Standard preparation method of optical spectrum

A preparation method and standard technology, applied in the preparation of test samples, material analysis by optical means, measurement devices, etc., can solve the problems of solution transfer, inability to carry out, main body interference, etc., to achieve a wide range of applications, small errors, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

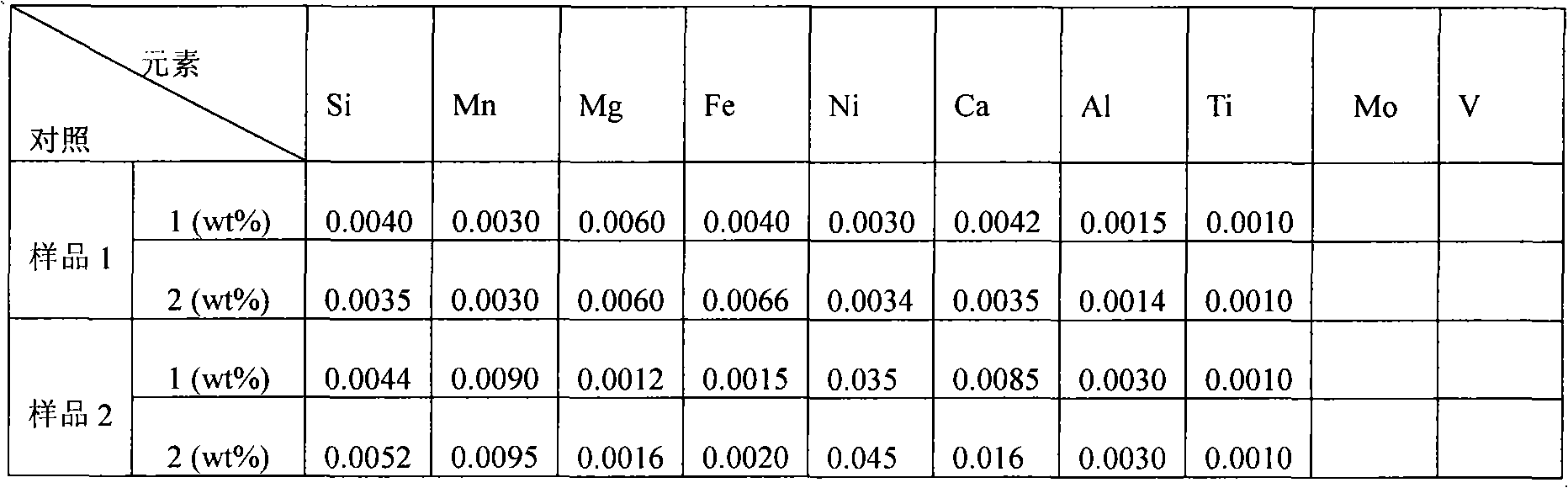

[0035] Using this method, a standard for spectroscopic analysis of W-Co-Cr alloy powder was prepared for Xianglu Company.

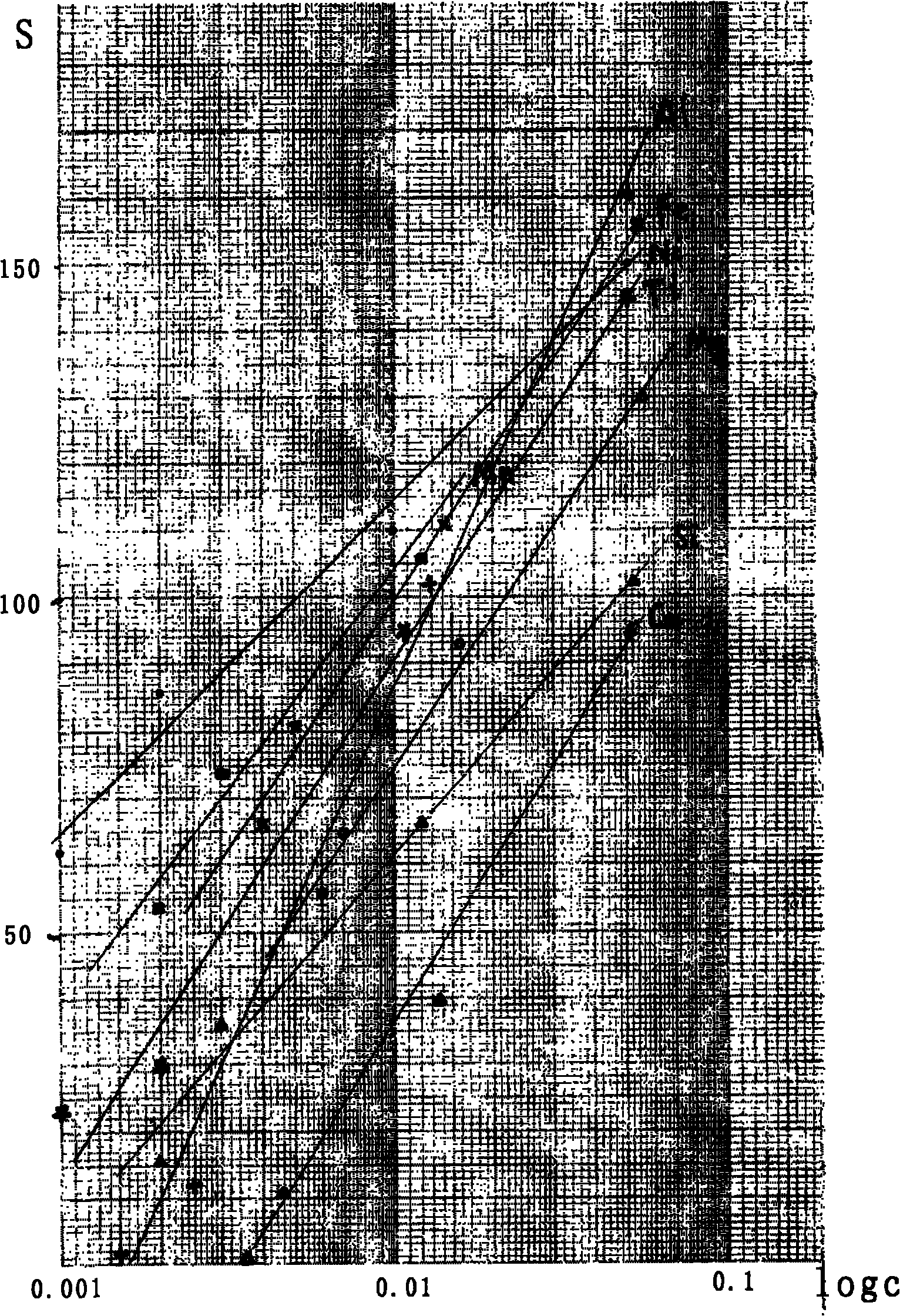

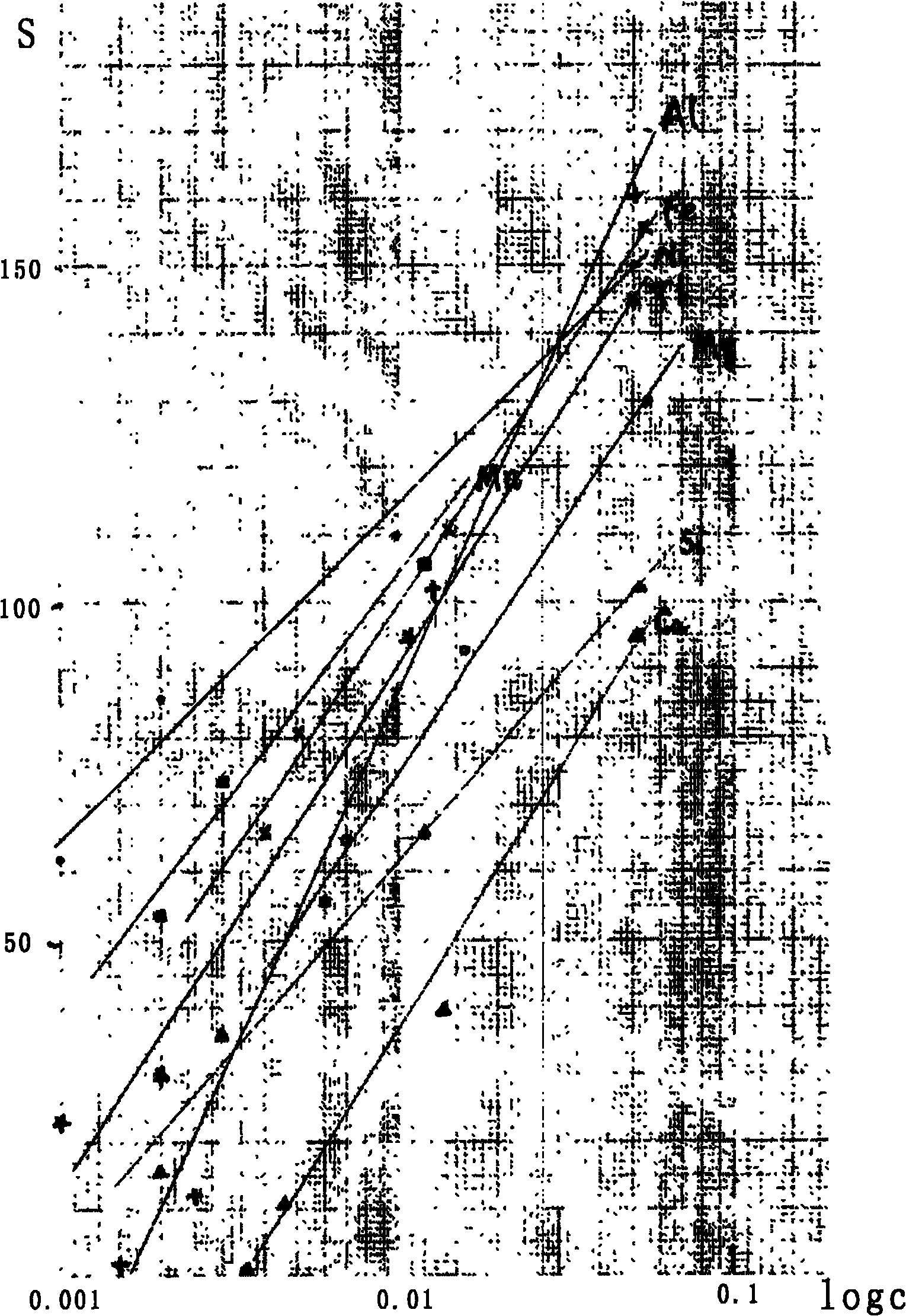

[0036] First, determine the target metal impurity elements to be measured for W-Co-Cr spectral analysis as Si, Mn, Mg, Fe, Ni, Ca, Al, Ti, Mo, and V; then use pure carbon powder as the matrix to transform pure carbon The corresponding oxides of Si, Mn, Mg, Fe, Ni, Ca, Al, Ti, Mo and V are added to the powder to prepare a carbon standard. Calculate the metal impurity elements contained in the carbon standard, and prepare 1wt% (per The main standard point of the content of a metal impurity element) is then diluted with pure carbon powder to 0.05wt%, 0.01wt%, 0.005wt%, 0.001wt% (the content of each metal impurity element) to obtain a Series carbon standard.

[0037] First, weigh 4 parts each of 500mg alloy powder, and mix them with pure carbon powder and carbon standard with impurity content of 0.001wt%, 0.01wt%, 0.05wt%, respectively, and mix them evenly; take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com