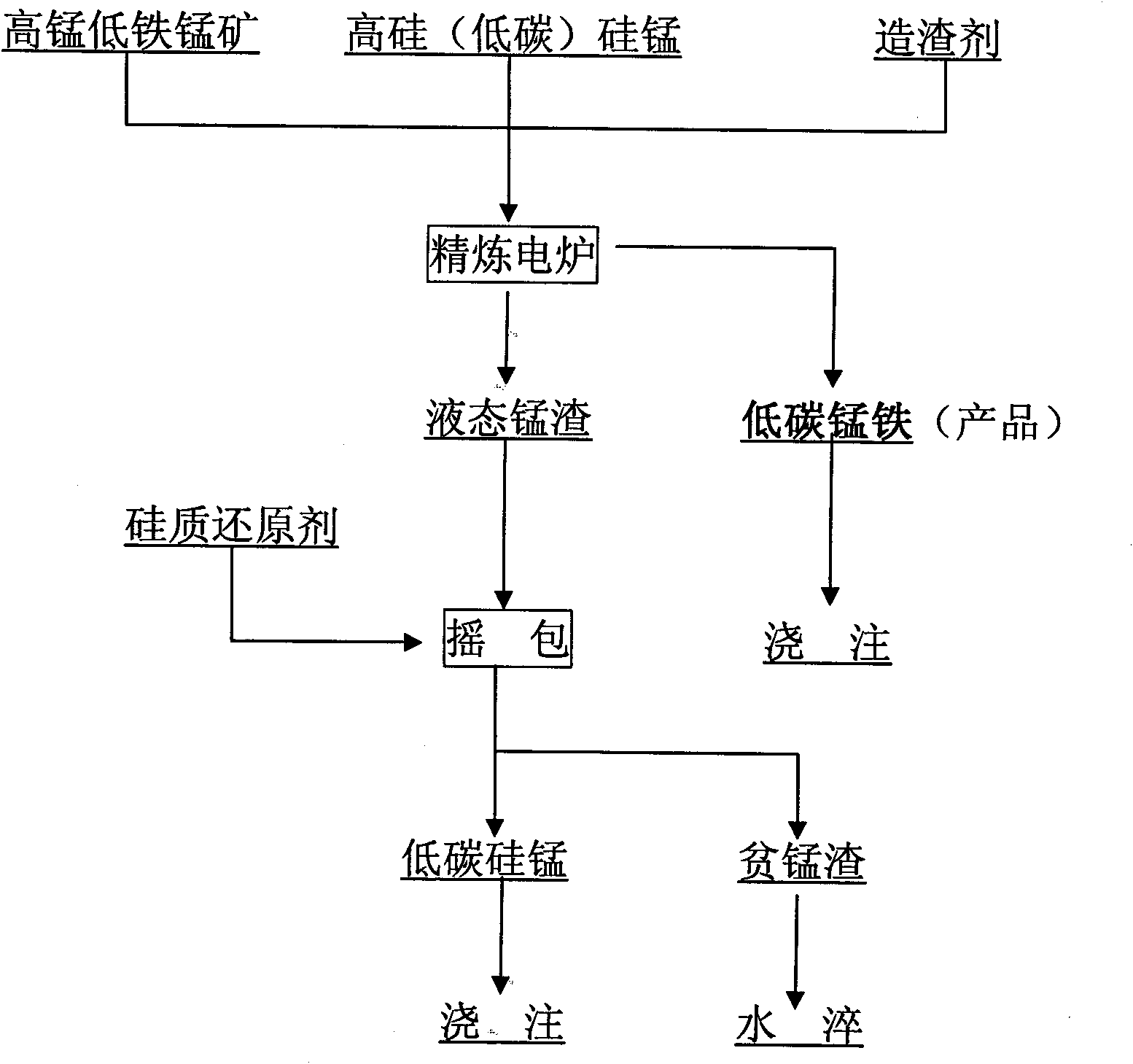

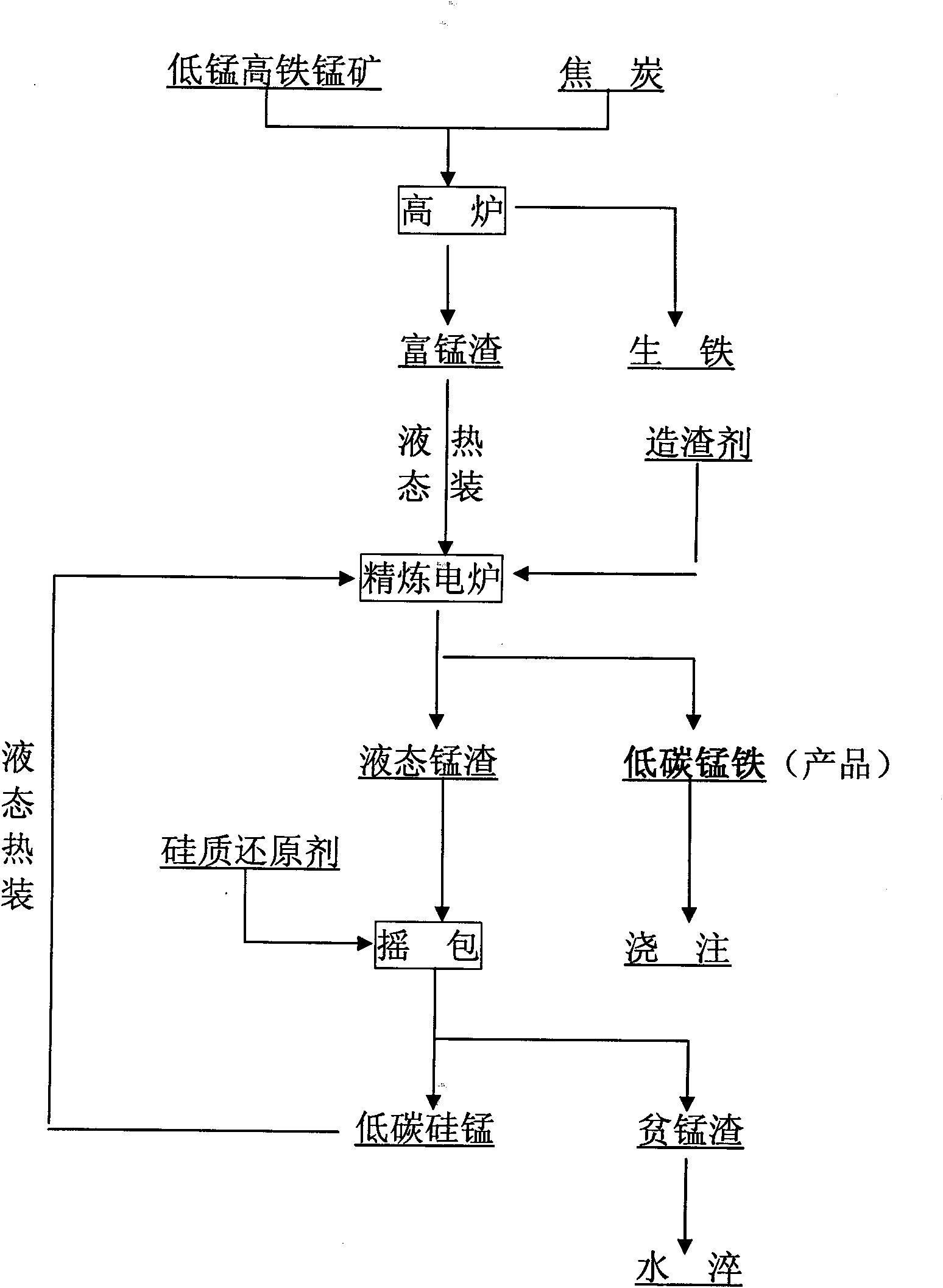

Production method of low-carbon ferromanganese

A low-carbon ferromanganese and production method technology, applied in the field of metallurgical engineering, can solve problems such as high product production cost, high product comprehensive energy consumption, and shortage of raw material resources, so as to improve product quality, make full and efficient use, and save product production consumption. The effect of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] 1. Blast furnace smelting to produce liquid manganese-rich slag: use two kinds of low-manganese and high-iron imported manganese ore and coke according to the following ratio to mix and prepare, and then enter the blast furnace for smelting:

[0040] Raw material type Imported manganese ore 1 Imported manganese ore 2 Coke

[0041] Dry weight of each batch (Kg) 450 450 250

[0042] The quality of manganese ore (by weight) is as follows:

[0043] Manganese ore chemical composition Mn Fe Mn+Fe P SiO2 Al2O3

[0044] Imported manganese ore1 weight ratio (%) 25 31 56 0.04 3.0 4.5

[0045] Imported manganese ore 2 weight ratio (%) 25 29 54 0.06 3.0 5.5

[0046] Mixed manganese ore weight ratio (%) 25 30 55 0.05 3.0 5.0

[0047] Coke quality (by weight) is as follows:

[0048] Fixed C 84% Ash content 13% (Ash contains SiO2 40%, Al2O3 25%, P 0.3%)

[0049] The chemical composition (by weight) of the manganese-rich slag produced by blast furnace smelting is as follows:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com