Five-axis numerical control engraving and milling machine for tire sidewall plate

A sidewall, engraving and milling machine technology, applied in milling machine equipment, details of milling machine equipment, metal processing machinery parts, etc., can solve the problems that the size of the clamping workpiece cannot be too large, the dustproof performance is unstable, and the manufacturing and assembly are difficult. , to achieve the effect of good dustproof effect, fast processing speed, convenient manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

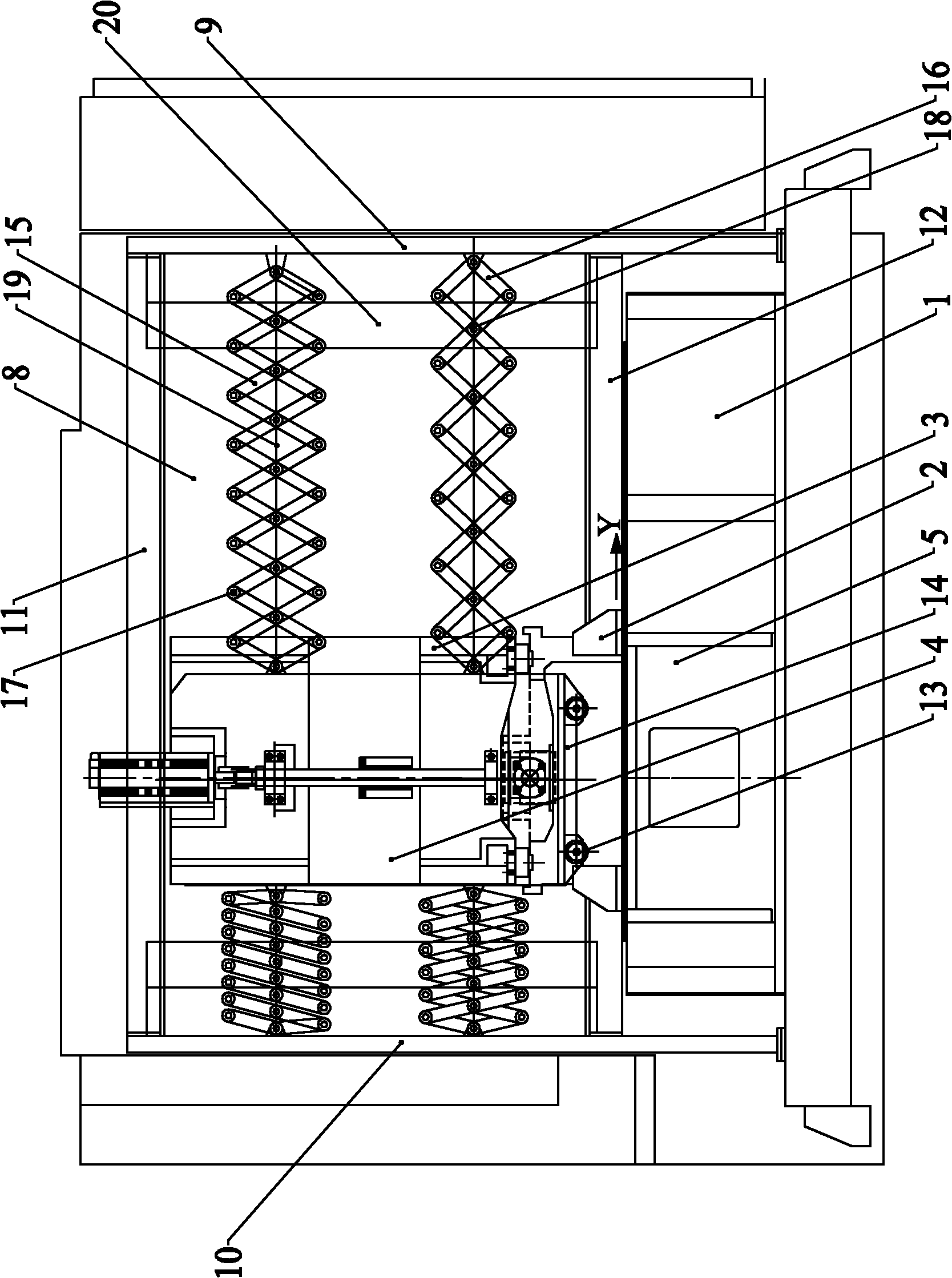

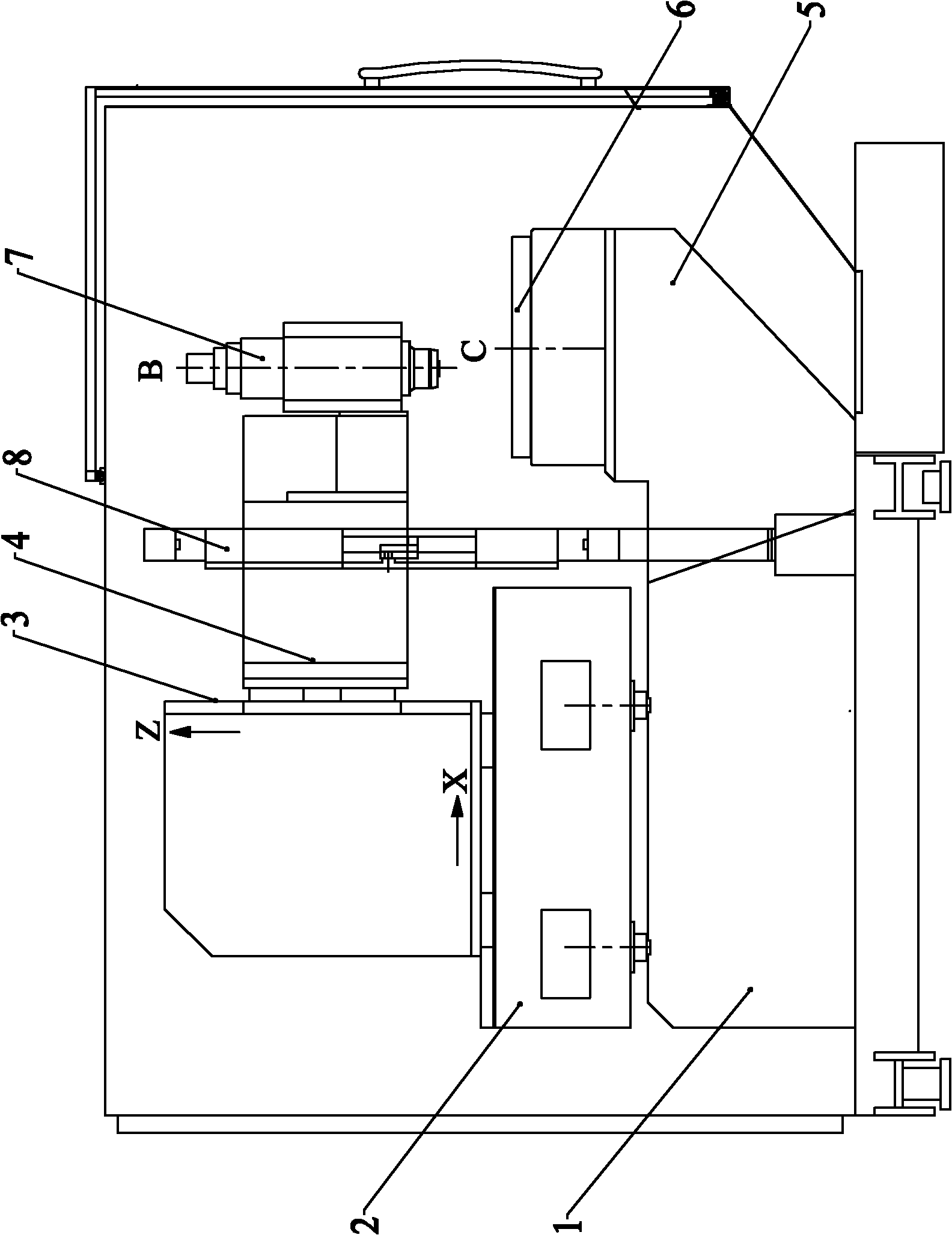

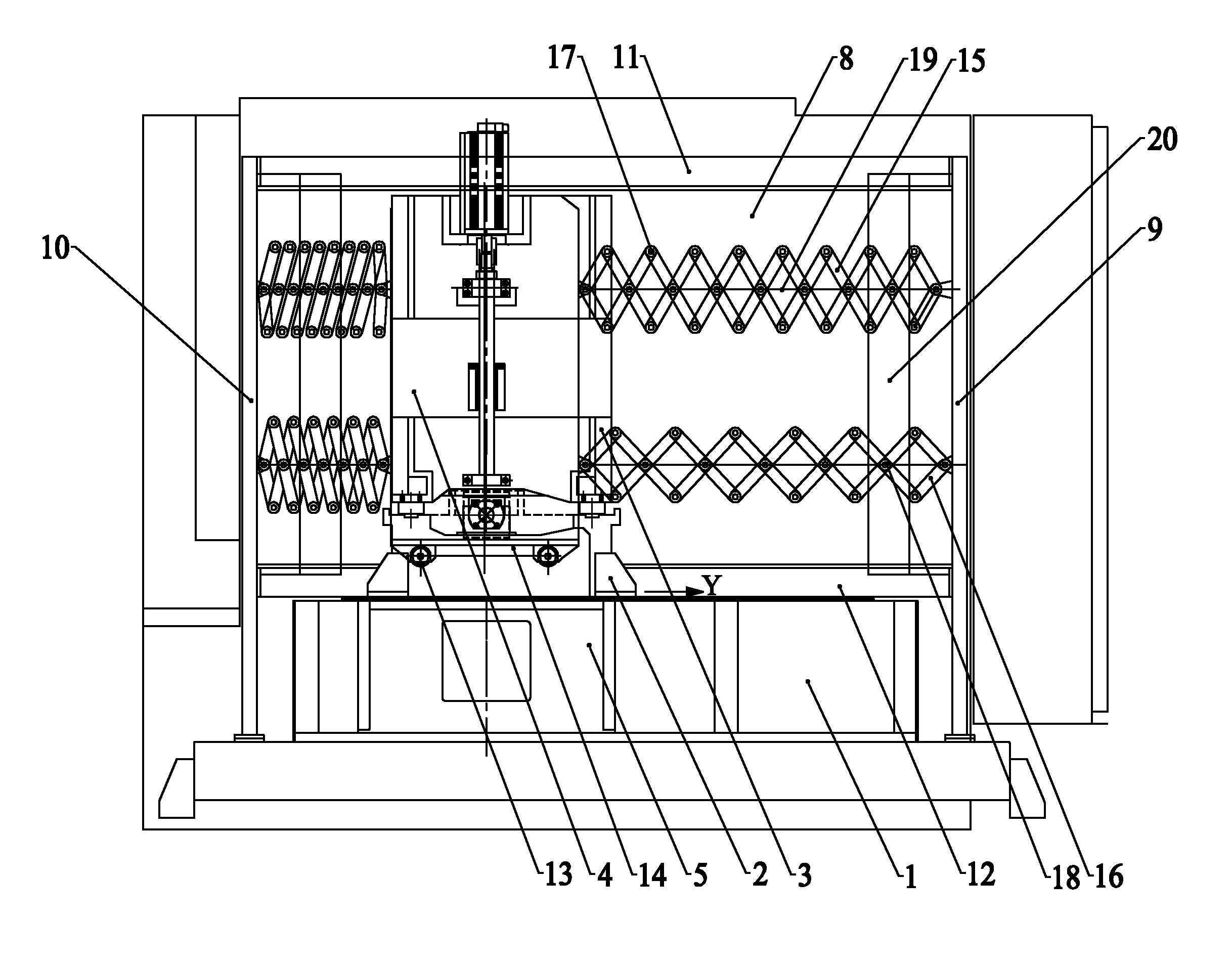

[0015] refer to Figure 1 to Figure 2 , this embodiment includes a base 1, a transverse sliding seat 2, a column 3, a column carriage 4, a support seat 5, a numerical control turntable 6, a spindle swing head 7, a machine tool dustproof device 8, a control device and a driving device; the base 1 and the lateral There are ball guide rails and ball screws between the slide seats 2, between the horizontal slide seat 2 and the column 3, between the column 3 and the column carriage 4; the column 3 is driven by the driving device through the ball guide rail and the ball screw along the first The linear axis X moves back and forth on the horizontal slide 2; the horizontal slide 2 moves left and right on the base 1 along the second linear axis Y through the ball guide rail and ball screw driven by the drive device; the column carriage 4 is driven by the drive device The bottom moves up and down on the column 3 along the third linear axis Z through the ball guide rail and the ball scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com