Hot rolled steel coil taping device

A technology of hot-rolled steel coils and steel coils, which is applied in the field of strapping devices, can solve the problems of loose strapping, complicated procedures, and injuries caused by loose coils, and achieves reduced probability of abnormal fracture, good stability and reliability, and reduced labor costs. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

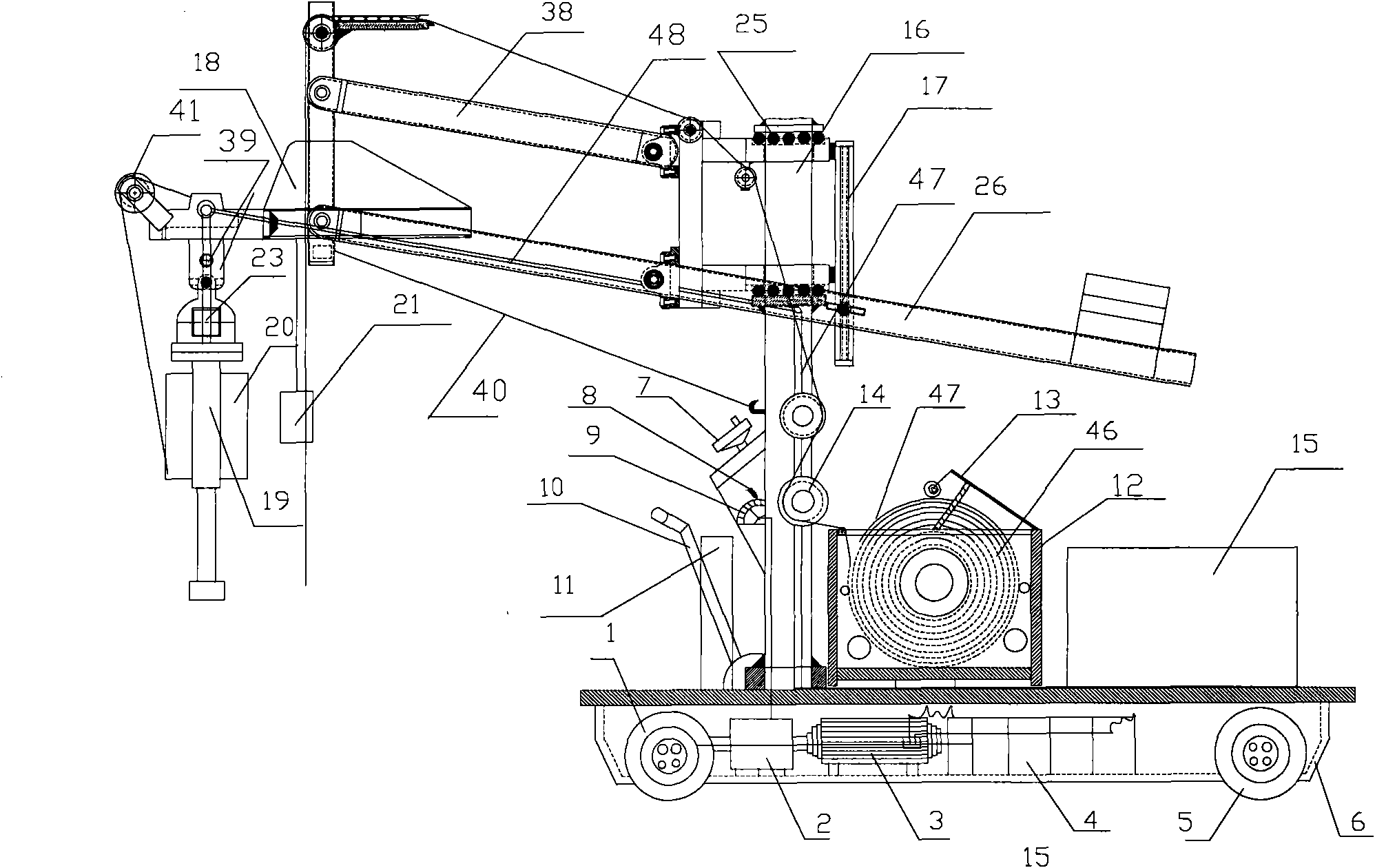

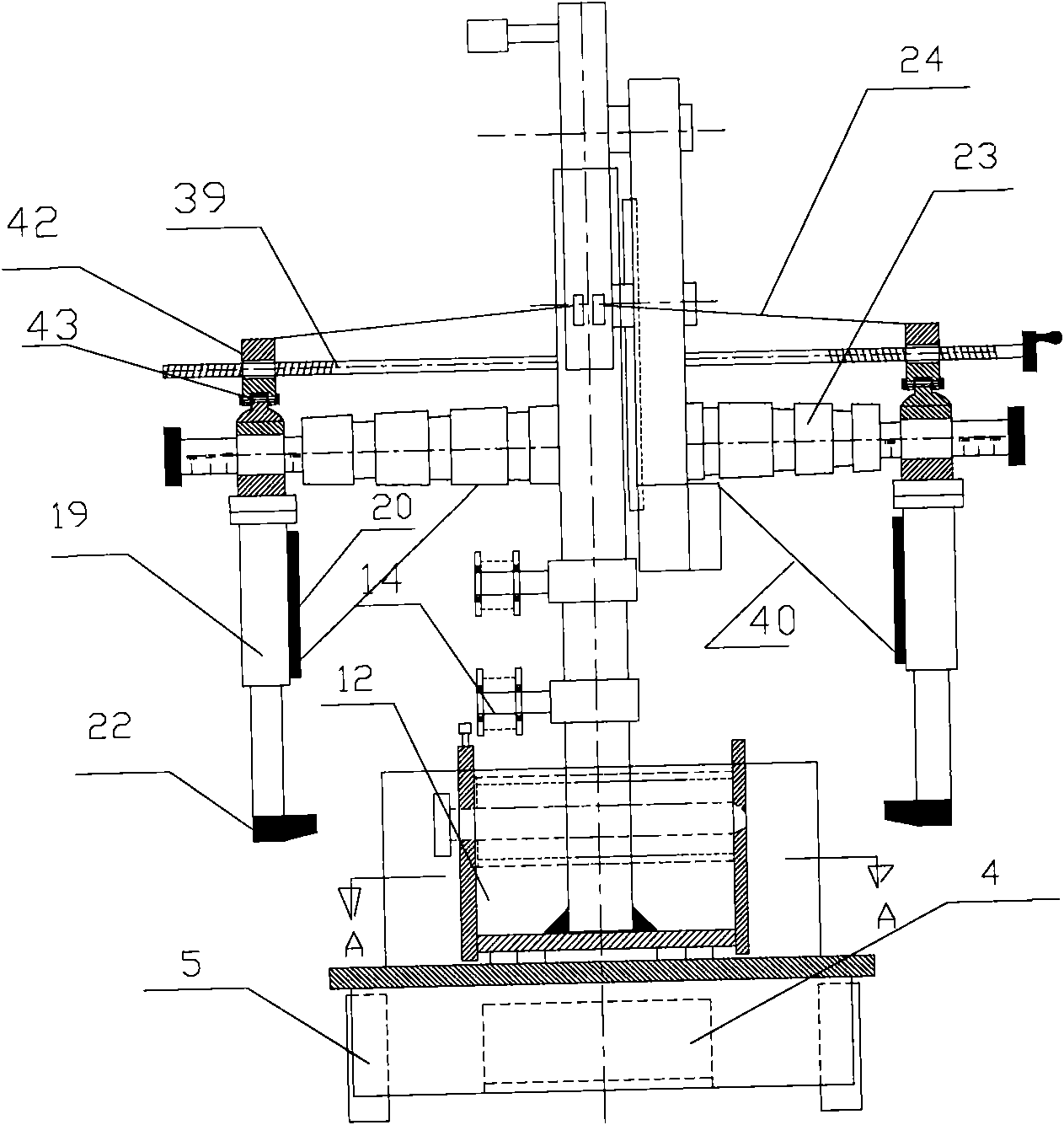

[0041] 1. The hot-rolled steel coil strapping device of the present invention comprises: a driving device, a bundling box trolley connected with the driving device, a hydraulic device, a strapping and pressing device for bundling steel coils, a strapping machine and a shaft to the locking fixture. The drive device includes: a drive motor 3, a gearbox 2 connected to the drive motor, a drive wheel 1 and a drive wheel steering wheel 7.

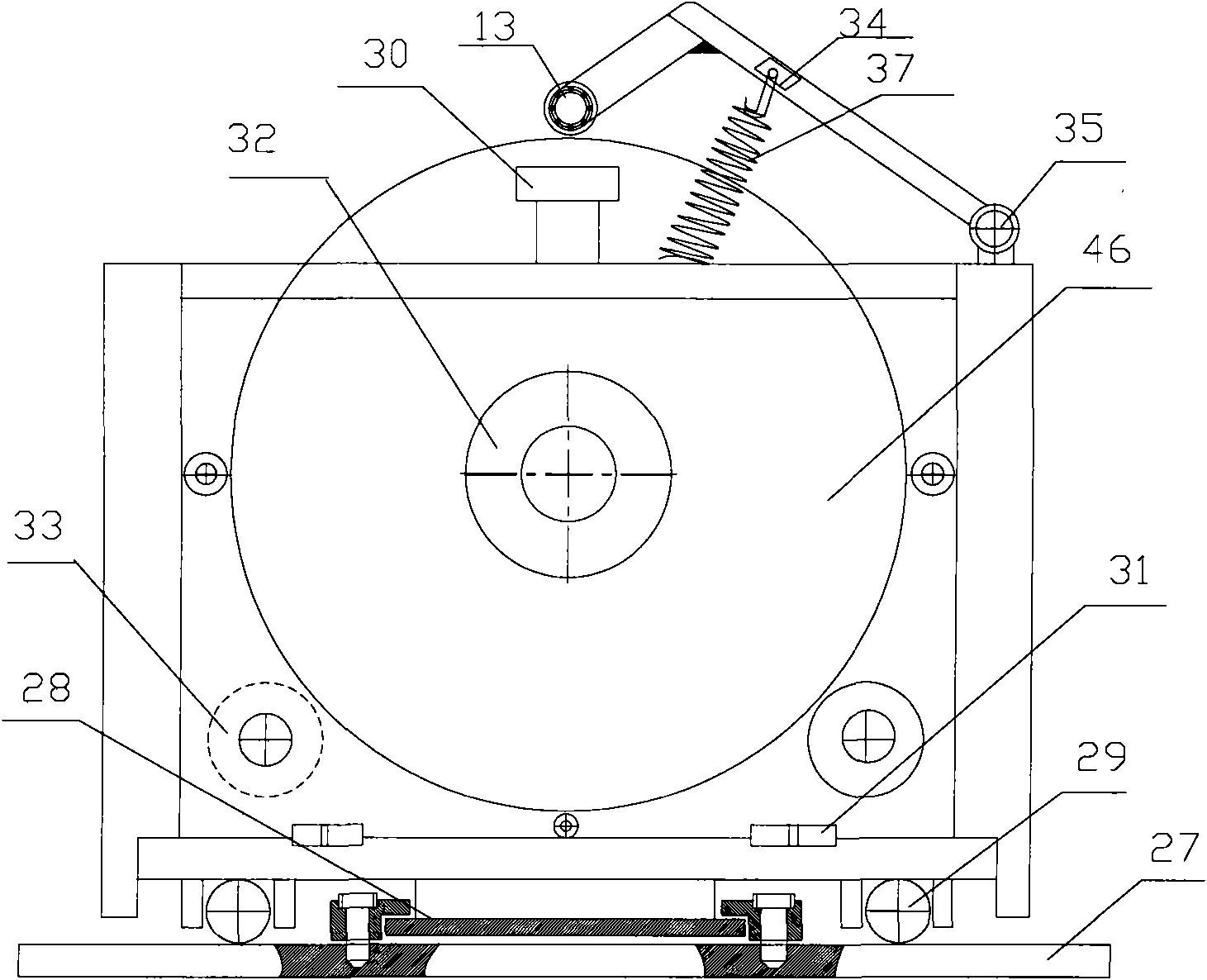

[0042] The bundling box trolley connected with the driving device includes: a bundling box 12 arranged on the device trolley, which can rotate horizontally in situ and a steel coil bracket therein, a working column 16 arranged on the device trolley; The strap compression beam 34 above the bundling box 12 is hooked to the strap compression spring 37 of the strap compression beam 34 and its connection, and the strap compression roller 13 used to compress the steel coil; Case 12 two side case walls, are used for the strap inner cover round bar 36 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com