Preparation method for gamma-alumina nanotube with prior exposure of (111) face

A kind of aluminum oxide nano, {111} technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of uneven morphology, unfavorable large-scale synthesis of nanotube materials, poor uniformity of product morphology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

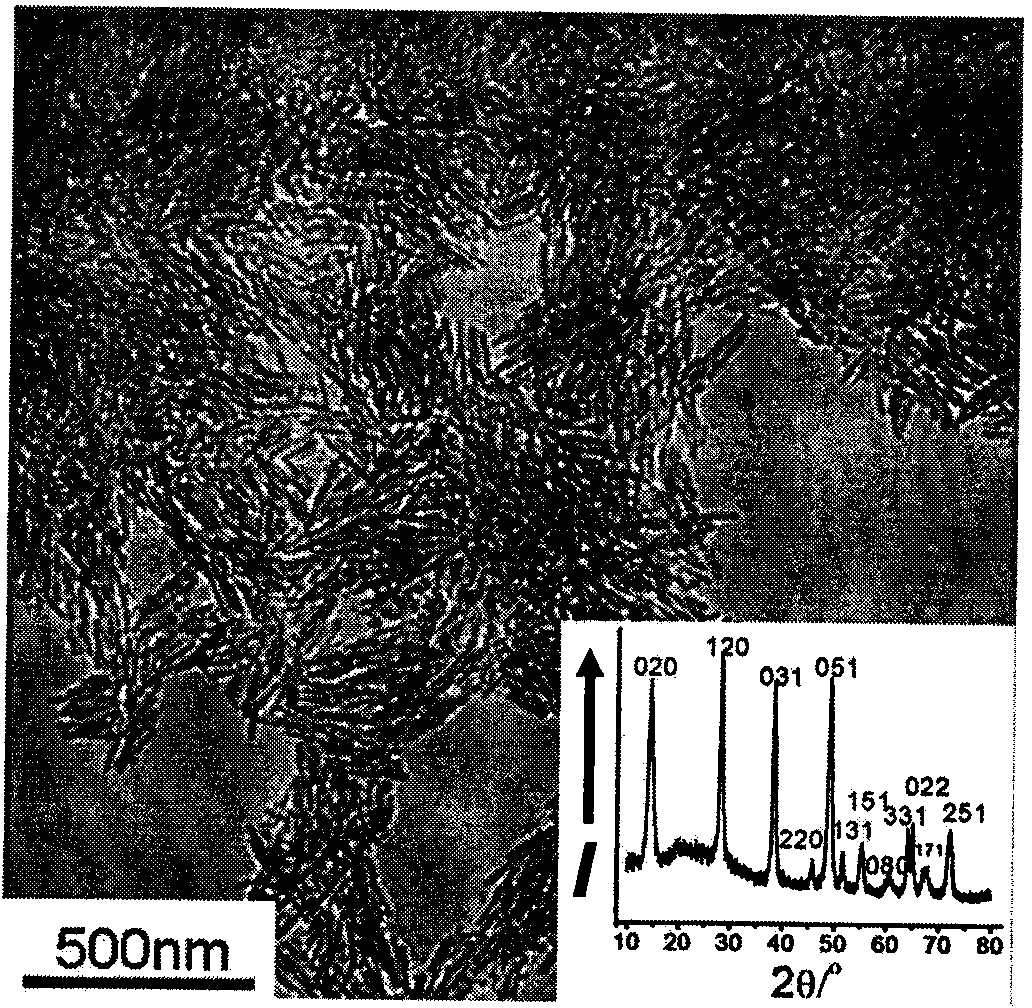

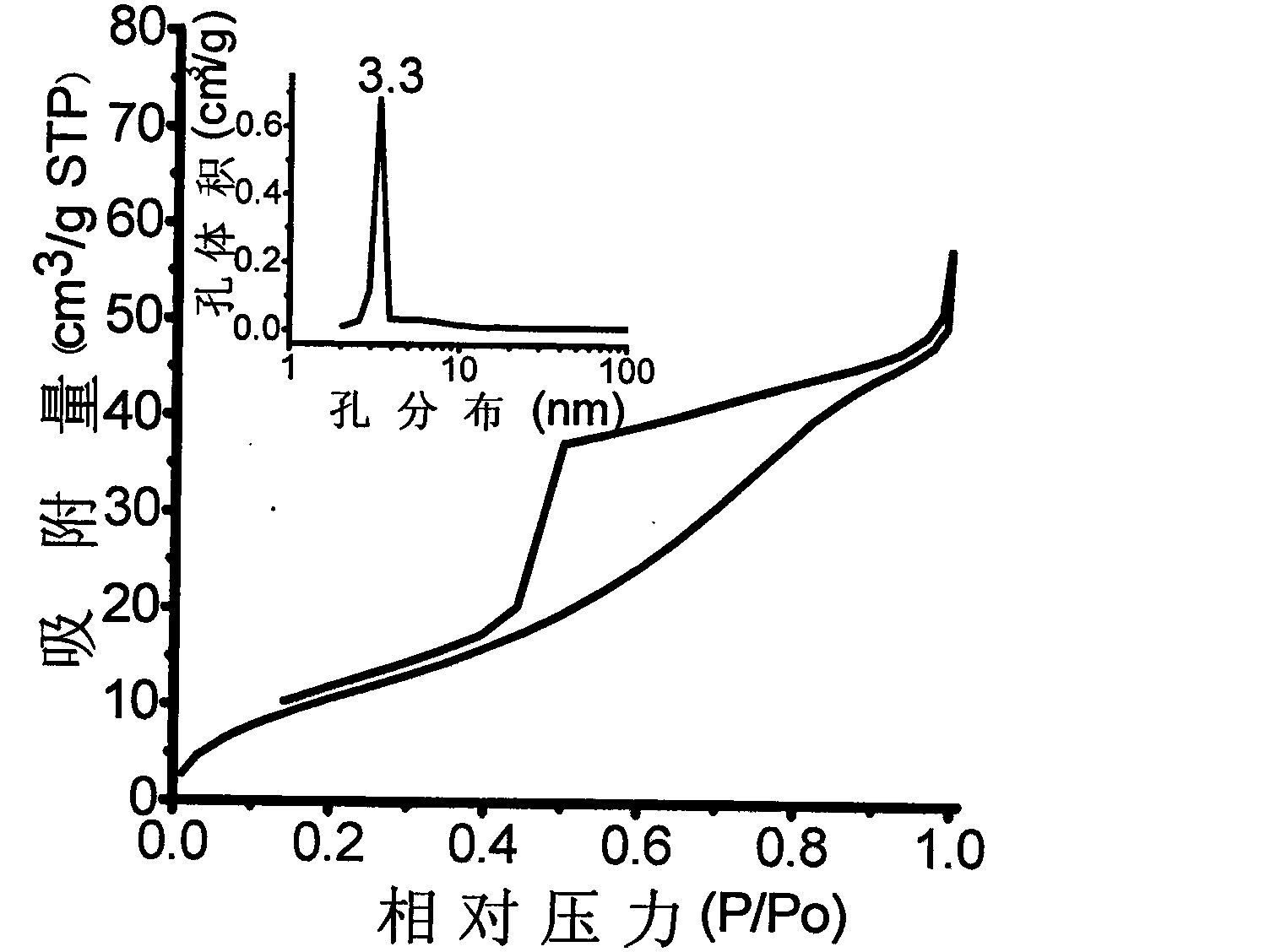

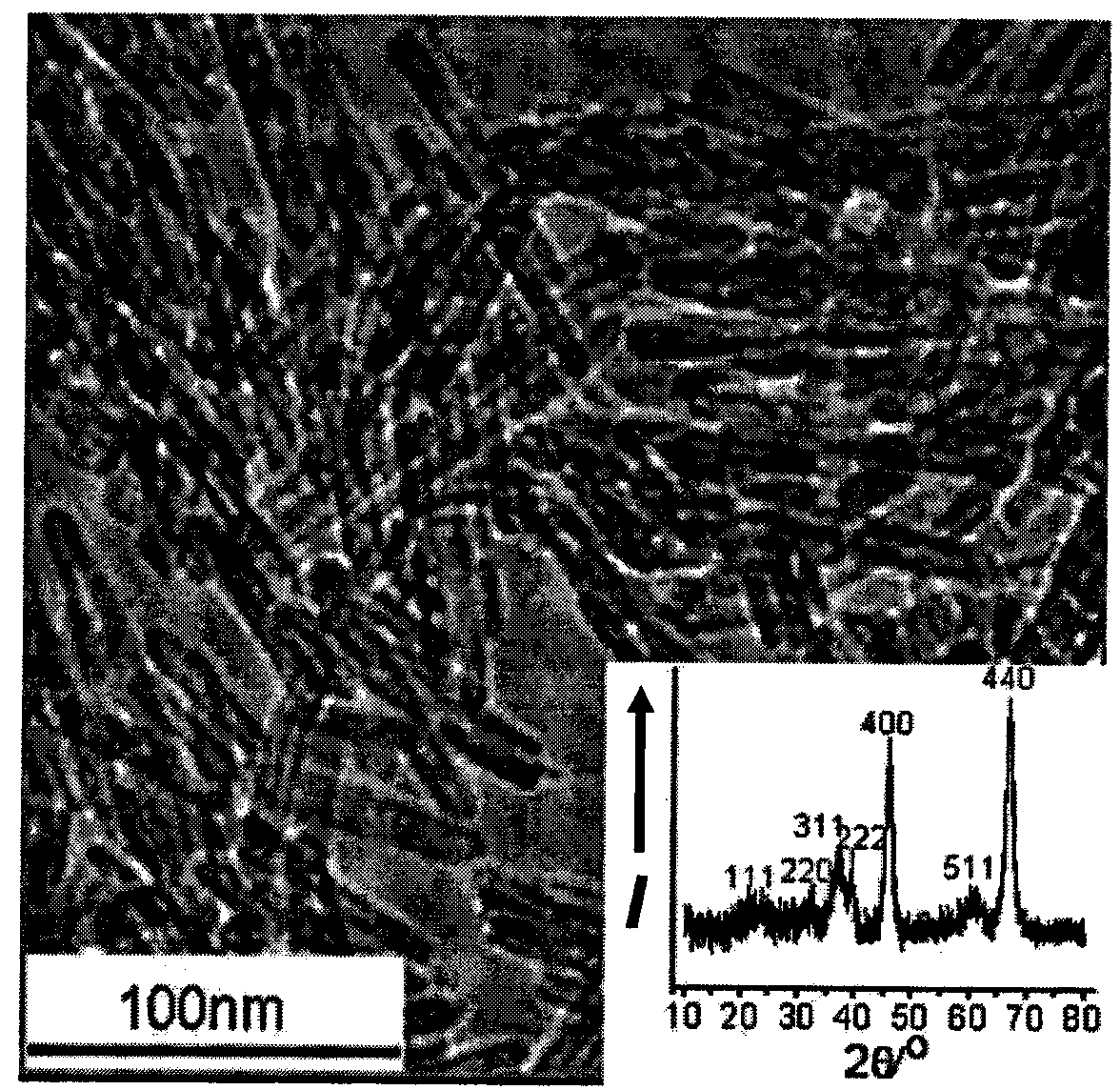

[0030] Prepare 250ml of 0.25mol / L sodium oleate solution. Take 20ml of 0.25mol / L sodium oleate solution and mix it with the same volume of aluminum sol (provided by Zhejiang Yuda Chemical Co., Ltd., model AlT-10-4, the same below), mix it for a period of time, put it in a closed container, and put it in water at 180°C Heat the reaction for 72 hours. After the reaction is over, take out the autoclave, cool to room temperature, separate the lower precipitate, centrifuge, wash, and dry to obtain AlOOH nanotubes. The TEM photos and XRD patterns are shown in figure 1 ; Adsorption-desorption curves and pore distribution curves are shown in figure 2 . AlOOH nanotubes were calcined in air at 500°C for 4 hours to obtain γ-alumina nanotubes with preferentially exposed {111} planes. The nanotubes were 100-200 nanometers long and 8-10 nanometers in outer diameter. The TEM photos and XRD patterns See image 3 , and its high-resolution TEM transmission picture is shown in Figure 4 , t...

Embodiment 2

[0032] Prepare 250 ml of 0.10 mol / L sodium campsylate solution. Take 25ml of 0.10mol / L sodium campsylate solution and mix it with 5ml sol, stir it for a period of time, put it in a closed container, and conduct a hydrothermal reaction at 150°C for 48 hours. After the reaction, take out the autoclave, cool to room temperature, separate The lower layer is precipitated, centrifuged, washed, and dried to obtain AlOOH nanotubes. The AlOOH nanotubes are calcined at 500°C for 4 hours in air to obtain γ-alumina nanotubes with preferentially exposed {111} planes. The nanotubes are 100-200 nanometers long , the outer diameter is 8-10 nanometers, the hydroxyl density reaches 1.99mmol / g, and the acid density reaches 0.489mmol / g. , its TEM photo and XRD collection of patterns are the same as Example 1 results. .

Embodiment 3

[0034] Prepare 250ml of 0.50mol / L sodium lauryl sulfate solution. Mix 10ml of 0.50mol / L sodium lauryl sulfate solution with 20ml of aluminum sol, stir for a period of time, put it in a closed container, and conduct a hydrothermal reaction at 180°C for 24 hours. After the reaction, take out the autoclave and cool it to room temperature. Separate the lower layer of sediment, centrifuge and wash, dry,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com