Control method and system thereof for biaxial gas-steam combined cycle unit

A combined cycle unit and control method technology, which is applied to steam engine installations, combined combustion mitigation, mechanical equipment, etc., can solve the problems of the automatic power generation AGC control module not being designed, not considering the primary frequency regulation capability of the steam turbine, and not considering the technical management regulations, etc. To achieve the effect of improving control quality, strong versatility and practicability, and improving the ability of load response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

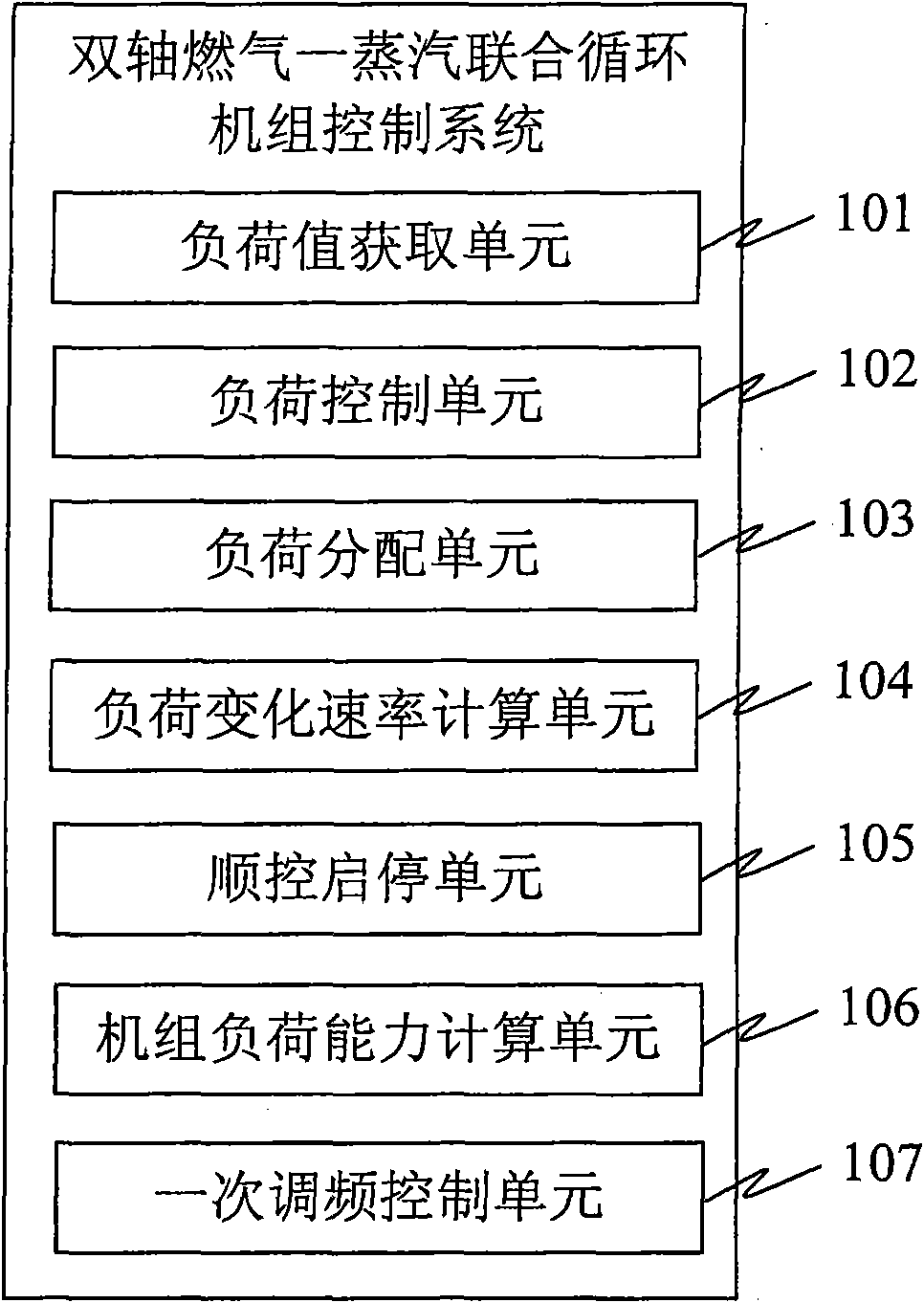

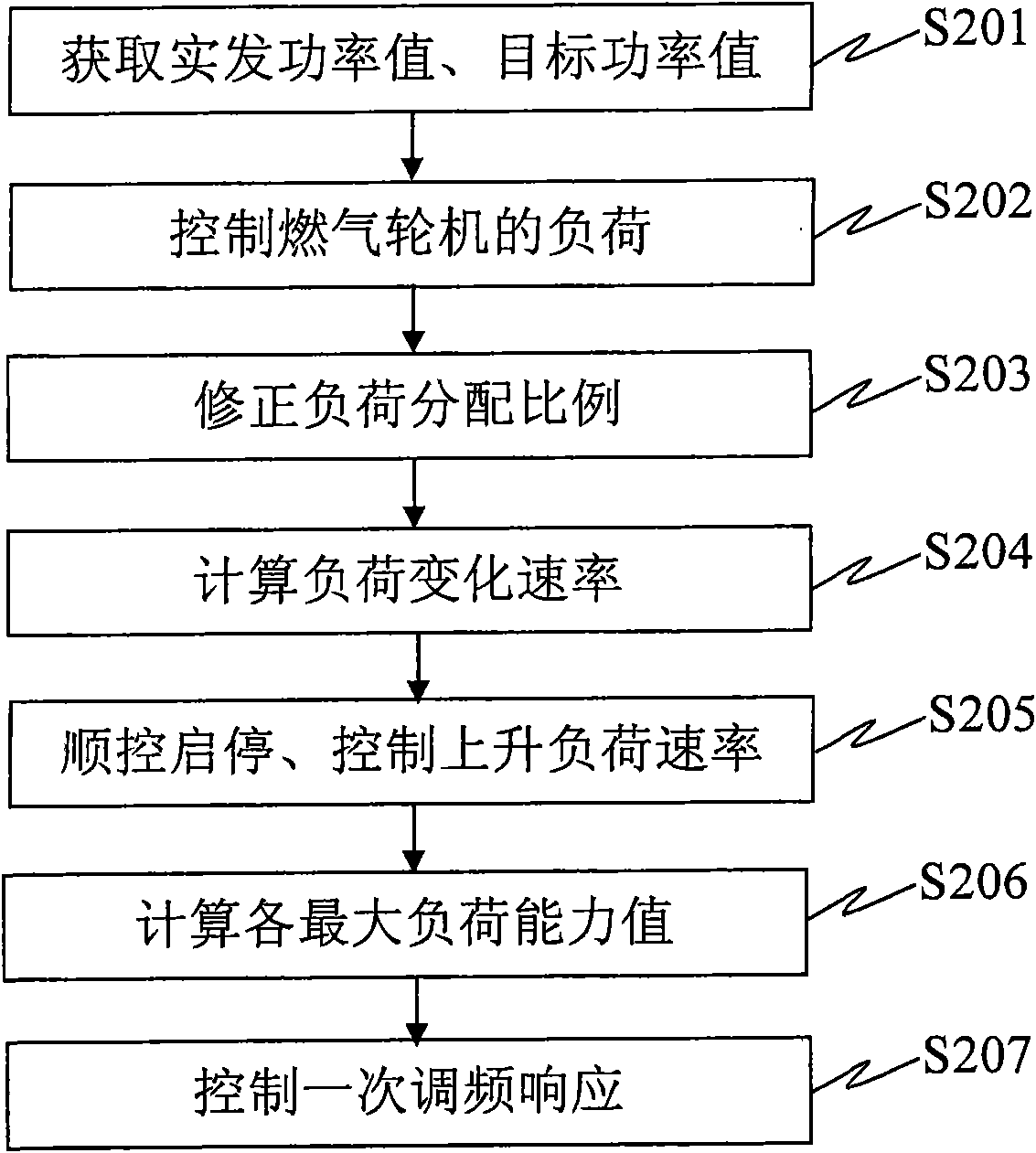

[0024] figure 1 Shown is the structural block diagram of the twin-shaft gas-steam combined cycle unit control system of Embodiment 1 of the present invention, as figure 1 As shown, the control system of the twin-shaft gas-steam combined cycle unit in Embodiment 1 of the present invention includes: a load value acquisition unit 101, which is used to acquire the actual power value and target power value of the twin-shaft gas-steam combined cycle unit The load control unit 102 is used to control the load of the gas turbine according to the deviation between the actual power value and the target load value, so that the actual power value is consistent with the target load value; the load distribution unit 103 is used to According to the actual operation of the twin-shaft gas-steam combined cycle unit, the load ratio of the gas turbine and the waste heat boiler-steam turbine is corrected; the load change rate calculation unit 104 is used to calculate the upper limit, lower limit, a...

Embodiment 2

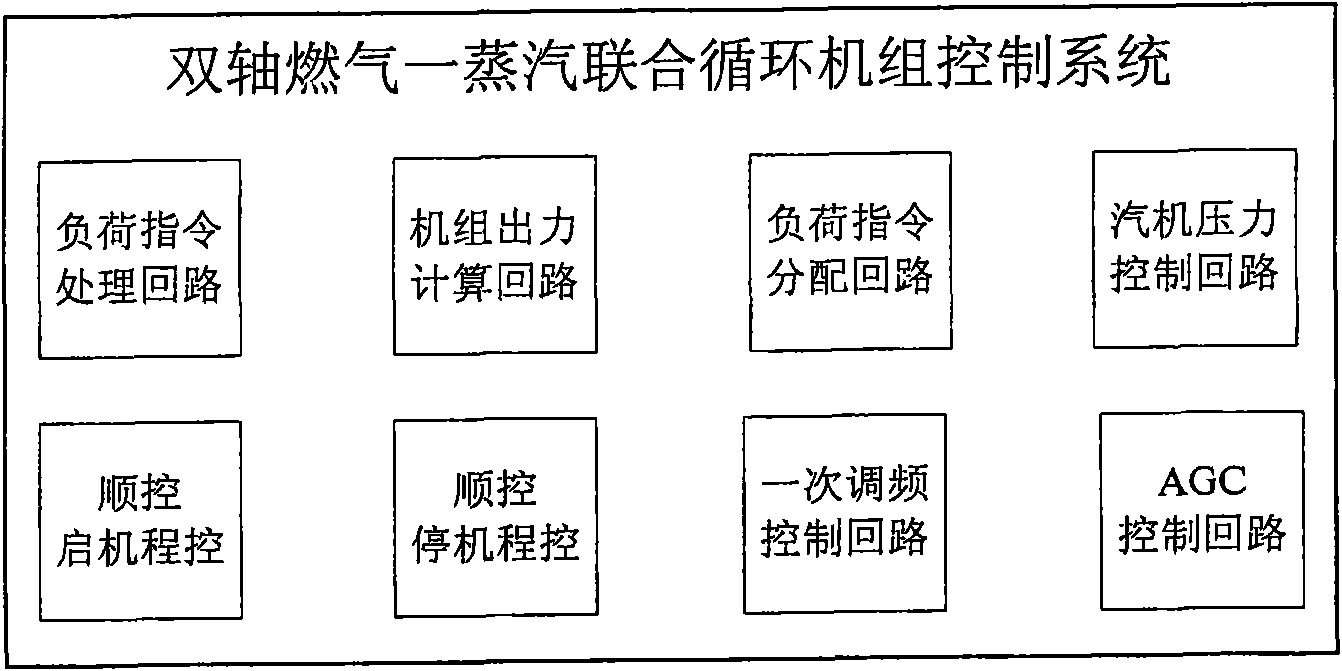

[0037] image 3Shown is a structural block diagram of the control system of the twin-shaft gas-steam combined cycle unit according to Embodiment 2 of the present invention. Such as image 3 As shown, the coordinated control technical solution of the twin-shaft gas-steam combined cycle unit control system in Embodiment 2 of the present invention mainly includes: the coordinated control function of the gas turbine generator set and the steam turbine generator set, automatic power generation (AGC) control loop, primary frequency modulation Control loop, sequential control start-stop function with breakpoint of combined cycle unit, etc.

[0038] Coordinated control function of gas turbine generator set and steam turbine generator set

[0039] The coordinated control module of the combined cycle unit is implemented on the side of the distributed control system (DCS), supplemented by the gas turbine control system (TCS), the steam turbine control system (DEH) and the necessary ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com