Encapsulation structure of microwave isolator

A packaging structure and isolator technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems that cannot be disassembled and reassembled or repaired, it is difficult to provide magnetic paths, and increase the cost of machining, so as to achieve simple assembly and debugging Easy operation, excellent performance and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

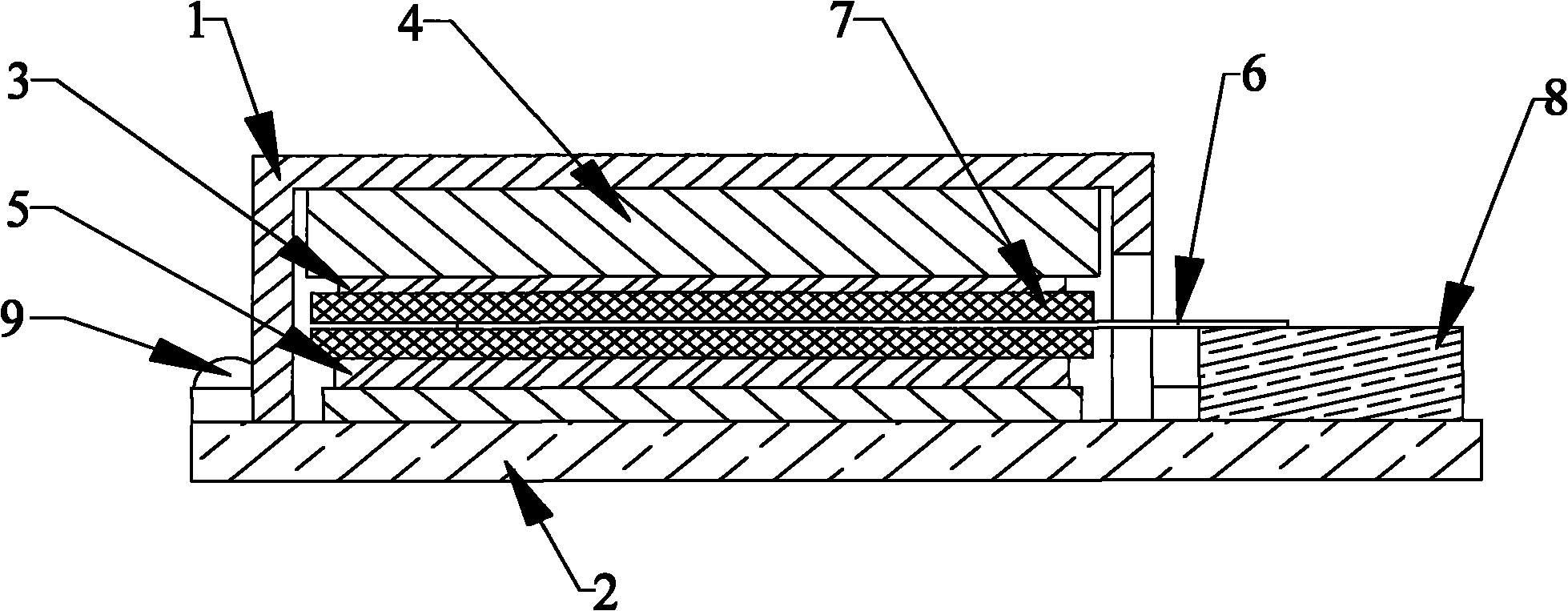

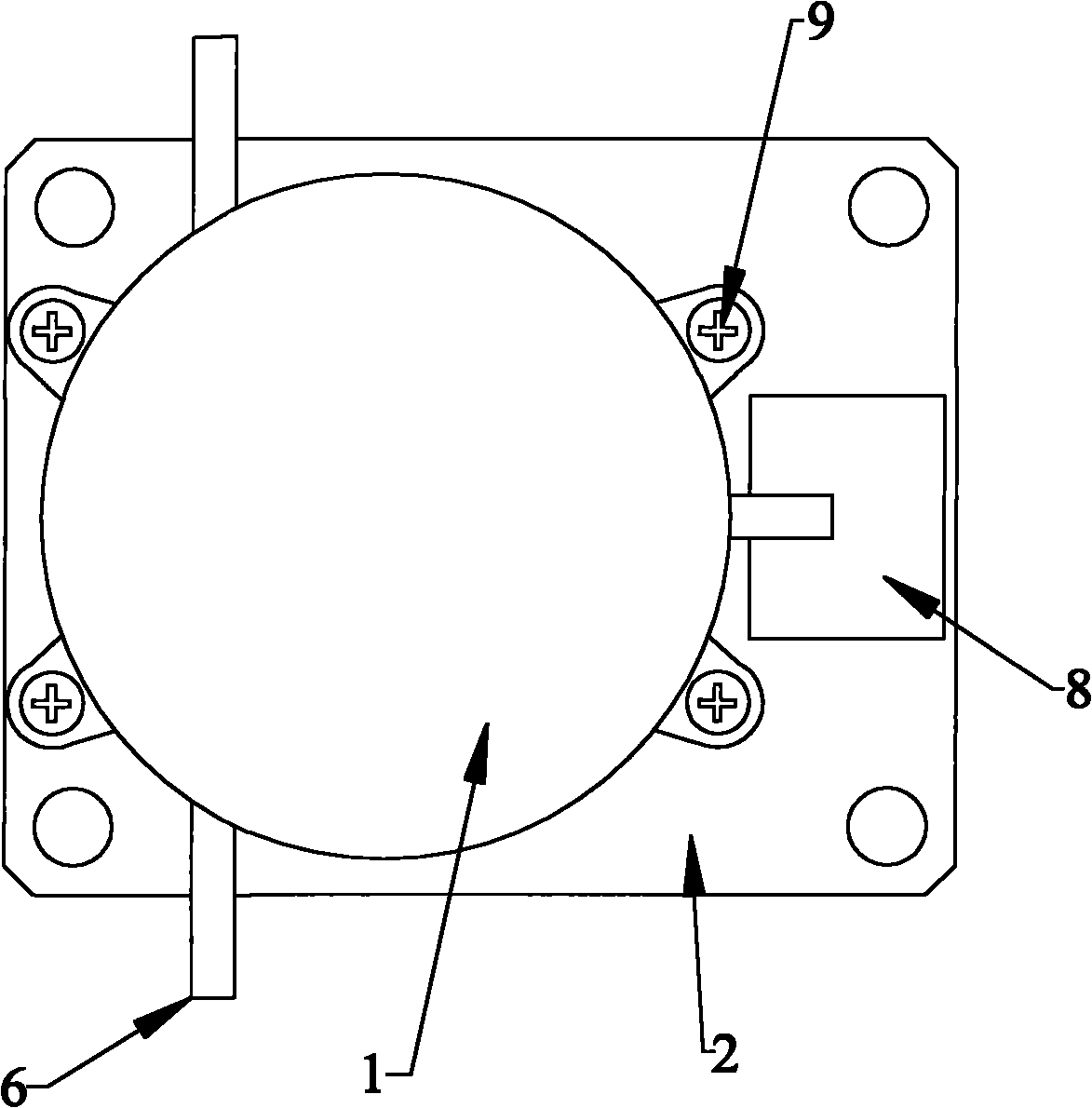

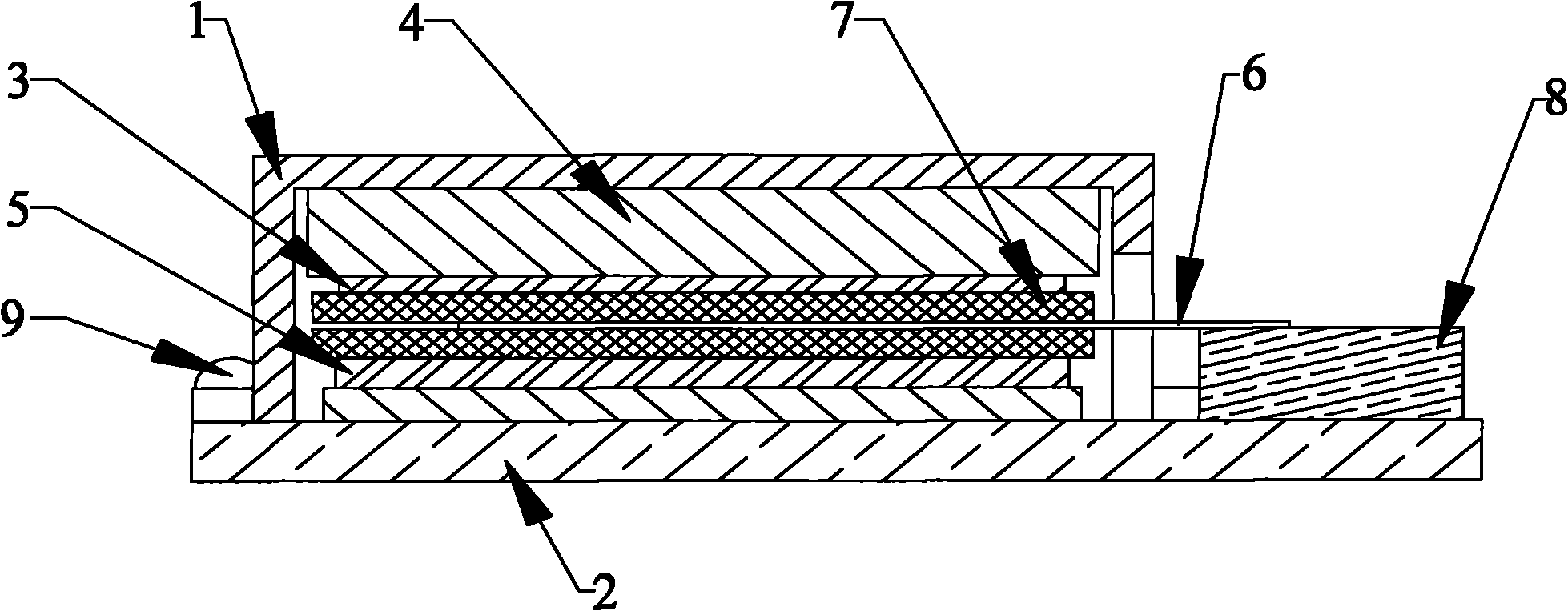

[0016] Such as figure 1 , figure 2 As shown, the packaging structure of the microwave isolator mainly includes a housing 1, a bottom plate 2) a homogeneous conductive sheet 5, a central conductor 6, a microwave ferrite 7, a temperature compensation sheet 3 and a permanent magnet 4, and the housing 1 has a side wall and the bottom surface, and form a cylindrical cavity with outwardly protruding flanges on the side walls; the bottom plate 2 is a plane structure, and a uniform magnetic conductive sheet 5, a central conductor 6, a microwave ferrite 7, and a temperature are placed on the bottom plate 2. The compensation piece 3 and the permanent magnet 4, the housing 1 is buckled upside down on the bottom plate 2, the uniform magnetic conductive piece 5, the central conductor 6, the microwave ferrite 7, the temperature compensation piece 3 and the permanent magnet 4 are accommodated in the cylindrical shape of the housing 1 In the cavity, and the central conductor 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com