Automatic marking device of round bar

A round bar, automatic technology, applied in printing, stamping and other directions, can solve the problems of difficult continuous production of stamping equipment, high labor intensity of workers, reduced equipment utilization, etc., to improve safety, work efficiency and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

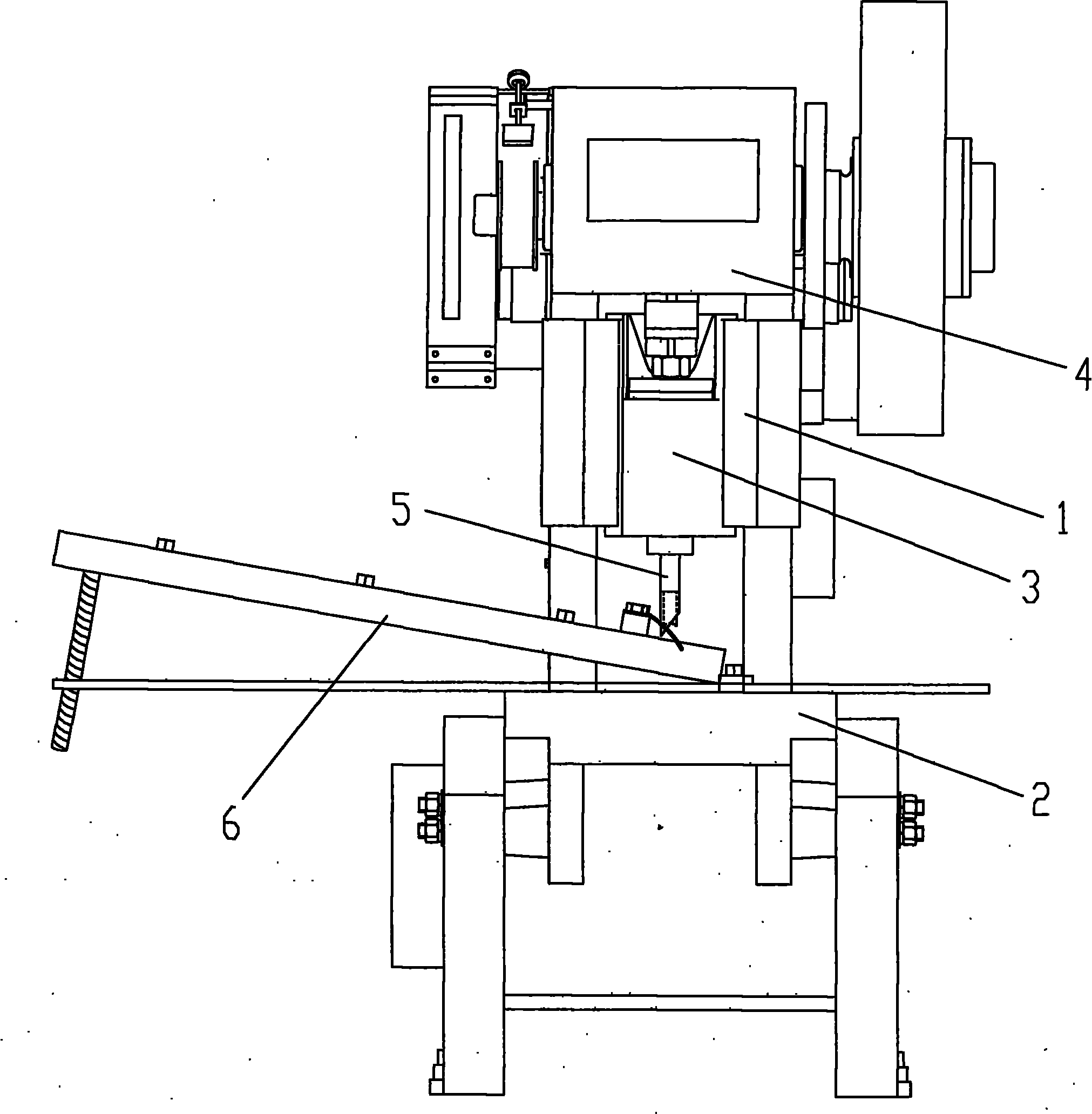

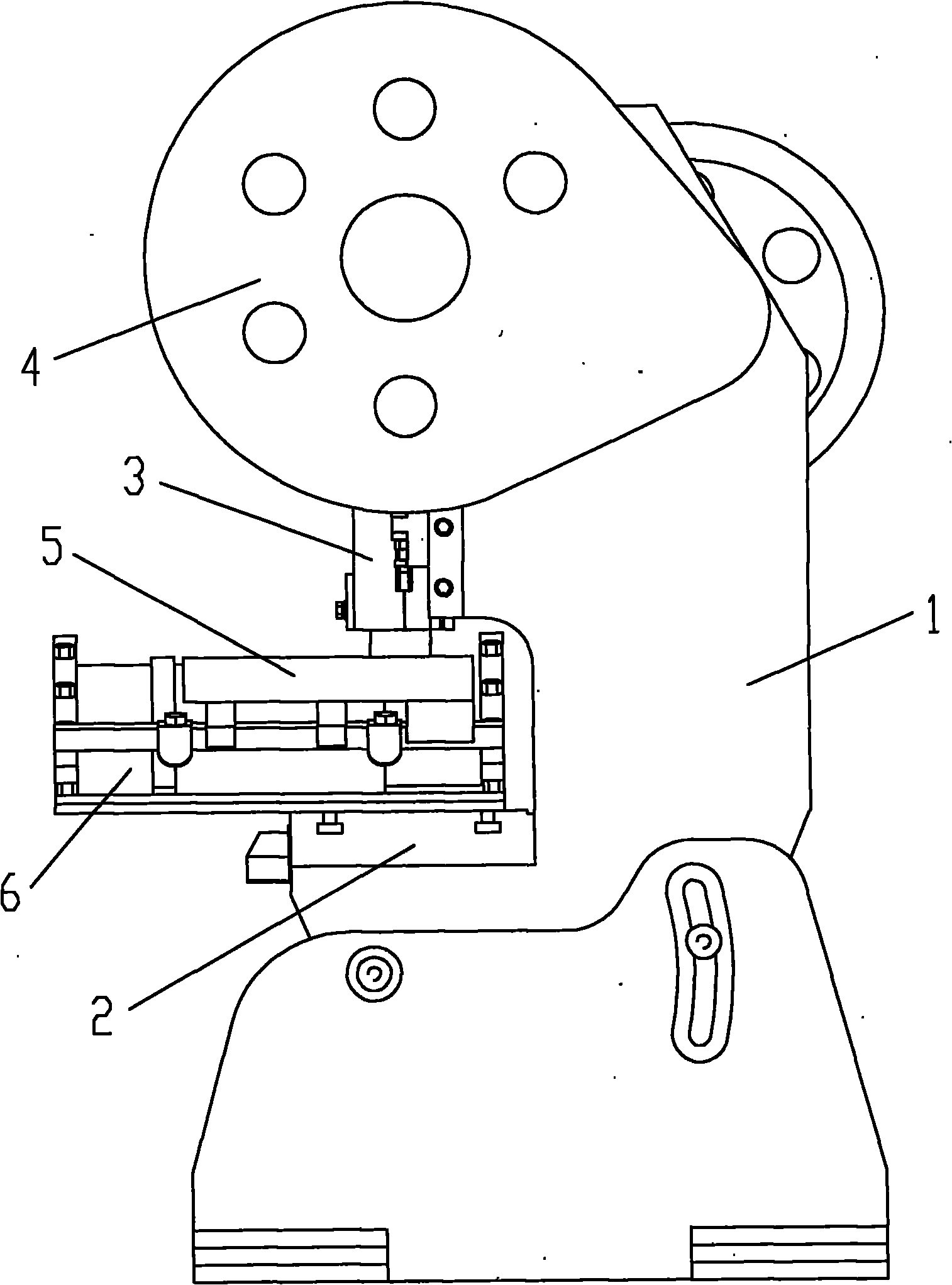

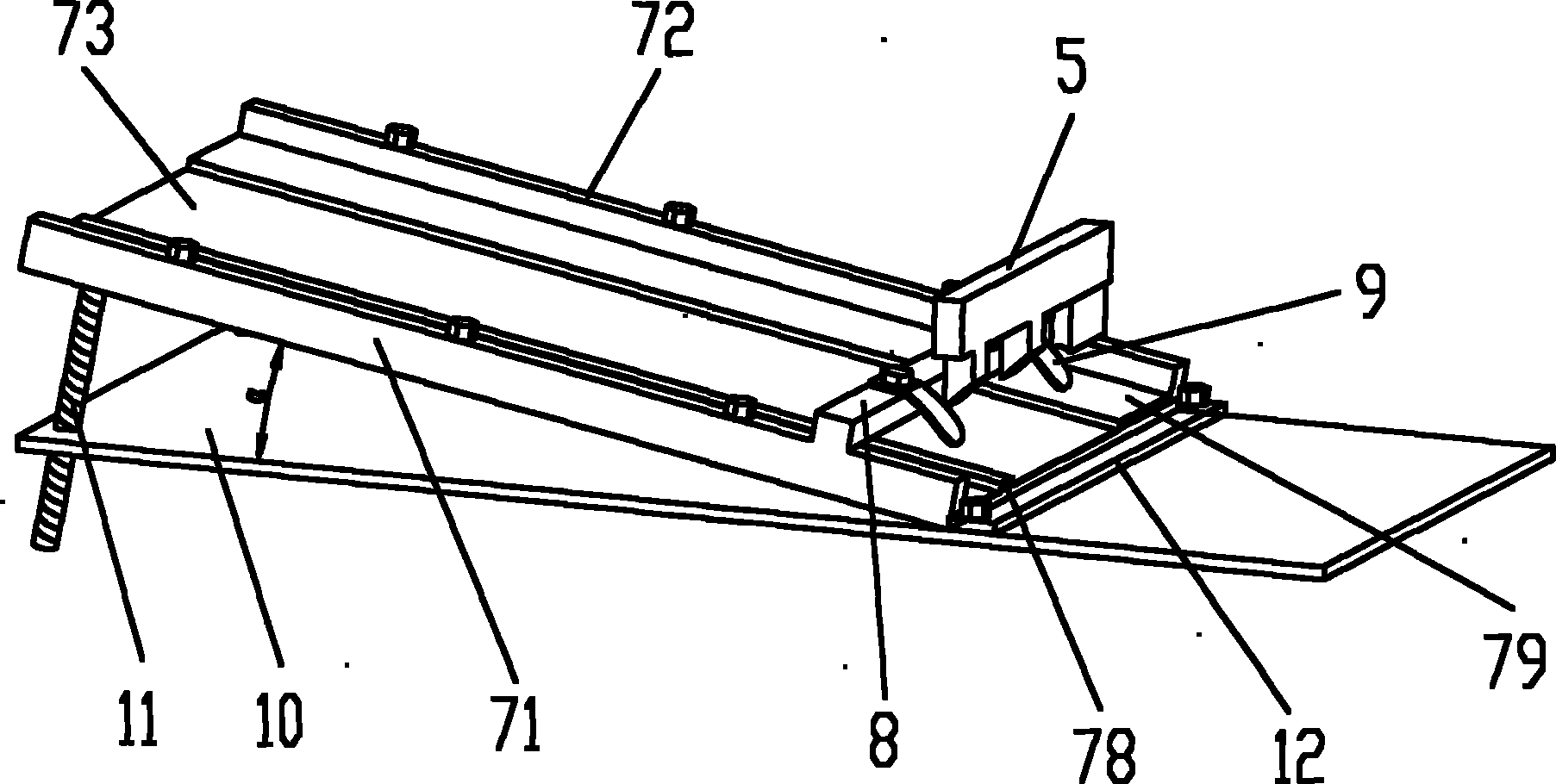

[0026] see Figure 1 to Figure 8 , the round bar marking automatic marking device in this embodiment is made up of stamping equipment, punching die 5 and round bar feeding equipment 6, wherein the stamping equipment includes a frame body 1, a working platform 2 and a transmission mechanism 4 with a stamping block 3, the working platform 2 and the transmission mechanism 4 are installed on the frame body 1, the working platform 2 is horizontal, the working platform 2 is located below the transmission mechanism 4, and the stamping block 3 can punch downward under the action of the transmission mechanism 4. The stamping equipment in the present invention is the same as or similar to the prior art, and will not be described in detail here.

[0027] The punching die 5 in this embodiment has an integrated structure, and the punching die 5 is installed in the punching block 3 of the punching equipment, and the punching block 3 drives the punching die 5 to perform punching downward. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com