Preparation method of ultrafine single crystal platinum nanotubes with openings at both ends of 1nm ultrathin tube wall

A platinum nanometer and nanotube technology, which is applied in the field of preparation of single crystal platinum nanomaterials, can solve the problems of unable to guarantee the hollow and transparent structure of nanotubes, failing to achieve the minimum size at the same time, and achieve outstanding advantages, simple preparation method, The effect of high active specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

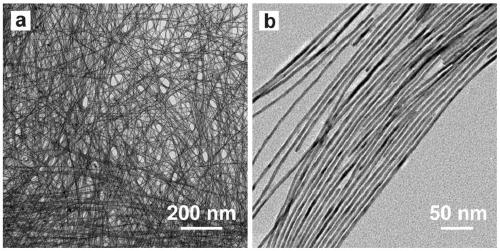

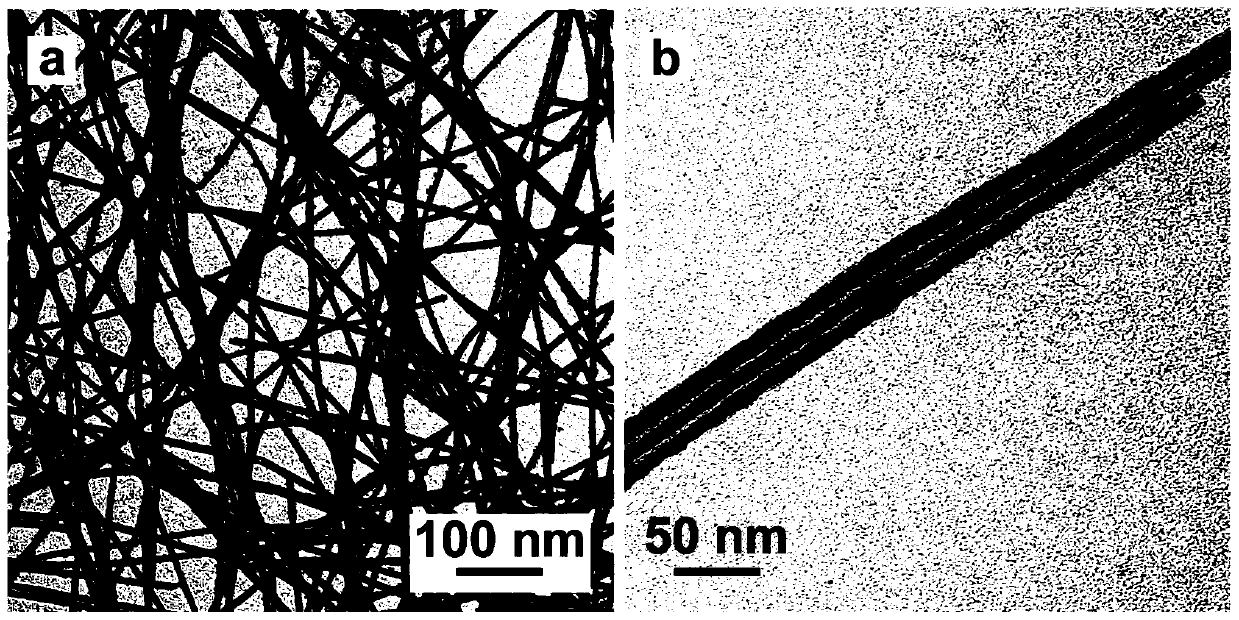

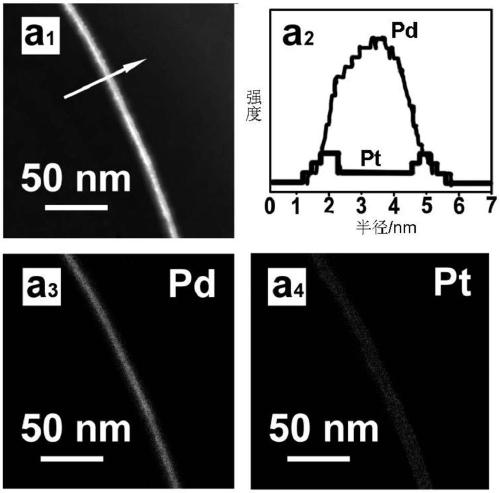

[0023] (1) Put 0.7 mg of single-crystal Pd nanowire powder with a diameter of 4.8 nm and 1 mL of ethylene glycol solution into a beaker, ultrasonicate at 50 Hz for 120 minutes to promote dissolution, and then put the mixed solution in a water bath, at a temperature of 50 ° C Under magnetic heating and stirring for 20 minutes, the stirring rate was controlled at 245r / min. Subsequently, 2.5mL of chloroplatinic acid solution with a concentration of 6mM was slowly added dropwise to the mixed solution at a rate of 2mL / h, and the temperature was continued at 50°C. Heat and stir for 9 hours, then centrifuge the heated mixture at 6000r / min for 15 minutes, wash it twice with ethanol-acetone solution with a volume ratio of 2:1, and finally dry it in a blast drying oven at 70°C. A large number of regular Pd@Pt core-shell nanowire powders were obtained.

[0024] (2) Dissolve 0.5 mg of Pd@Pt nanowire powder and 0.8 mg of ferric chloride powder prepared in step (1) in 1 mL of hydrochloric a...

Embodiment 2

[0027] (1) Put 0.2 mg of single-crystal Pd nanowire powder with a diameter of 4.8 nm and 1 mL of ethylene glycol solution into a beaker, ultrasonicate at 50 Hz for 70 minutes to promote dissolution, and then put the mixed solution in a water bath, at a temperature of 55 ° C Under magnetic heating and stirring for 30 minutes, the stirring rate was controlled at 220r / min. Subsequently, 2 mL of chloroplatinic acid solution with a concentration of 5 mM was slowly added dropwise to the mixed solution at a rate of 1 mL / h, and continued heating at 55 ° C. After stirring for 10 hours, the heated mixture was centrifuged at 8000r / min for 15 minutes, washed twice with ethanol-acetone solution with a volume ratio of 2:1, and finally dried in a blast drying oven at 70°C to obtain Plenty of regular Pd@Pt core-shell nanowire powders.

[0028] (2) Dissolve 1 mg of Pd@Pt nanowire powder and 0.5 mg of ferric chloride powder prepared in step (1) in 1 mL of hydrochloric acid solution with a pH va...

Embodiment 3

[0032] (1) 1 mg of single crystal Pd nanowire powder with a diameter of 4.8 nm and 1 mL of ethylene glycol solution are put into a beaker, and 50 Hz ultrasonic (50 Hz) is used for 200 minutes to promote dissolution, and then the mixed solution is put into a water bath and heated at 80 Magnetic heating and stirring at a temperature of ℃ for 10 minutes, the stirring rate was controlled at 180r / min, and then, at a rate of 2.5mL / h, 5mL of a chloroplatinic acid solution with a concentration of 3mM was slowly added dropwise to the mixed solution, and continued at 80 Heat and stir at ℃ for 12 hours, then centrifuge the heated mixture at 4000r / min for 15 minutes, wash it twice with ethanol-acetone solution with a volume ratio of 2:1, and finally put it in a blast drying oven at 70℃ After drying, a large number of regular Pd@Pt core-shell nanowire powders are obtained.

[0033] (2) Dissolve 3 mg of Pd@Pt nanowire powder and 0.3 mg of ferric chloride powder prepared in step (1) in 1 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com