Production process and application of stainless steel seamless tube

A production process and technology of seamless pipes, applied in the field of stainless steel, can solve the problems of poor stability of seamless pipes and cumbersome production processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

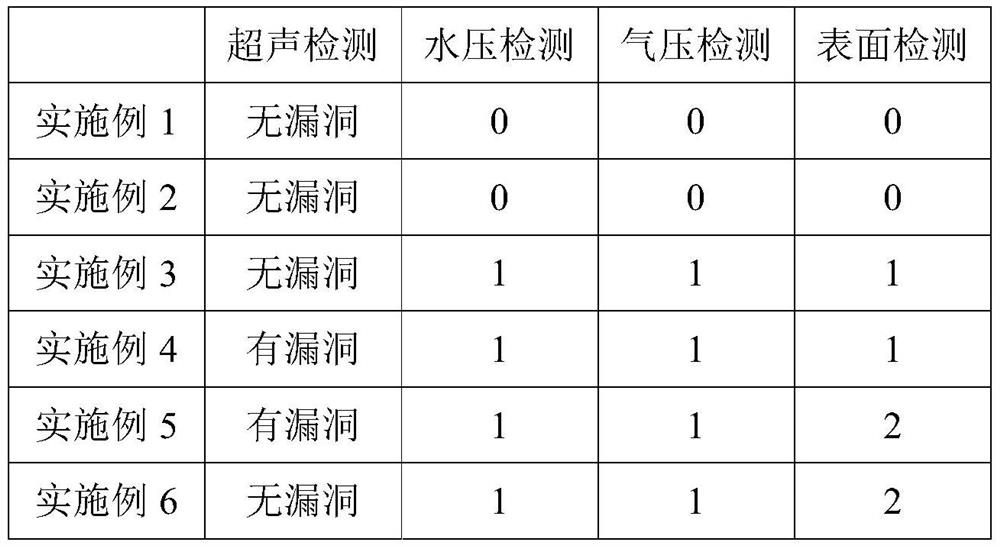

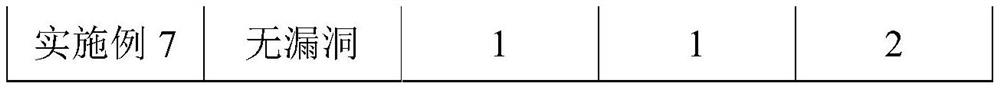

Examples

Embodiment 1

[0061]This embodiment provides a production process of stainless steel seamless tubes, and the specific steps include:

[0062]S1. Select seamless pipe blank, pickling, resulting in stainless steel seamless pipe;

[0063]S2. The outer circulation of stainless steel seamless pipe is performed;

[0064]S3. Cold rolling of stainless steel seamless pipe after foreign circular polishing;

[0065]S4. Stermers of stainless steel seamless pipe after cold rolling;

[0066]S5. It is vacuum brightened and irradiated with a stainless steel seamless pipe after degreasing.

[0067]S6. Stainless steel seamless pipe after vacuum brightening is straightened, cutting up;

[0068]S7. For straightening, the stainless steel seamless tube coarse material is performed in the inner circulation, resulting in a stainless steel seamless pipe finished product;

[0069]S8. Package the stainless steel seamless pipe finished product and warehouse.

[0070]The material of the seamless pipe billet is 316L, purchased from Shanghai Baigu Indus...

Embodiment 2

[0077]This embodiment provides a production process of stainless steel seamless tubes, and the specific steps include:

[0078]S1. Select seamless pipe blank, pickling, resulting in stainless steel seamless pipe;

[0079]S2. For stainless steel seamless pipe coarse material

[0080]S3. Cold rolling of stainless steel seamless pipe after foreign circular polishing;

[0081]S4. Stermers of stainless steel seamless pipe after cold rolling;

[0082]S5. It is vacuum brightened and irradiated with a stainless steel seamless pipe after degreasing.

[0083]S6. Stainless steel seamless pipe after vacuum brightening is straightened, cutting up;

[0084]S7. For straightening, the stainless steel seamless tube coarse material is performed in the inner circulation, resulting in a stainless steel seamless pipe finished product;

[0085]S8. Package the stainless steel seamless pipe finished product and warehouse.

[0086]The material of the seamless tube billet is 321, purchased from Shanghai Jongong Metal Products Co., Ltd...

Embodiment 3

[0093]This embodiment provides a production process of stainless steel seamless tubes, and the specific steps include:

[0094]S1. Select seamless pipe blank, pickling, resulting in stainless steel seamless pipe;

[0095]S2. For stainless steel seamless pipe coarse material

[0096]S3. Cold rolling of stainless steel seamless pipe after foreign circular polishing;

[0097]S4. Stermers of stainless steel seamless pipe after cold rolling;

[0098]S5. It is vacuum brightened and irradiated with a stainless steel seamless pipe after degreasing.

[0099]S6. Stainless steel seamless pipe after vacuum brightening is straightened, cutting up;

[0100]S7. For straightening, the stainless steel seamless tube coarse material is performed in the inner circulation, resulting in a stainless steel seamless pipe finished product;

[0101]S8. Package the stainless steel seamless pipe finished product and warehouse.

[0102]The material of the seamless pipe billet is an Inconel 600, purchased from Shanghai Kai Metallurgical Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com