Method for monitoring pipeline corrosion

A pipeline and pipeline wall technology, applied in the field of sensing, can solve the problems of difficult implementation of detection and maintenance, complex and harsh environmental conditions, and inability to monitor submarine pipelines, so as to meet the needs of long-term stable monitoring and measure long-term stability and reliability. , the effect of improving the overall economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

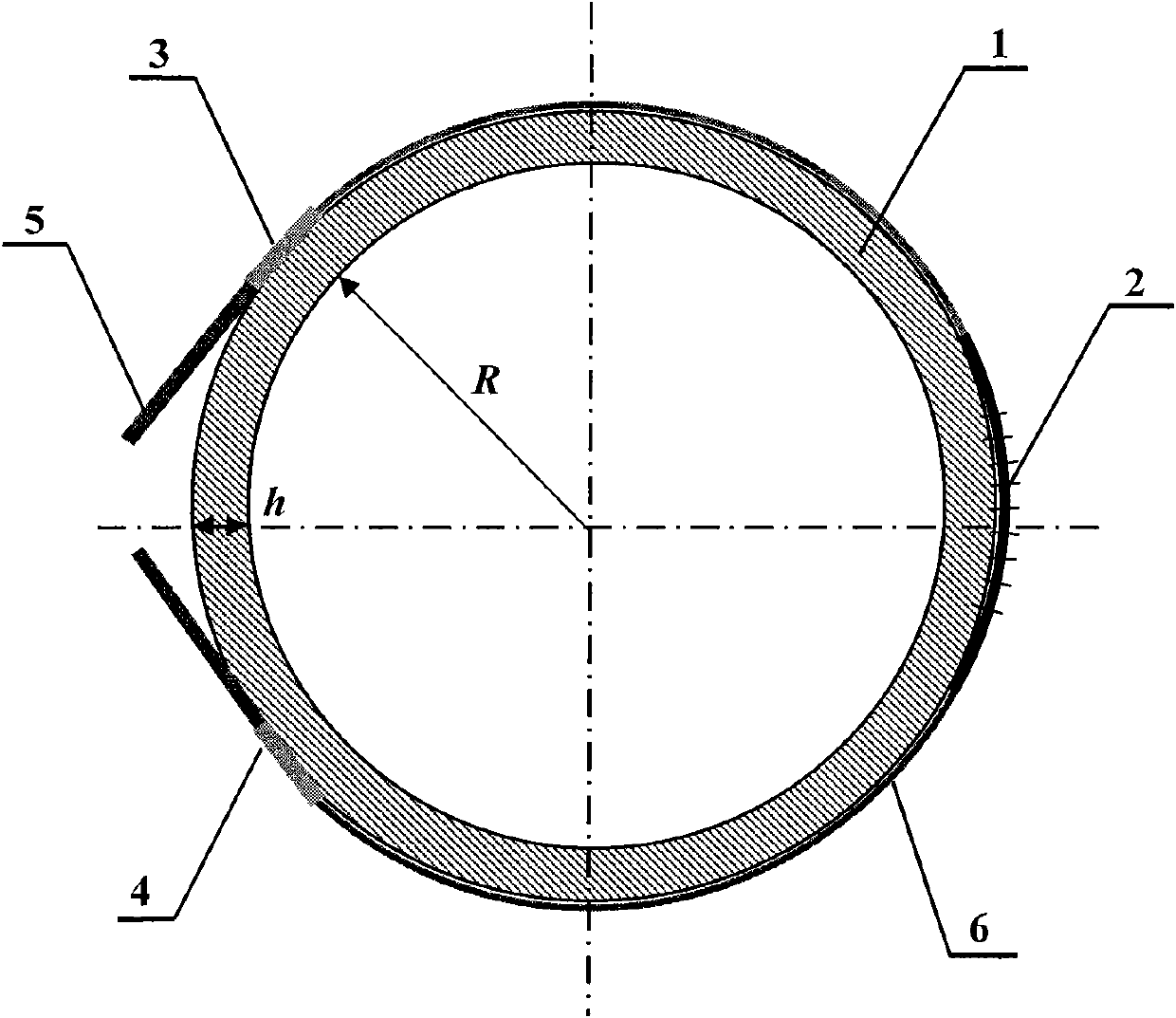

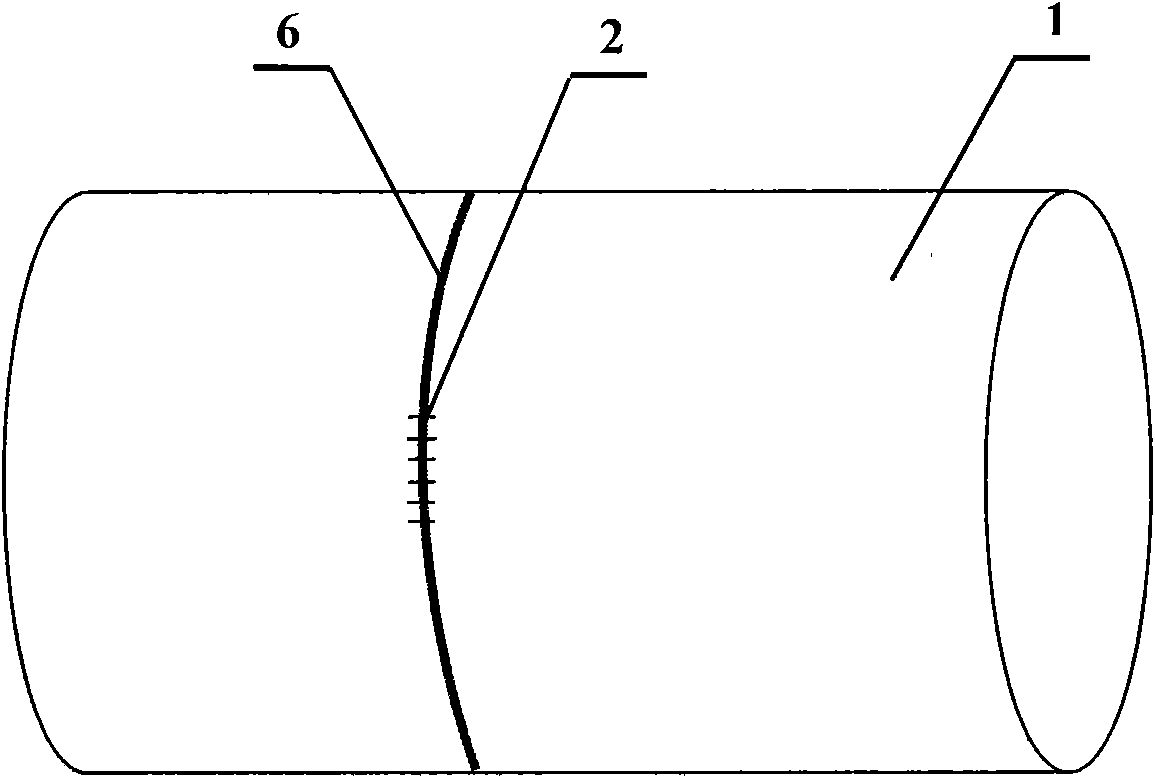

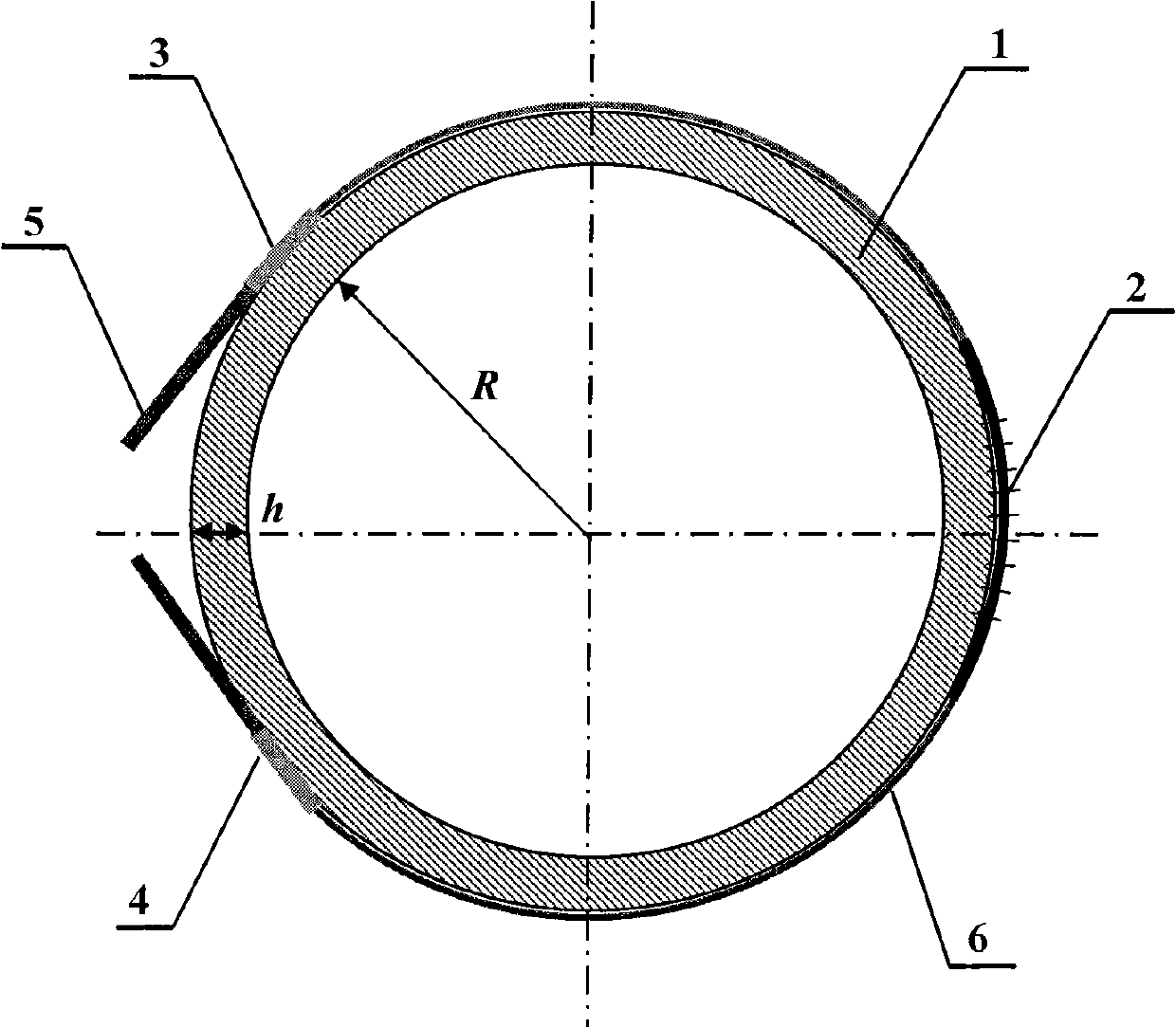

[0021] A schematic diagram of a method for monitoring pipeline corrosion proposed by the present invention is attached figure 1 And attached figure 2 shown. The specific process of fiber grating 2 installation method is:

[0022] Step 1: In order to ensure full contact between the fiber grating 2 and the outer wall of the pipe 1 and avoid measurement errors caused by strain transfer, first use a grinder to polish the outer wall surface of the pipe 1 to remove the paint layer, and then sand it with sandpaper to make the outer wall surface of the pipe 1 Flat and smooth. In order to prevent the impact of sanding dust, oil and other pollutants, use absorbent cotton balls dipped in absolute alcohol to scrub the sanding area.

[0023] Step 2: Paste the fiber bonding point A3 and the fiber bonding point B4 on the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com