Resilient item, more particularly drive belt, with a coating

A technology for coverings and products, applied in the direction of transmission belts, belts/chains/gears, belts, etc., can solve problems such as insufficient noise behavior, insufficient bending flexibility, molding problems, etc., and achieve the effect of improving wear protection and ensuring wear protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The invention will now be explained by means of an exemplary embodiment with reference to the schematic drawings.

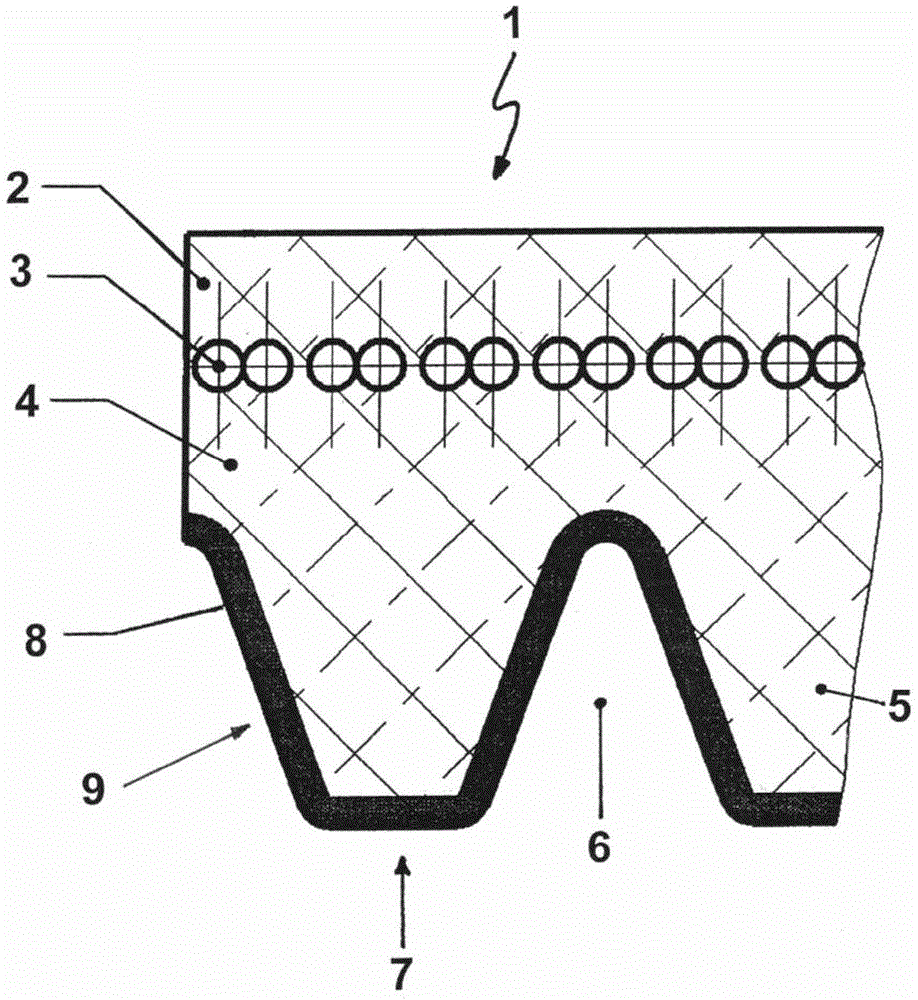

[0057] The only figure shows a drive belt 1, which is formed as a ribbed V-belt, with a cover layer 2 as the belt back, a reinforcing fabric layer and a substructure 4, the reinforcing fabric layer has a Tensile carriers 3 in the form of individual threads arranged running parallel in the longitudinal direction. The covering layer and the substructure constitute the elastomeric matrix based on a cured substance, for example based on EPDM. The substructure has a multi-wedged triangular structure consisting of wedges 5 and grooves 6 . The substructure here includes the force transmission region 9 .

[0058] The covering 8 (here only covering the force transmission region 9 and the wedge portion 7 ) consists only of a single-layer LLDPE foil. Here, the LLDPE foil is applied to the substructure mixture prior to packaging.

[0059] The tensile carrier 3 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com