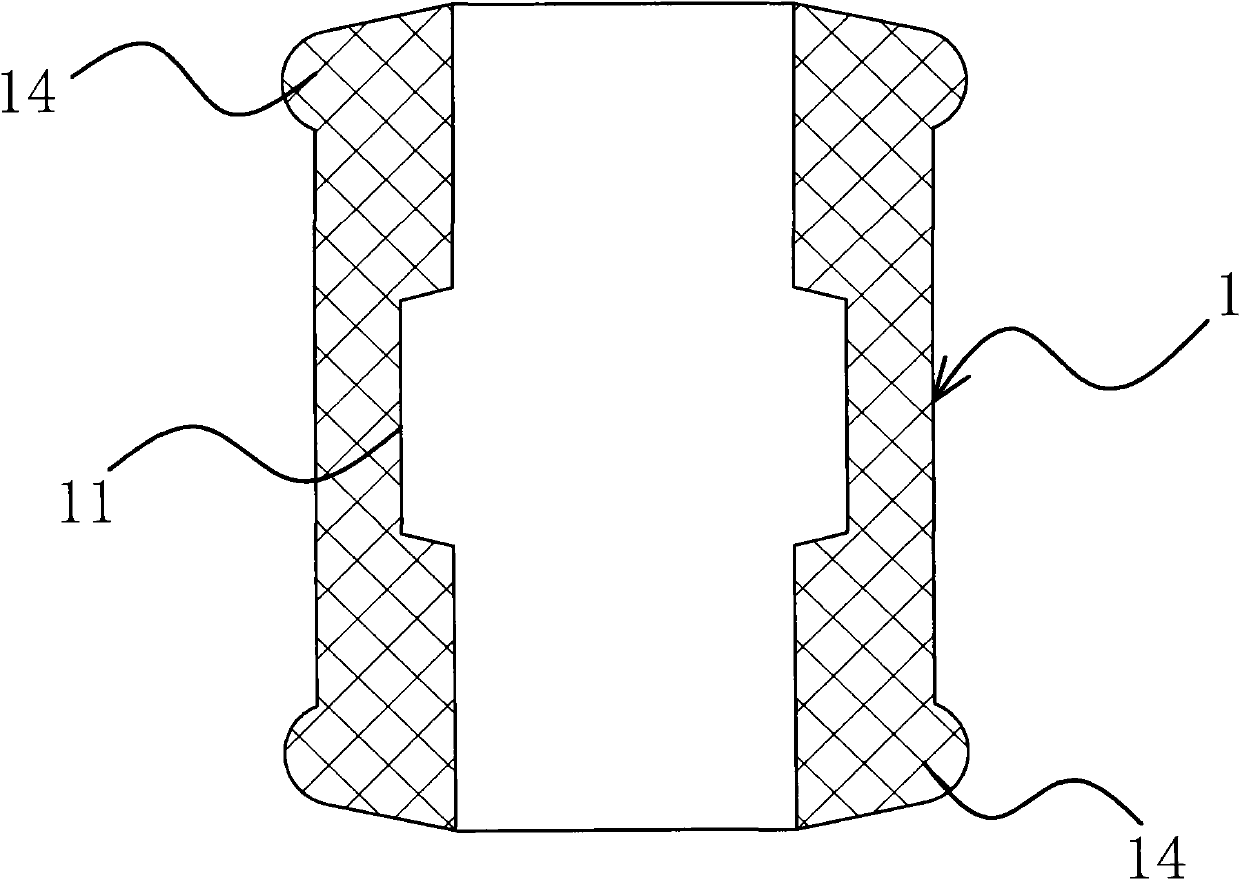

[0042] The die 4 has a cylindrical cavity 41, and the center of the bottom of the cylindrical cavity 41 has an axially protruding inner rod 42. The center of the punch 3 has an axially protruding insertion rod 31, and the end of the insertion rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com