Surface pasting type vibration wire type reinforcing steel strain gauge

A strain gauge and vibrating wire technology, which is applied in the field of civil engineering testing instruments, can solve the problems of complex installation, lower measurement accuracy, and errors, and achieve the effects of simple structure, convenient use, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

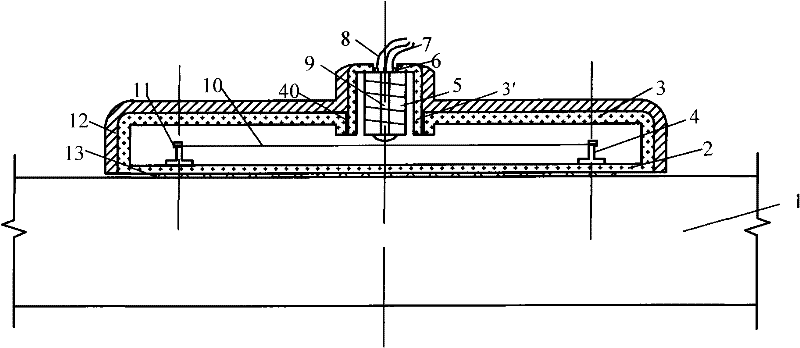

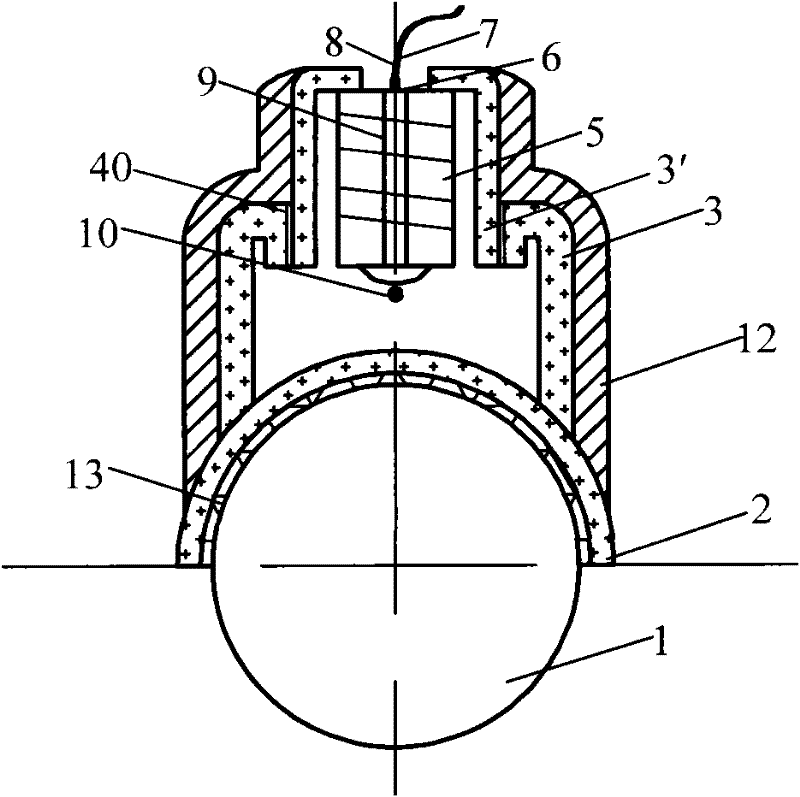

[0028] Further illustrate the present invention below in conjunction with accompanying drawing:

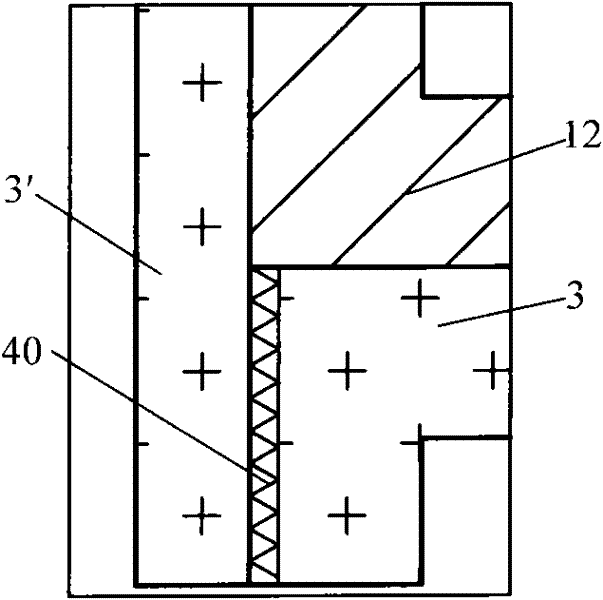

[0029] Such as figure 1 , figure 2 As shown, the present invention is a surface-attached type vibrating wire strain gauge, which comprises an upper chamber 3', a lower chamber 3, a signal pick-up device and a signal transmission system;

[0030] Wherein, the signal pick-up device is made of metal patch 2, vibrating wire support 4, vibrating wire 10 and vibrating wire clamping device 11; fixed on the central axis position of the upper surface of the metal patch 2 along the length direction, the metal patch 2 is affixed to the bottom of the lower chamber 3; the lower surface of the metal patch 2 is pasted with the steel bar 1 by an adhesive 13;

[0031] The signal transmission system includes a coil 5, a wire connector 6, a current wire 7 and a coil core 9; the coil 5 and the coil core 9 are fixed on the upper chamber 3', and the wire connector 6 is installed on the top of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com