Method for preparing fully organic high-dielectric copolymers with side chains containing polyaniline chain segments

A polyaniline chain, high dielectric technology, used in organic insulators, plastic/resin/wax insulators, etc., to achieve the effects of simple process, strong controllability, high scientific value and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

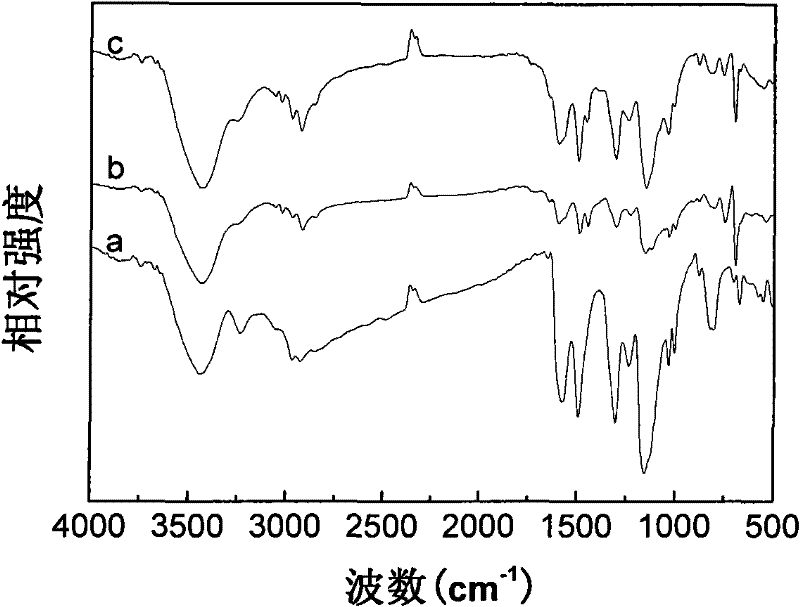

[0026] Add 0.08 mol of sodium styrene sulfonate and 6.68 mL of aqueous hydrochloric acid solution with a mass fraction of 37% into 160 mL of deionized water, stir for 1 hour, then add 0.08 mol of aniline, and dropwise add 0.08 mol of The 160mL aqueous solution of ammonium persulfate was continued to react for about 4 hours after the completion of the dropwise addition. After the reaction was completed, it was directly suction-filtered, and the filter cake was washed with water until the aqueous solution was neutral, then washed 3 times with acetone until the acetone was colorless, and vacuumed (vacuum degree: 0.1) Drying at 45° C. for 24 hours to obtain dry polyaniline doped with styrenesulfonic acid.

[0027] Preparation of Copolymer Materials with High Dielectric Constant

Embodiment 2

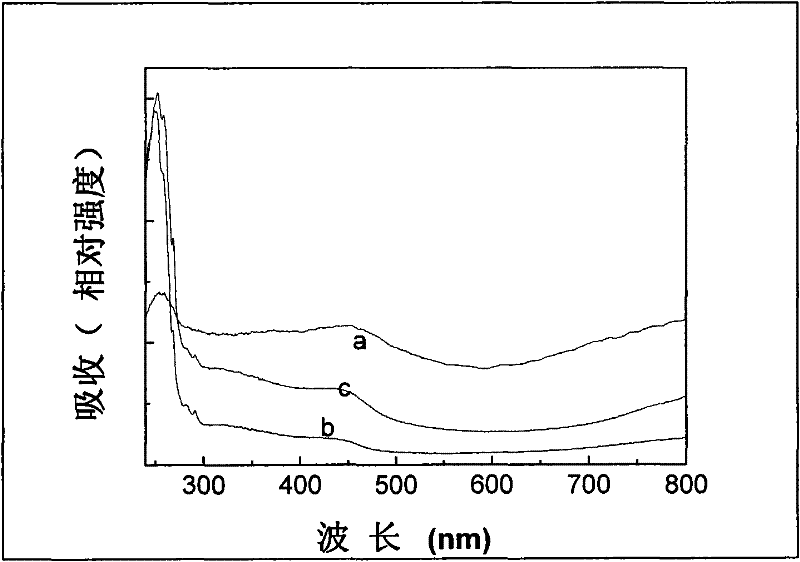

[0029] The polyaniline doped with styrenesulfonic acid and styrene according to the total mass fraction of polyaniline doped with styrenesulfonic acid are 0, 5%, 7%, 10%, 15%, 20%, 25%, 30% %, 35%, and 38% to carry out the polymerization reaction to obtain a series of all-organic high-dielectric copolymers whose side chains contain polyaniline segments.

[0030] Taking as an example when the mass fraction of polyaniline doped with styrene sulfonic acid is 20%, the obtained copolymer is defined as copolymer-20, and so on. The polymerization reaction is: 2.083g of polyaniline doped with styrenesulfonic acid and 0.5208g of styrene monomer are added to a 50mL three-neck flask, then 2mL of toluene solvent is added, and 0.0492g of azobisisobutylene is added after ultrasonication for 30min. Nitrile, deoxygenated with argon for 30 minutes, reacted in an oil bath at 85°C for about 6 hours, and removed the solvent to obtain an all-organic high-dielectric copolymer with polyaniline segme...

Embodiment 3

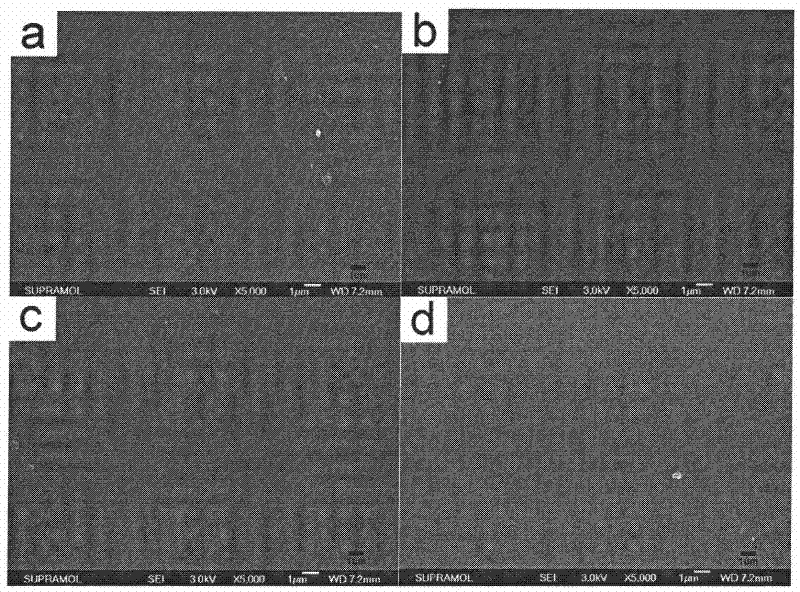

[0033] Dissolve the obtained all-organic high-dielectric copolymer containing polyaniline segment in the side chain in tetrahydrofuran to configure a solution with a mass fraction of the copolymer of 10%. After the copolymer is completely dissolved, pour the solution of the copolymer into the On a clean and horizontal conductive glass plate, dry at room temperature for 48 hours, and then dry at 45°C for 12 hours to obtain a copolymer film. The scanning electron microscope photos of the surface of the copolymer film are as follows: image 3 shown.

[0034] Testing of High Dielectric Materials

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com