Kraft liner cardboard paper and manufacturing method thereof

A technology of liner board and its manufacturing method, which is applied in papermaking, textiles and papermaking, pulp raw material addition process, etc., can solve the problems of large consumption of wood resources, high dependence on wood resources, impact on ecological environment, etc., and meet the requirements of the process. Harshness, save timber resources, and protect the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

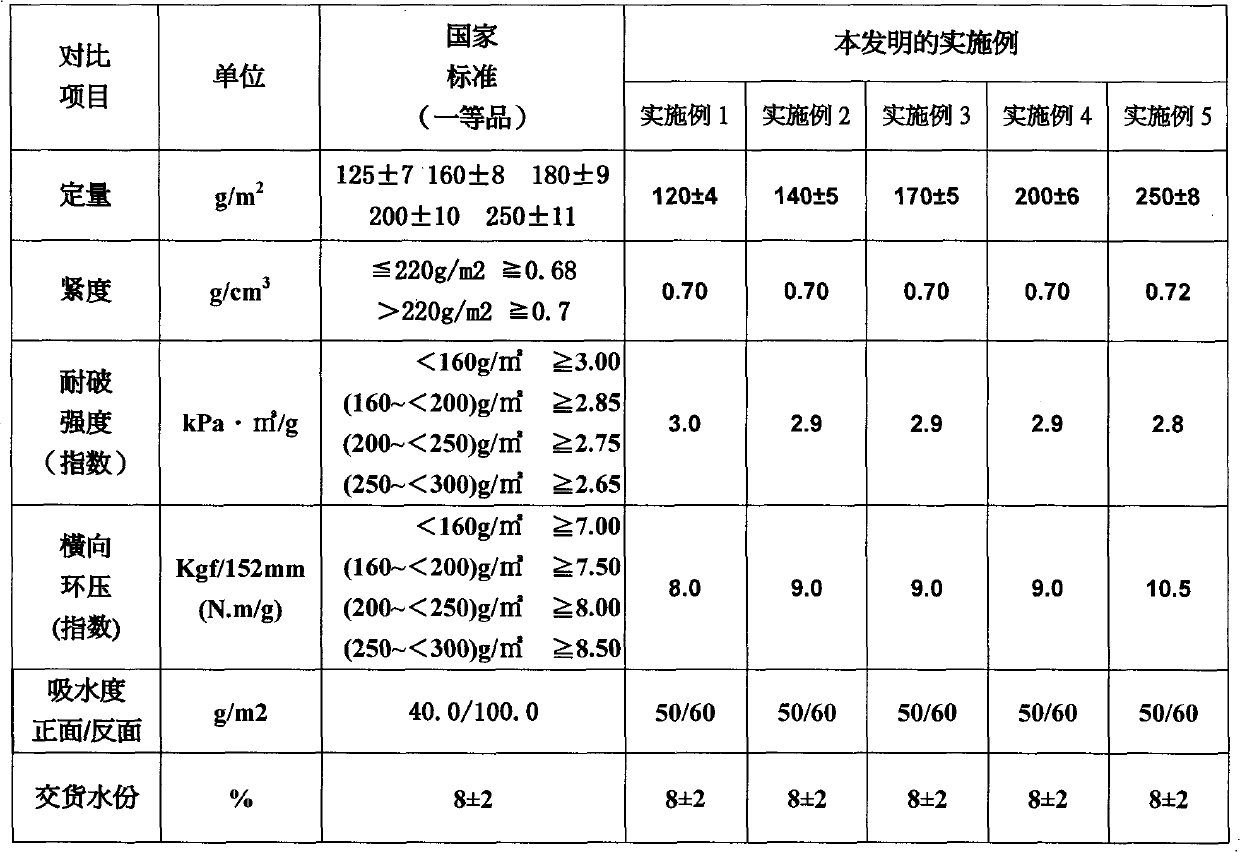

Examples

Embodiment 1

[0040] The first step is to prepare the surface pulp for papermaking (including four processes):

[0041] A). The raw material of flour pulp is prepared, and 3 parts of wood pulp are selected according to the weight ratio. Wherein, the wood pulp is 75 parts of IC-II Chongqing oxygen deluded pulp produced and sold by China Chongqing Liwen Paper Co., Ltd. 10 parts of Roll-A type reel wood pulp imported from the United States and 15 parts of Solomon wood pulp imported and sold by Qingdao Sanrunxing Import and Export Co., Ltd., Qingdao City, Shandong Province, China. Pulp, reel wood pulp and Solomon wood pulp are mixed to obtain wood pulp raw materials;

[0042] B). Prepare the first pulp of flour pulp, put the wood pulp raw material obtained by step A) into the pulper through the chain plate machine and pulverize it, so that the wood pulp is dissociated into fibers, and the volume ratio of wood pulp and water is 100:5, and the obtained initial batter;

[0043] C). High-concentr...

Embodiment 2

[0063] Only change the amount of wood pulp in the step A) of the first step to make papermaking surface layer pulp into 2 parts, and change the weight parts of Chongqing oxygen delignified pulp, reel wood pulp and Solomon wood pulp to form wood pulp Number is changed into 80 parts, 8 parts and 10 parts respectively, and the volume ratio of wood pulp and water in step B) is changed into 100: 4;

[0064] Only change the parts by weight of U.S. 11# waste paper, European waste paper and China's domestic high-grade carton paper into 40 parts, 25 parts and 30 parts in the step a) of the second step of making papermaking core bottom layer pulp, Change the volume ratio of raw material and water in step b) to 100:5;

[0065] Only change the amount of the starch-based reinforcing agent in step a') of the third step to 1g / m 2 , change the amount of surface glue starch and surface sizing agent in step c') to 6.2g / m respectively 2 Paper and 0.15g / m 2 Paper, all the other are with the de...

Embodiment 3

[0067] Only change the parts by weight of the wood pulp in the step A) of the step A) of the first step to make paper pulp, and change the weight of the Chongqing oxygen delignified pulp, reel wood pulp and Solomon wood pulp that constitute the wood pulp to 4 parts. Parts by weight are changed to 77 parts, 12 parts and 10 parts respectively, and the volume ratio of wood pulp and water in step B) is changed to 100:6;

[0068] Only change the parts by weight of U.S. 11# waste paper, European waste paper and China's domestic high-grade carton paper into 30 parts, 35 parts and 40 parts in the step a) of the second step of making papermaking core bottom pulp, Change the volume ratio of raw material and water in step b) to 100: 5.5;

[0069] Only change the amount of the starch-based reinforcing agent in the step a') of the third step to 1.25g / m 2 Paper, change the amount of surface glue starch and surface sizing agent in step c') to 5g / m respectively 2 Paper and 0.16g / m 2 Paper,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com