Method for preparing antioxidative active extractive of sweet potato leaves

A technology of antioxidant activity and sweet potato leaves, applied in the direction of medical preparations containing active ingredients, anti-toxins, drug combinations, etc., can solve the problems of unreasonable utilization of stems, leaves and vines, pollution of the environment, waste of resources, etc., and achieve significant The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

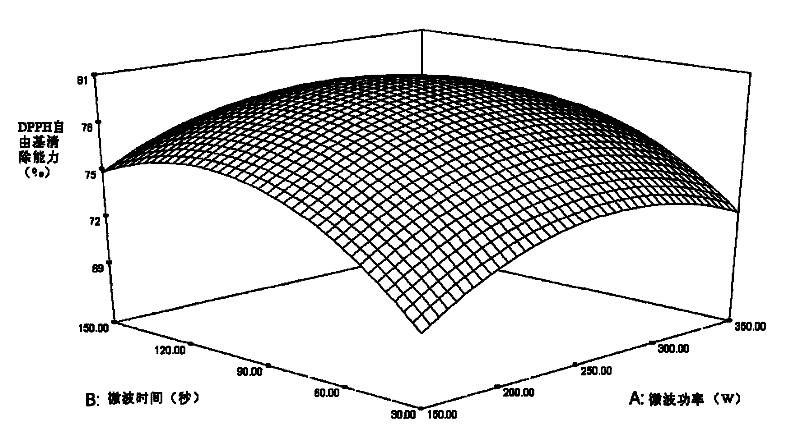

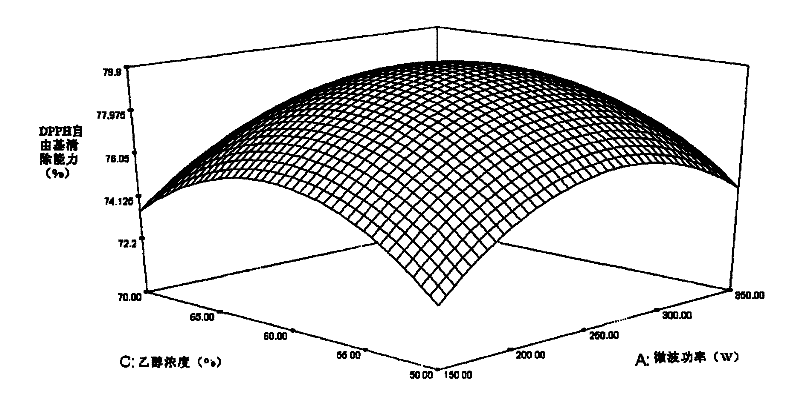

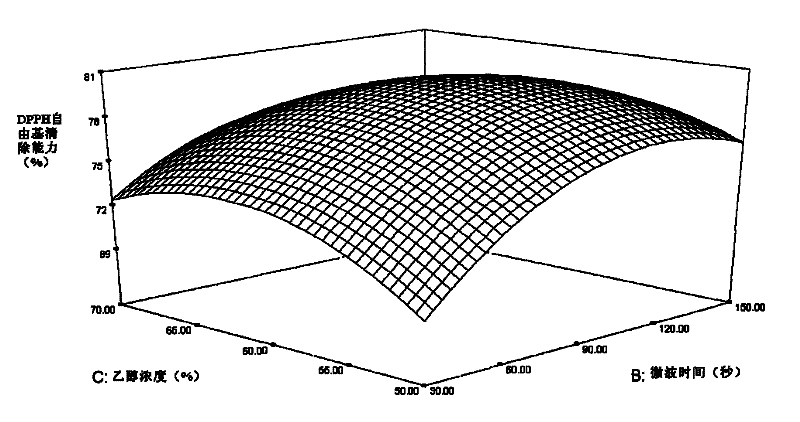

Method used

Image

Examples

Embodiment 1

[0037]Select 1 kg of Ningzishu No. 1 leaf variety, collect and wash fresh sweet potato leaves, dry and crush them through a 60-mesh sieve for use; decolorize and degrease the sieved sweet potato leaf powder with petroleum ether, and the amount of petroleum ether is 5: 1, the treatment time was 3 hours; the decolorized defatted sweet potato leaf powder was added to 60% ethanol aqueous solution, put into microwave equipment and carry out leaching, microwave power 300W, sweet potato leaf powder: ethanol aqueous solution was 1: 25 (by weight percentage), Extract 2 times, each extraction time is 5 minutes. Combine the extracts, filter, recover the solvent from the filtrate, and concentrate under reduced pressure in a vacuum with a vacuum degree of -0.02 to 0.08Mpa and a temperature of 40°C to obtain the crude extract of sweet potato leaves; after obtaining the crude extract of sweet potato leaves, use AB-8 type macroporous resin for adsorption. Wash the macroporous resin with deio...

Embodiment 2

[0044] Select 1 kg of the Ningshu 43-8 leaf variety, collect and wash the fresh sweet potato leaves, dry and pulverize through a 60-mesh sieve for use; decolorize and degrease the sieved sweet potato leaf powder with petroleum ether, and the amount of petroleum ether is 4: 1, the treatment time was 2.5 hours; the decolorized defatted sweet potato leaf powder was added to 70% ethanol aqueous solution, put into microwave equipment and carry out leaching, microwave power 250W, sweet potato leaf powder: ethanol aqueous solution was 1: 25 (by weight percentage), Extract 2 times, each extraction time is 5 minutes. Combine the extracts, filter, recover the solvent from the filtrate, and concentrate under reduced pressure in a vacuum with a vacuum degree of -0.02 to 0.08Mpa and a temperature of 35°C to obtain the crude extract of sweet potato leaves; after obtaining the crude extract of sweet potato leaves, use a D101 macroporous The resin is adsorbed. Wash the macroporous resin with...

Embodiment 3

[0046] Select 0.5 kg of Ningzishu No. 1 leaf variety, collect and wash fresh sweet potato leaves, dry and crush them through a 40-mesh sieve for use; decolorize and degrease the sieved sweet potato leaf powder with petroleum ether, and the amount of petroleum ether is 3: 1, the treatment time was 3 hours; the decolorized defatted sweet potato leaf powder was added to 70% ethanol aqueous solution, put into microwave equipment and carry out leaching, microwave power 300W, sweet potato leaf powder: ethanol aqueous solution was 1: 25 (by weight percentage), Extract 3 times, each extraction time is 3 minutes. Combine the extracts, filter, recover the solvent from the filtrate, concentrate under reduced pressure in vacuum, the vacuum degree is -0.02-0.08Mpa, and the temperature is 35°C to obtain the crude extract of sweet potato leaves; after obtaining the crude extract of sweet potato leaves, use AB-8 type macroporous resin for adsorption. Wash the macroporous resin with deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com