Self-driven plug-in type centrifugal seeding device

A plug-in, seeder technology, which is applied in the field of self-driven plug-in centrifugal seeders, can solve the problems of unsatisfactory sowing quality, reduced operation reliability, and low production efficiency, so as to improve the quality of sowing operations, and the operation is simple, convenient and economical. time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail:

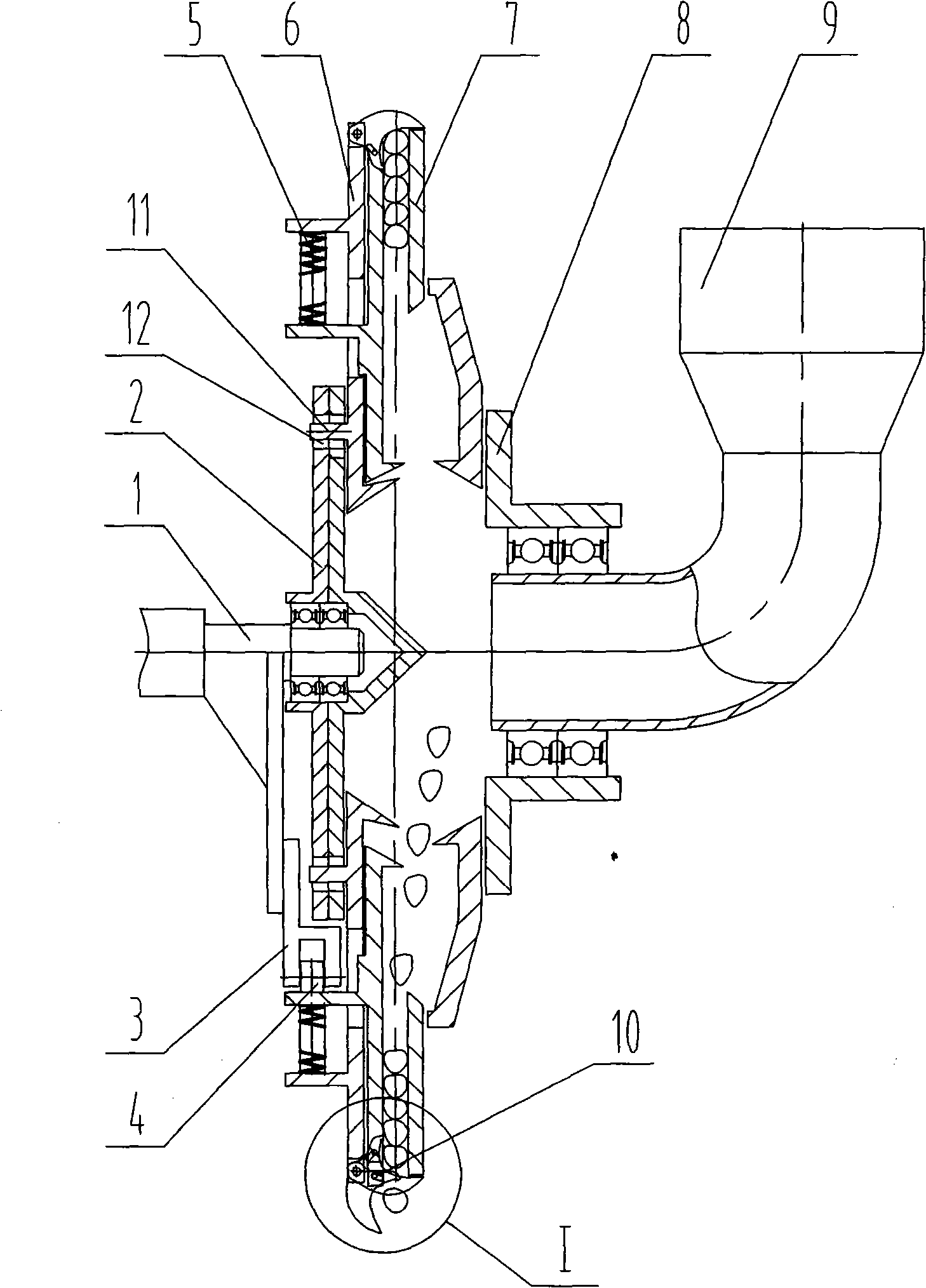

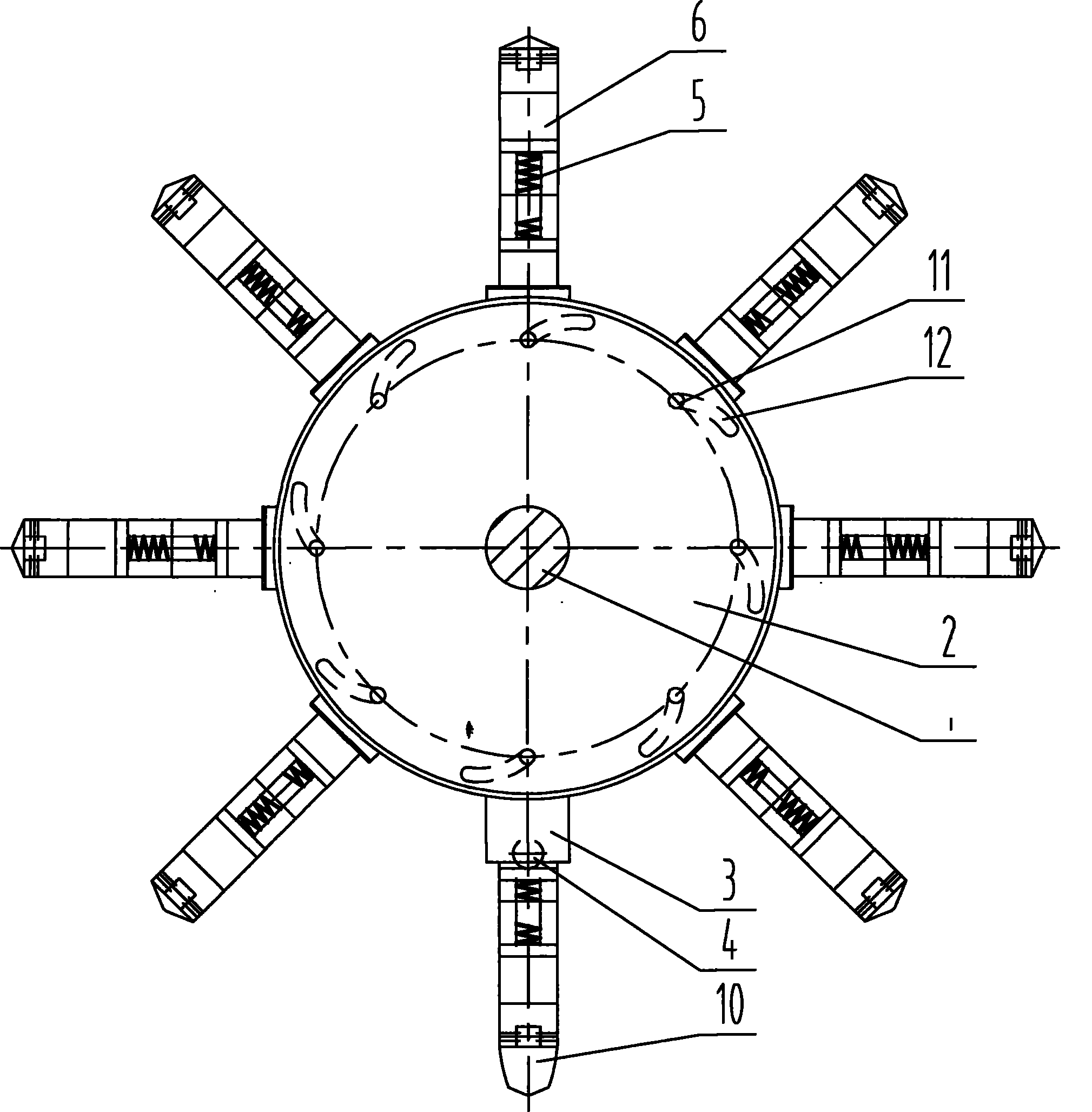

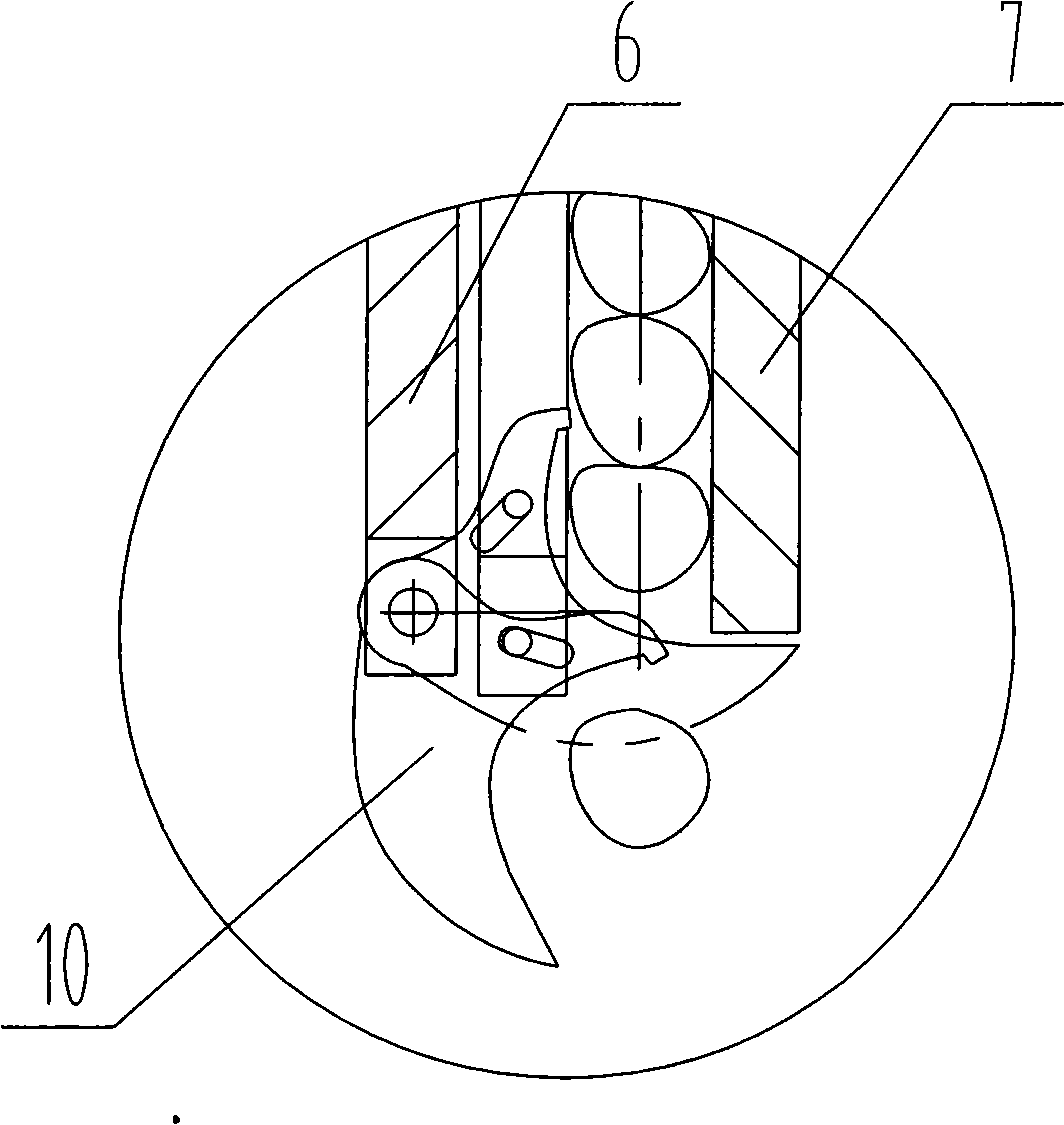

[0015] The structure of the self-driven plug-in centrifugal seeder of the present invention is as follows: figure 1 As shown, it consists of a support shaft 1, a disc 2, a cam bracket 3, a cam 4, a return spring 5, a seeding body 6, a telescopic seeding tube 7, a rotary housing 8, a seeding tube 9, a seeding spoon 10, Locating pin 11, arc-shaped locating hole 12 form. The support shaft 1 is fixed horizontally on the seeding frame, and the cam bracket 3 is vertically and rigidly fixed directly below the support shaft 1, and the cam 4 is horizontally supported and installed on the outer end of the cam bracket 3; the seed filling tube 9 is designed as a 90° arc The shape of the curved pipe, the seed-filling tube 9 is fixed on the sowing frame, and the center line of the horizontal section of the seed-filling tube 9 is coaxial with the support shaft 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com