A kind of positive electrode material of lithium ion battery and preparation method thereof

A lithium-ion battery and cathode material technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as ammonia nitrogen pollution, and achieve the effects of controllable process, uniform distribution of effective metals, and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to the chemical formula Fe 0.1 mn 0.9 HPO 4 ·3H 2 O Weigh 0.1mol metallic iron and 0.9mol metallic manganese and dissolve them in a mixed solution of 200g deionized water and 1mol phosphoric acid, and keep stirring and mixing for 1 hour; the resulting solution is warmed up to 50 degrees for 10 hours, and then slowly added to the system Add 100 g of ethanol, and at this time, a precipitate occurs in the system; the obtained precipitate is washed 3 times with deionized water and ethanol, and then dried in a 50-degree oven for 10 hours. After the obtained powder is broken, it is the precursor Fe of lithium-ion battery cathode material. 0.1 mn 0.9 HPO 4 ·3H 2 O.

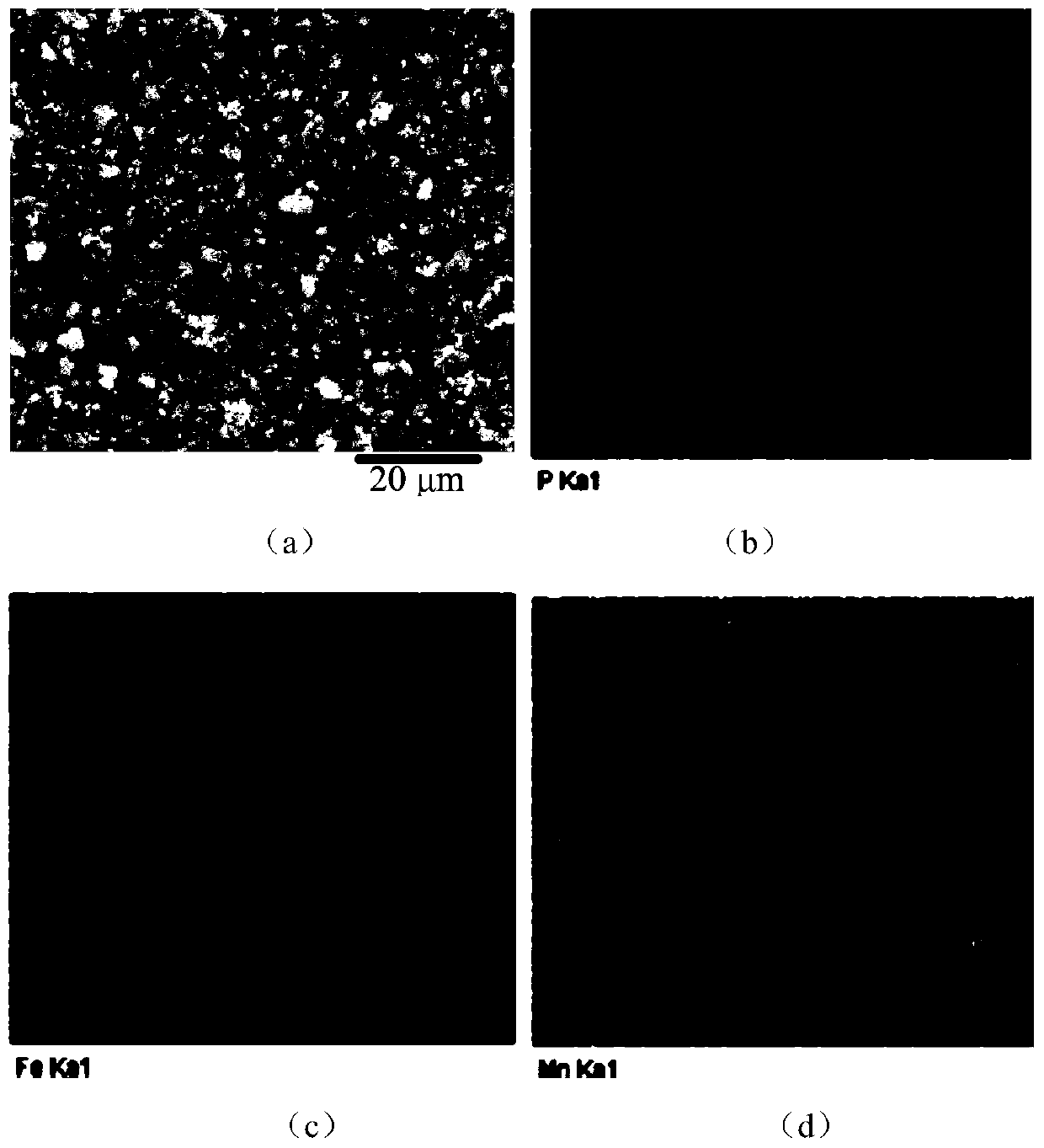

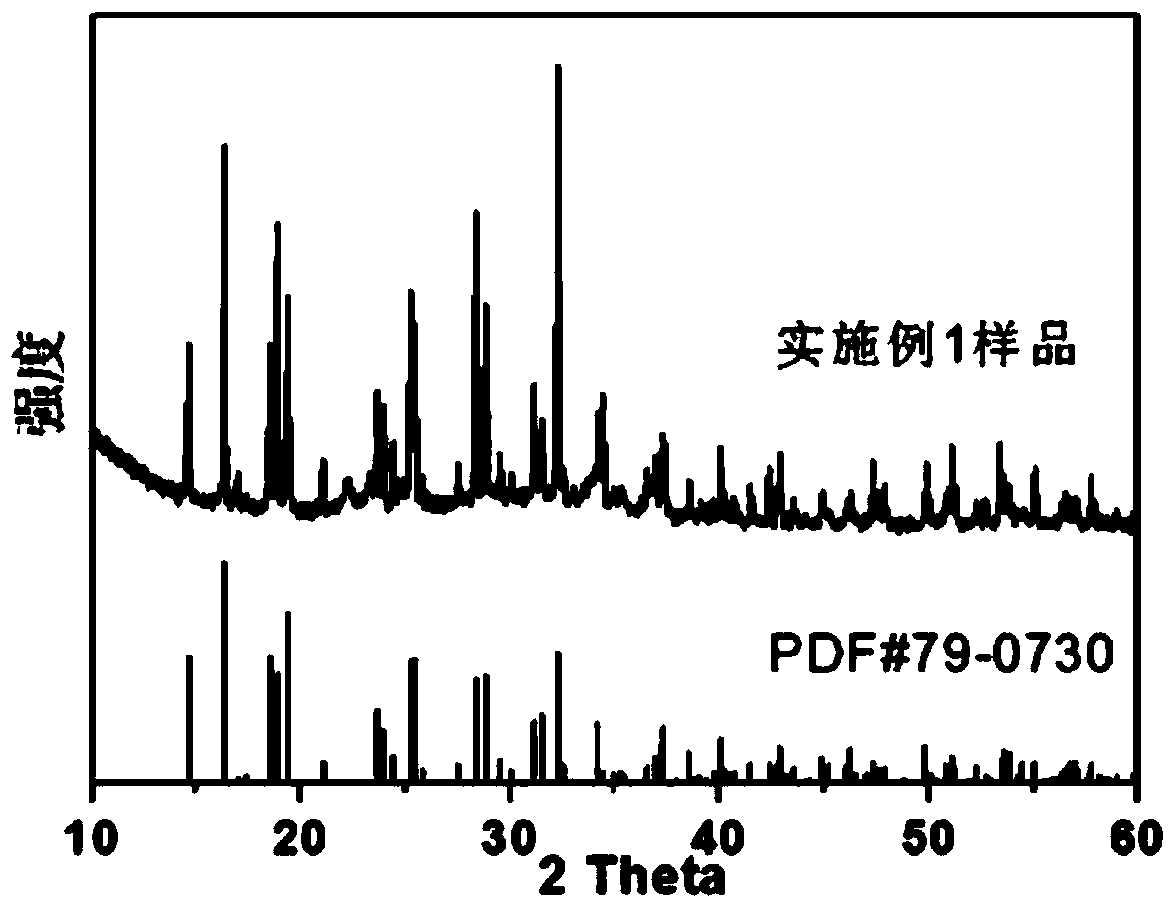

[0030] Scanning electron microscope observation is carried out to the lithium-ion battery anode material precursor that obtains, the result is as follows figure 1 shown. from figure 1 It can be seen that the particle size D50 of the obtained lithium-ion battery cathode material precursor is 3.2...

Embodiment 2

[0033] According to the chemical formula Fe 0.2 mn 0.79 Ni 0.01 HPO 4 ·3H 2 O takes by weighing 2mol ferrous oxide, 7.9mol metal manganese and 0.1mol metal nickel and is dissolved in the mixed solution of 2000g deionized water and 40mol phosphoric acid, and continues to stir and mix 4 hours; The solution obtained is warming up to 90 degree of reaction 2 hours, Then 20,000 g of ethanol was slowly added to the system, and a precipitate was formed in the system at this time; the obtained precipitate was washed 3 times with deionized water and ethanol, and then dried in an oven at 80 degrees for 2 hours. After the obtained powder is broken, it is the precursor Fe of lithium-ion battery cathode material. 0.2 mn 0.79 Ni 0.01 HPO 4 ·3H 2 O.

Embodiment 3

[0035] According to the chemical formula Fe 0.3 mn 0.68 co 0.01 Mg 0.01 HPO 4 ·3H 2O take by weighing 0.3mol ferrous carbonate, 0.68mol manganese carbonate, 0.01mol cobalt carbonate and 0.01mol magnesium hydroxide and dissolve in the mixed solution of 300g deionized water and 2mol phosphoric acid, and keep stirring and mixing for 2 hours; React at 80°C for 3 hours, then slowly add 350g of methanol to the system, at this time, a precipitate occurs in the system; the obtained precipitate is washed with deionized water and ethanol for 3 times, and then dried in a 70°C oven for 3 hours. After the obtained powder is broken, it is the precursor Fe of lithium-ion battery cathode material. 0.3 mn 0.68 co 0.01 Mg 0.01 HPO 4 ·3H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com