Battery pole piece and battery including same

A battery pole piece, battery technology, applied in secondary batteries, active material electrodes, circuits, etc., can solve the problem of battery capacity, life, high-rate discharge performance and safety performance reduction, non-uniform electron current carrying capacity, and falling off area. Large and other problems, to achieve the effect of being conducive to high current charging and discharging, not easy to side reactions, and easy to infiltrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the preparation method of the battery, except that the pole core is prepared according to the method provided by the present invention, other steps are well known to those skilled in the art.

[0039] A further description will be given below for each pole piece of the laminated type according to the present invention in conjunction with the accompanying drawings.

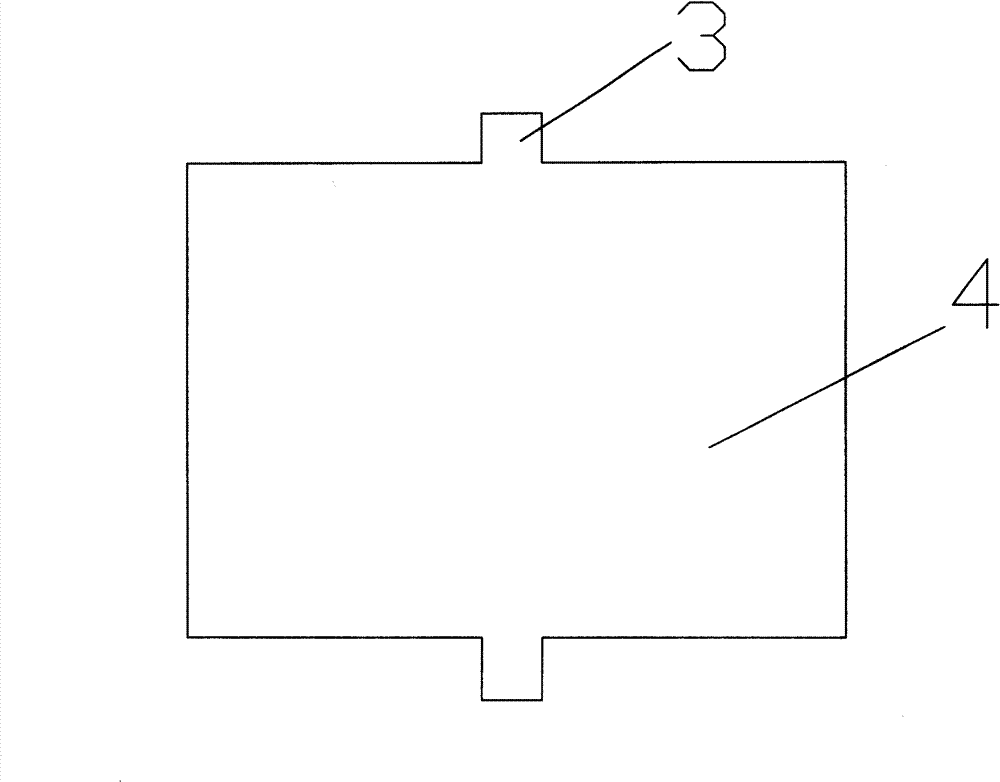

[0040] as attached figure 1 It is a schematic structural diagram of each pole piece of a conventional laminated battery, and tabs 2 are led out from both ends of each pole piece 4 .

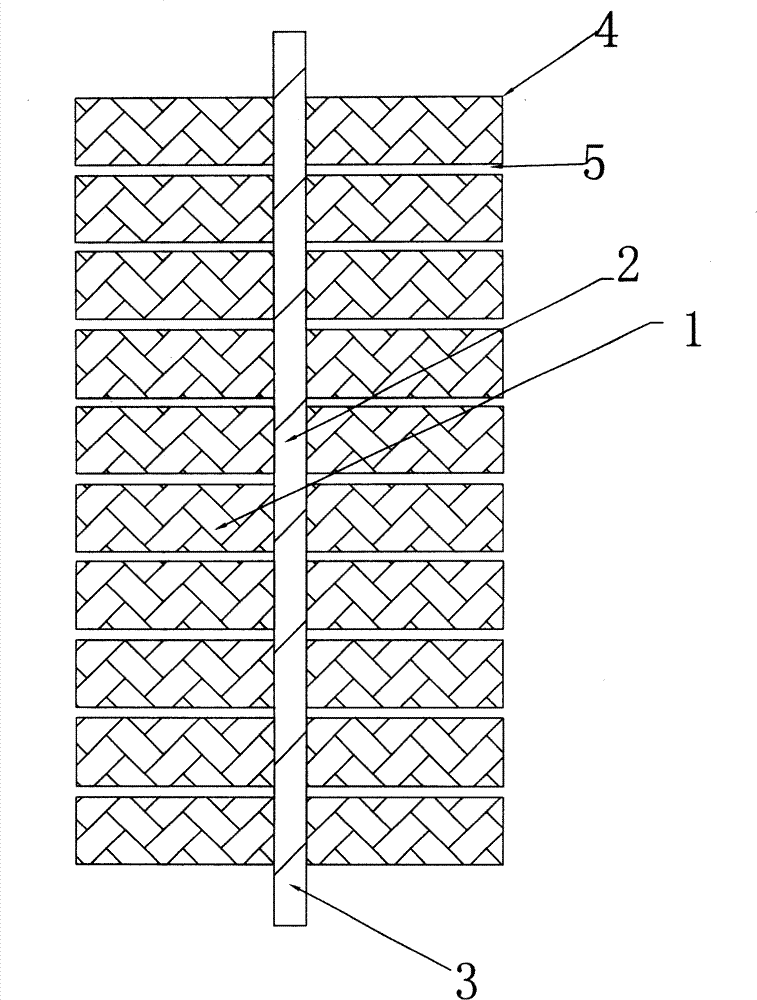

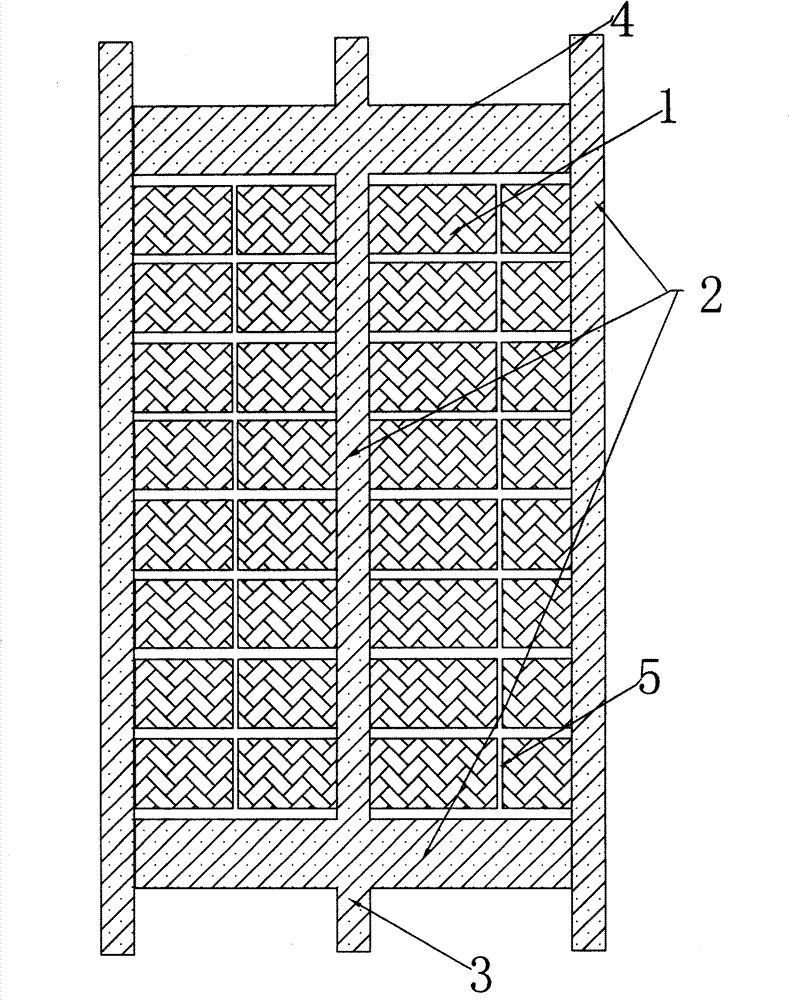

[0041] as attached figure 2 , attached image 3 It is a structural schematic diagram of two preferred embodiments of the present invention. The battery pole core of the present invention is a laminated pole core, and each pole piece 4 of the pole core includes a current collection part 2 and a plurality of mutually spaced The small pole pieces 1, the small pole pieces 1 are connected to each other through the current col...

Embodiment 1

[0044] (1) Preparation of positive electrode sheet

[0045] The cathode active material LiCoO 2 , conductive agent acetylene black, and binder PVDF according to the ratio of 9:1:1, add an appropriate amount of NMP and mix uniformly to form a slurry, and then evenly coat it on an aluminum foil with a thickness of 0.02 mm, dry and press Slice, cut. The total length of each pole piece is 118.5 to 123 mm, the width is 55 mm, and the thickness is 0.130 mm. Scrape off the material of the pole piece with some tabs to obtain a current collector with a length of 15 mm and a width of 5 mm. The main body of the pole piece dressing is cut into 10 small pole pieces, the length of the small pole piece is 25 mm, the width is 9 mm, and the interval between the small pieces is 0.3 to 1 mm. The whole pole piece is as follows: figure 2 shown. Fold the pole piece in half in the direction of diaphragm extension and seal it by welding. The diaphragm at both ends of the spot-welded lug is left u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com