Simple steel frame plywood formwork and assembling method thereof

A technology of plywood and steel frame, which is applied in the field preparation and construction of formwork/formwork components, building components, etc., can solve the problems of increasing project cost and investment, large amount of construction process, large loss around the formwork, etc. The effect of reducing the amount of nails, good economic and social benefits, and improving the turnover rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

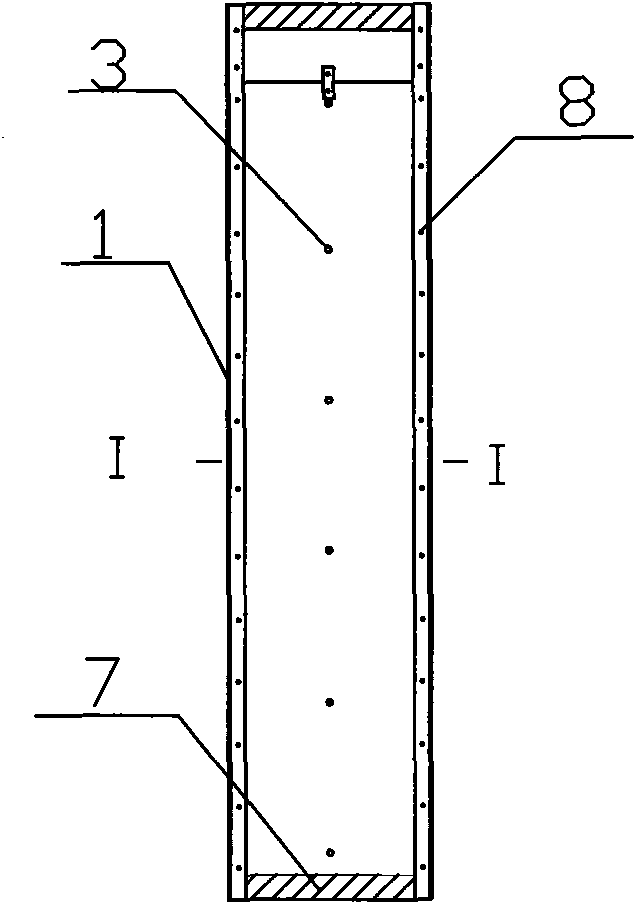

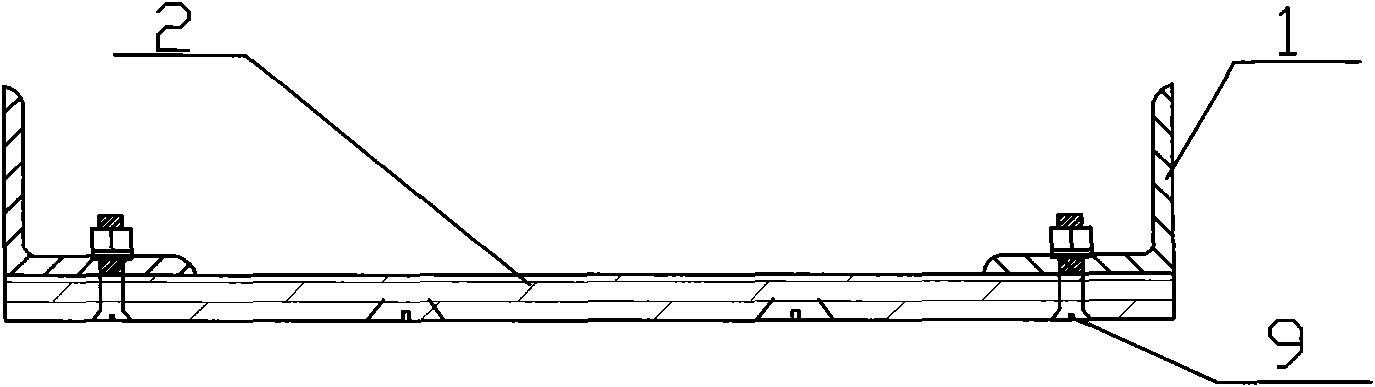

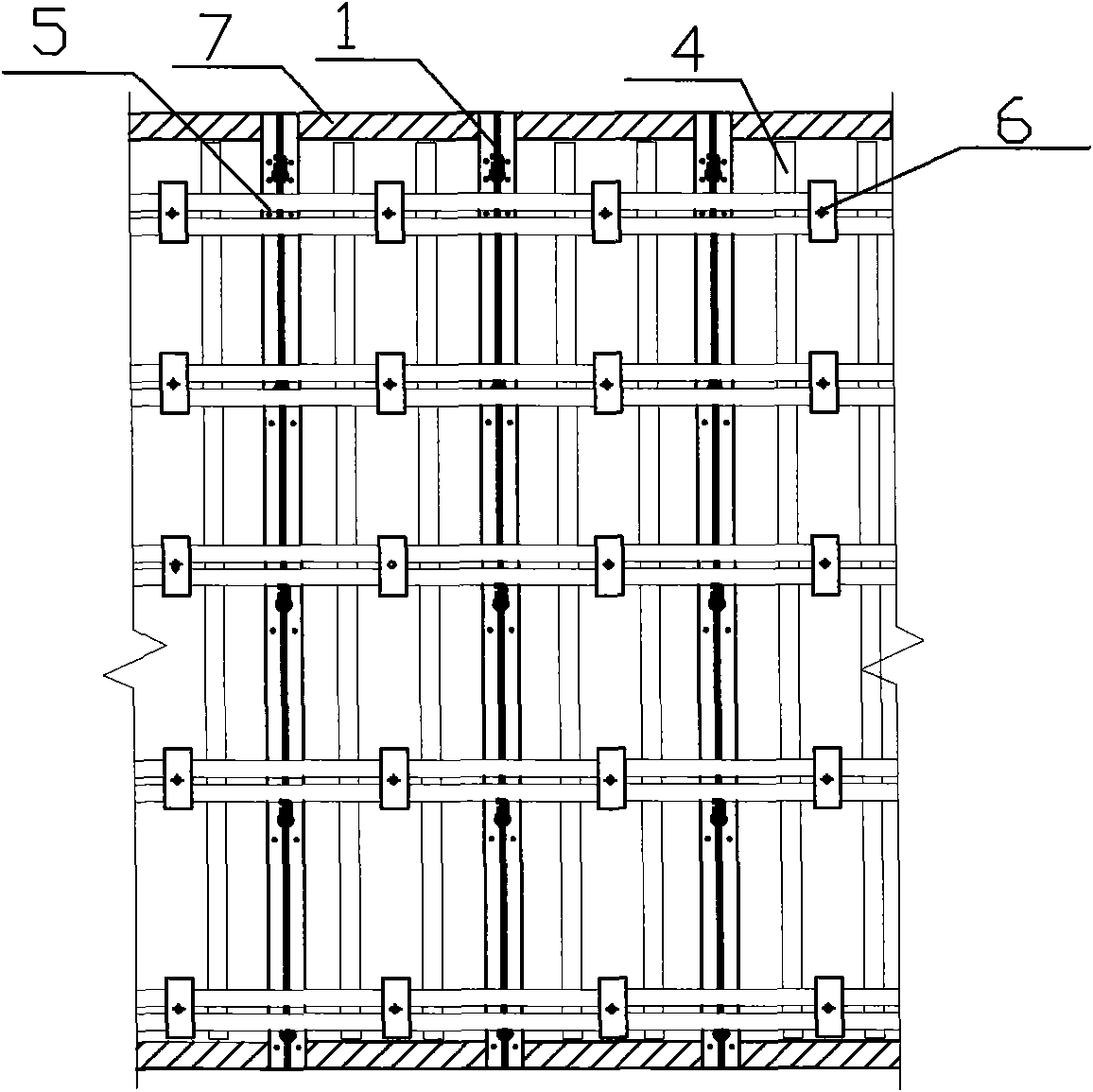

[0019] A simple steel frame plywood formwork, comprising a frame 1 and a panel 2 fixedly connected to the frame 1; the frame 1 is a hot-rolled angle steel frame, and the panel 2 is a plywood panel; The transverse rib 7 between the two frames 1 is provided with a vertical rib 8 between the top and the bottom outside the plywood panel on one frame 1; the steel frame is provided with a reserved hole, and the plywood panel is provided with a pull Bolt hole 3. The panel 2 is connected with the transverse rib and the vertical rib by countersunk head screws. Its frame 1 is connected with the panel 2 through self-tapping screws 9 .

[0020] The method for assembling the above-mentioned simple steel frame plywood template firstly determines the template type and configuration quantity according to the drawings, and configures the template according to the standard; then cuts the panel 2 into different sizes and specifications, and connects the panel 2 to the frame 1 with self-tapping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com