Method for improving strength of polyphenylene terephthalamide fibers through heat setting

A technology of poly-p-phenylene terephthalamide and p-phenylene phthalamide, which is applied in the direction of dry cleaning fiber products, textiles and paper making, liquid/gas/vapor removal with squeeze rollers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

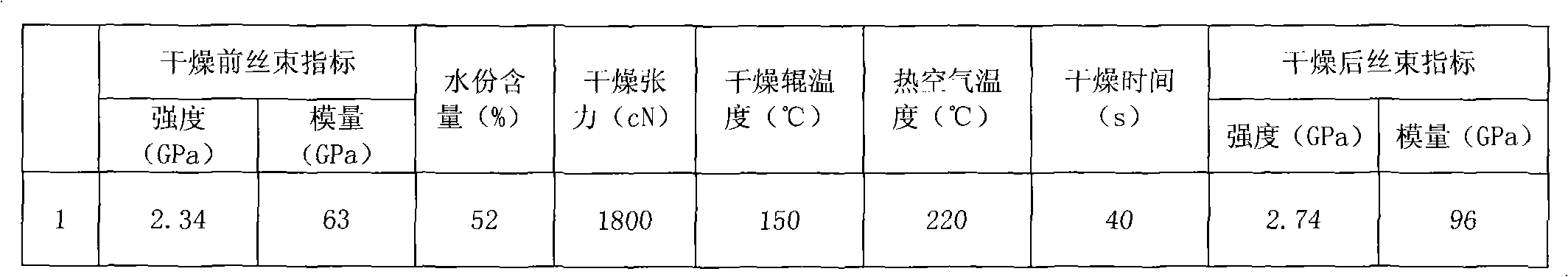

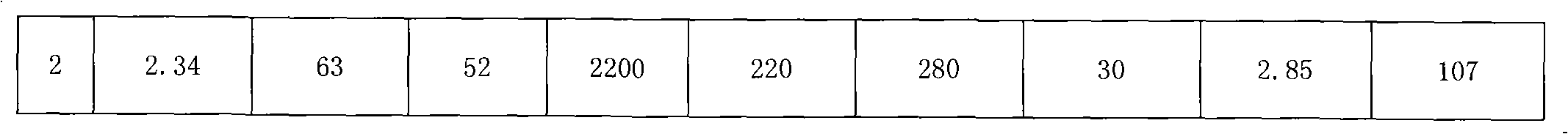

Embodiment 1

[0013] The method for improving poly-p-phenylene terephthalamide fiber strength by heat setting of the present invention comprises the steps:

[0014] (A) Poly-p-phenylene terephthalamide fiber tow is washed, and then the poly-p-phenylene terephthalamide fiber tow is squeezed and dehydrated by a water squeezing device. The percentage by weight of moisture in the terephthalamide fiber tow is controlled at 40% or 45% or 48% or 50% or 52% or 55% or 60%, or between 40% and 60% other values;

[0015] (B) The poly-p-phenylene terephthalamide fiber tow obtained in step (A) is dried, stretched and drawn by a drying roll, and the temperature of the drying roll is 150°C or 160°C or 180°C or 200°C or 210°C or 220°C or 240°C or 260°C or 270°C or 280°C or 300°C, the temperature of the drying roller can also be other values between 150 and 300°C, and let the polyparaphenylene terephthalamide The fiber tow passes through the drying oven in the state of being stretched and drawn. The tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com