Suction nozzle with soft cavity throttling bodies inside

A body-saving and cavity-saving technology, which is applied in road cleaning, construction, cleaning methods, etc., can solve the problems of large particles of garbage that cannot reach the suspension speed, low air dispersion speed, and poor passability, so as to achieve significant energy saving and reduce waste. The effect of energy consumption and throttling energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

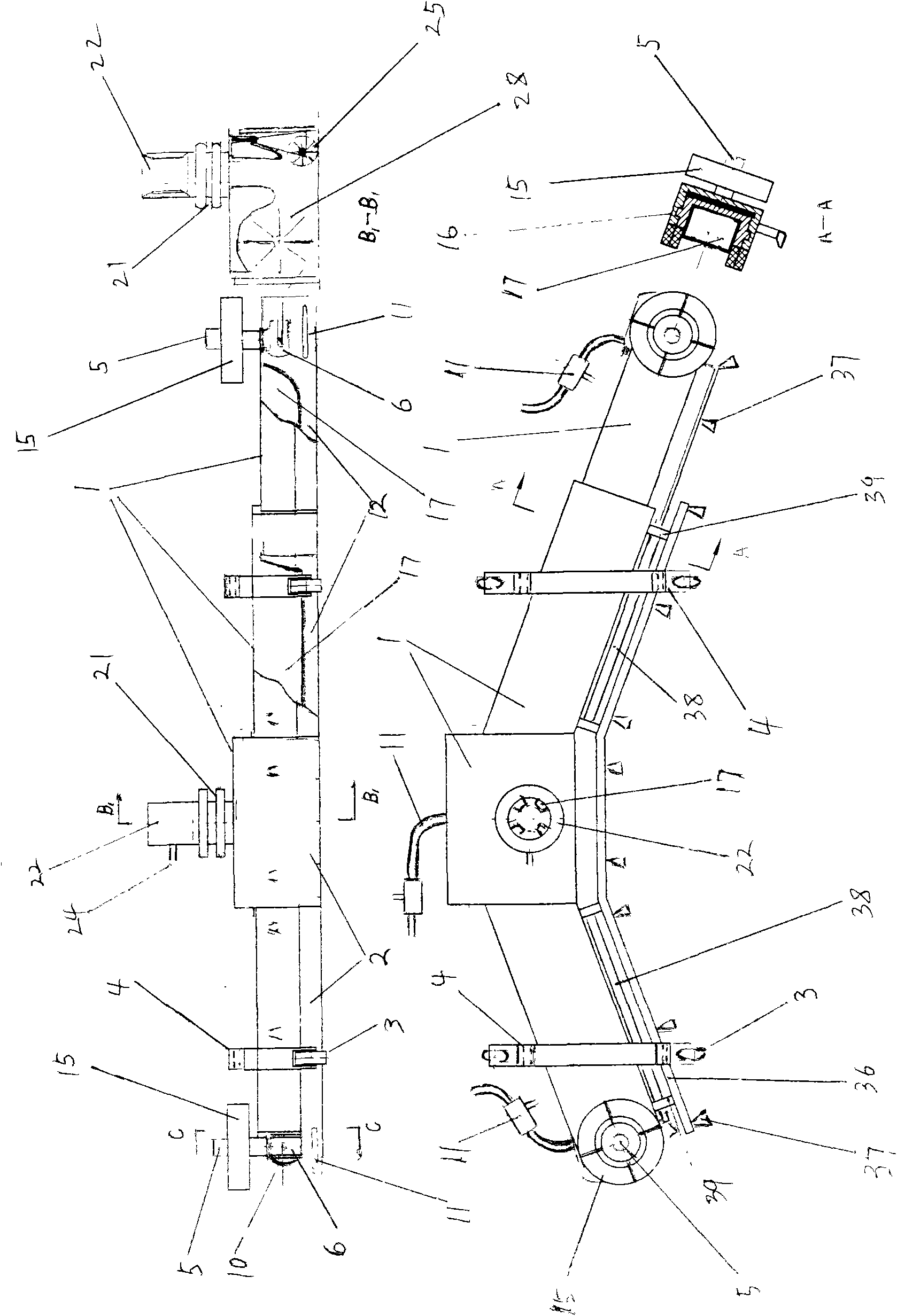

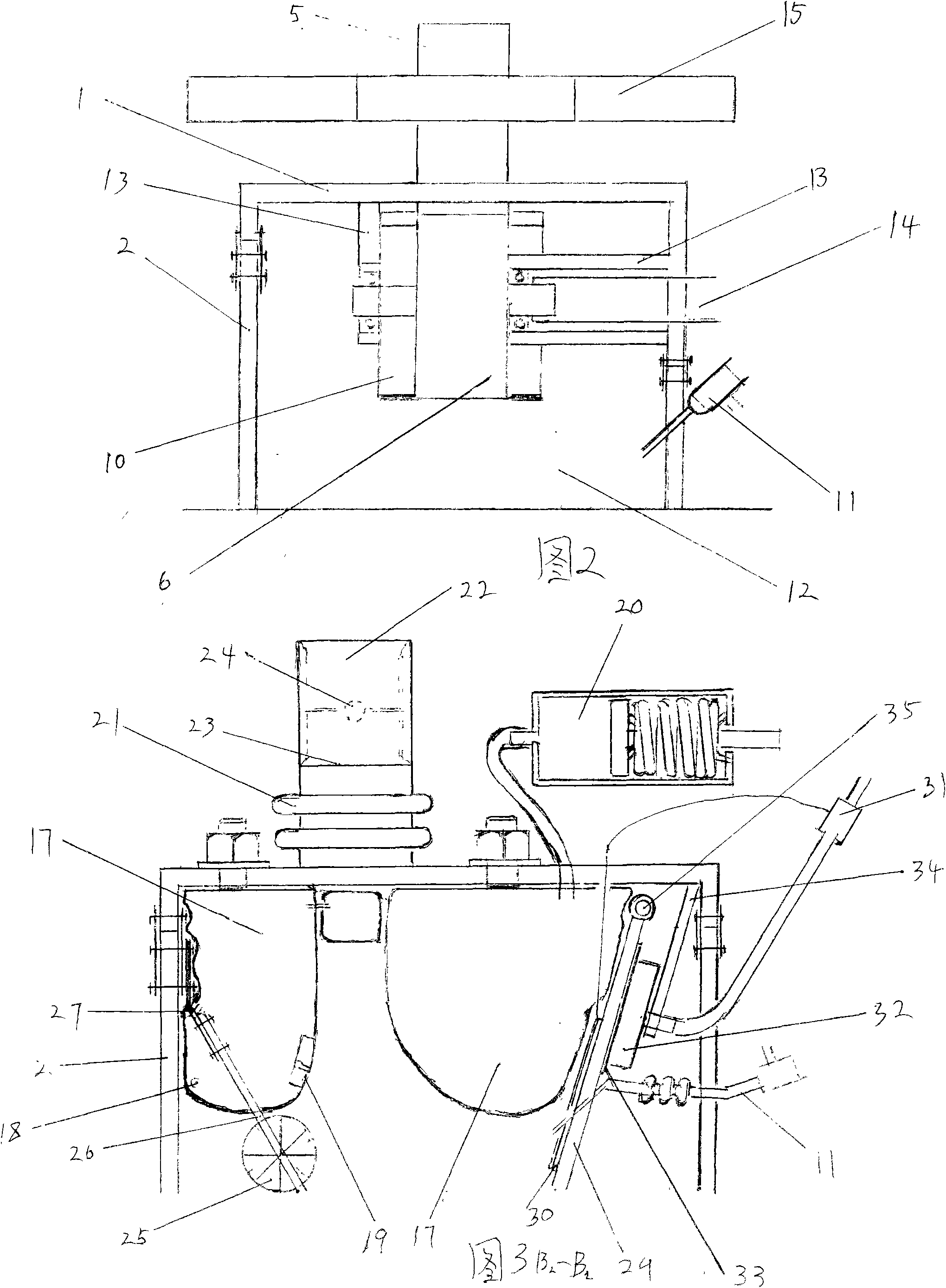

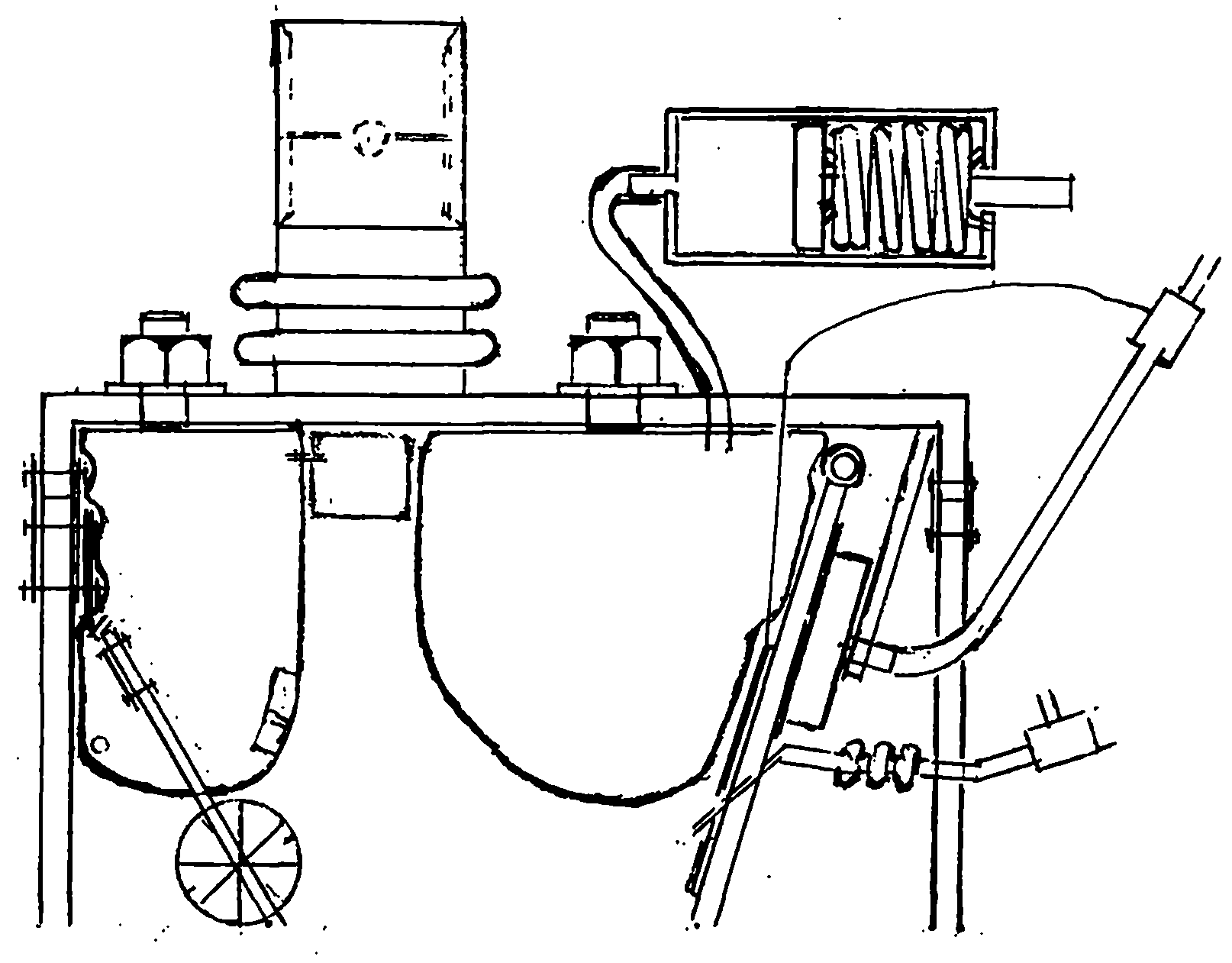

[0015] Below in conjunction with accompanying drawing, the specific mode of the suction nozzle with soft cavity throttling body is described in detail, as figure 1 , figure 2 , image 3 The suction nozzle is the main part of the suction nozzle in the middle section. The suction nozzles on the left and right sides are on both sides of the suction nozzle in the middle section. After telescopic sliding to 16, it is inclined forward and protrudes to the outside of the car body. The front and rear sealing rubber skirts 2, the airflow amplifier 22 supporting the walking wheels 3 and the annular nozzle in the middle area are connected to the upper cover 1 through the corrugated middle suction pipe 21, and the suction nozzles on the left and right sides have sealants on the front, rear and outer end faces of the upper cover 1 The left and right anti-collision guide wheels 15 fixed on the upper end of the skirt 2 and the outermost end upper cover 1 . The left, middle and right three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com