Light-emitting device, aluminum nitride product, aluminum nitride single crystal and manufacturing method and application thereof

A production method, aluminum nitride technology, applied in chemical instruments and methods, single crystal growth, single crystal growth, etc., to achieve the effect of avoiding mechanical damage and pyrolysis, and high-quality recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

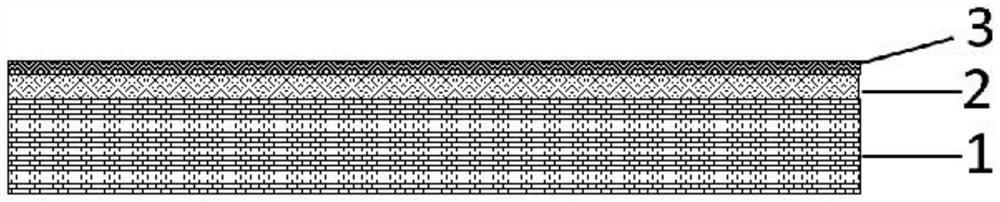

[0091] In the present embodiment, aluminum namide aluminum, 300 nano thickness is prepared on the sapphire substrate, and the thin layer of 5 nano-aluminum oxy nitrogen Alon is prepared by reaction magnetron sputtering on aluminum. A composite structure is obtained. The composite structure is then placed in an annealing furnace to perform a high temperature annealing treatment to obtain a surface-free aluminum nitride single crystal.

[0092] The surface lossless aluminum single crystal template of the present embodiment includes the following steps:

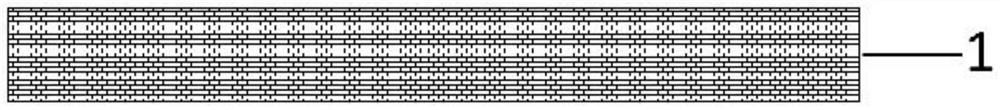

[0093] 1) Select the sapphire substrate of the 2 inch (0001) crystal plane of single-sided polishing, using acetone for 10 minutes, then blow dry with nitrogen, such as figure 1 As shown, 1 is a sapphire substrate 1 after cleaning.

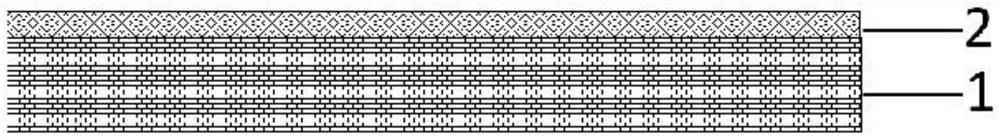

[0094] 2) After washing the lamethase, a 300 nm thick aluminum nitride film layer 2 is deposited by the method of reaction magnetron sputtering. figure 2 It is shown.

[0095] The deposition temperature...

Embodiment 2

[0102] In the present embodiment, aluminum nitride of 500 nano thickness is prepared on the sapphire substrate by reaction magnetron, and 5 nanometers Alon is prepared by reactive magnetron sputtering on the aluminum. A composite structure is obtained. The composite structure is then placed in an annealing furnace to perform a high temperature annealing treatment to obtain a surface-free aluminum nitride single crystal.

[0103] The surface lossless aluminum single crystal template of the present embodiment includes the following steps:

[0104] 1) Select the sapphire substrate of the 2-inch (0001) crystal surface of a single-sided polishing, using acetone for ultrasonic cleaning for 10 minutes, and then blows dry with nitrogen.

[0105] 2) After washing the lametage of the sapphire substrate, a 300 nm thick aluminum nitride film layer is deposited by a method of reaction magnetron sputtering.

[0106] The deposition temperature is 500 ° C, the deposition power is 3000W, the gas a...

Embodiment 3

[0113] In the present embodiment, aluminum namide aluminum is prepared on a sapphire substrate using a reaction magnetron sputtering, and 5 nanometers Alon is prepared by reactive magnetron sputtering on aluminum. A composite structure is obtained. The composite structure is then placed in an annealing furnace to perform a high temperature annealing treatment to obtain a surface-free aluminum nitride single crystal.

[0114] The surface lossless aluminum single crystal template of the present embodiment includes the following steps:

[0115] 1) Select the sapphire substrate of the 2-inch (0001) crystal surface of a single-sided polishing, using acetone for ultrasonic cleaning for 10 minutes, and then blows dry with nitrogen.

[0116] 2) After washing the lametage of the sapphire substrate, a 300 nm thick aluminum nitride film layer is deposited by a method of reaction magnetron sputtering.

[0117] The deposition temperature is 500 ° C, the deposition power is 3000W, the gas atmos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com