Production process of motor arc-shaped magnetic shoe

A production process and arc-shaped technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as large product performance deviations, increased production costs, and strong temperature sensitivity. It is not easy to achieve product efficiency , reduce production costs and avoid quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] A production process of an arc-shaped magnetic tile for a motor, the production process for an arc-shaped magnetic tile for a motor comprises the following steps:

[0020] S1: Ball milling processing of raw materials for the production of arc-shaped magnetic tiles for motors;

[0021] S2: The raw material after ball milling is formed into the arc-shaped magnetic tile blank of the motor by wet pressing molding process;

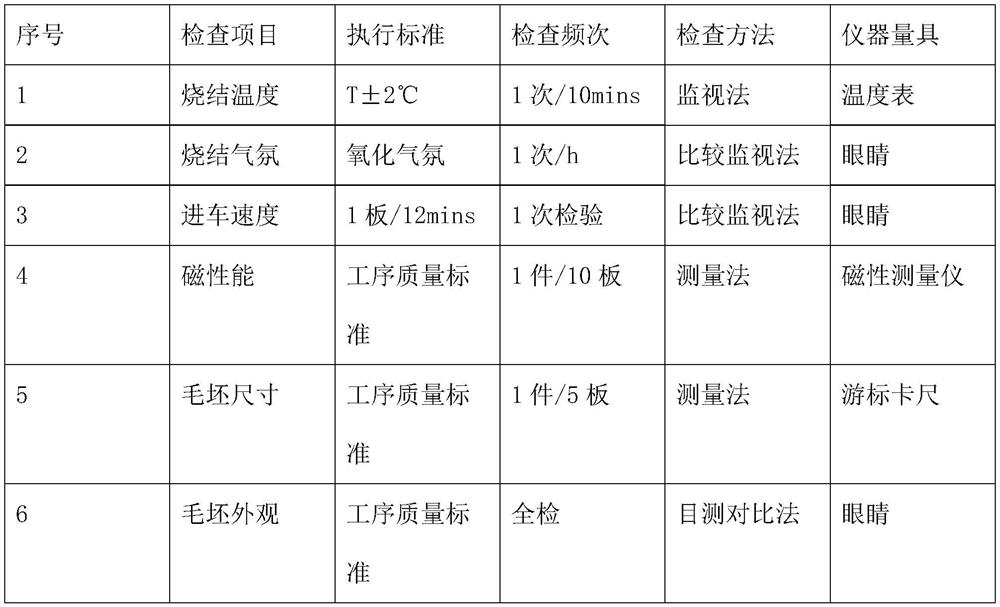

[0022] S3: Sintering operation of the formed motor arc-shaped magnetic tile blank;

[0023] S4: Grinding and quality inspection of the arc-shaped magnetic tile of the motor after sintering;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com