Backflush device for a filter system

A filter system and filter body technology, which is applied in the direction of filtration separation, fixed filter element filter, transportation and packaging, etc., can solve the problems of increasing the flow resistance of the filter body, and achieve the effect of performance improvement and uniform backwashing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

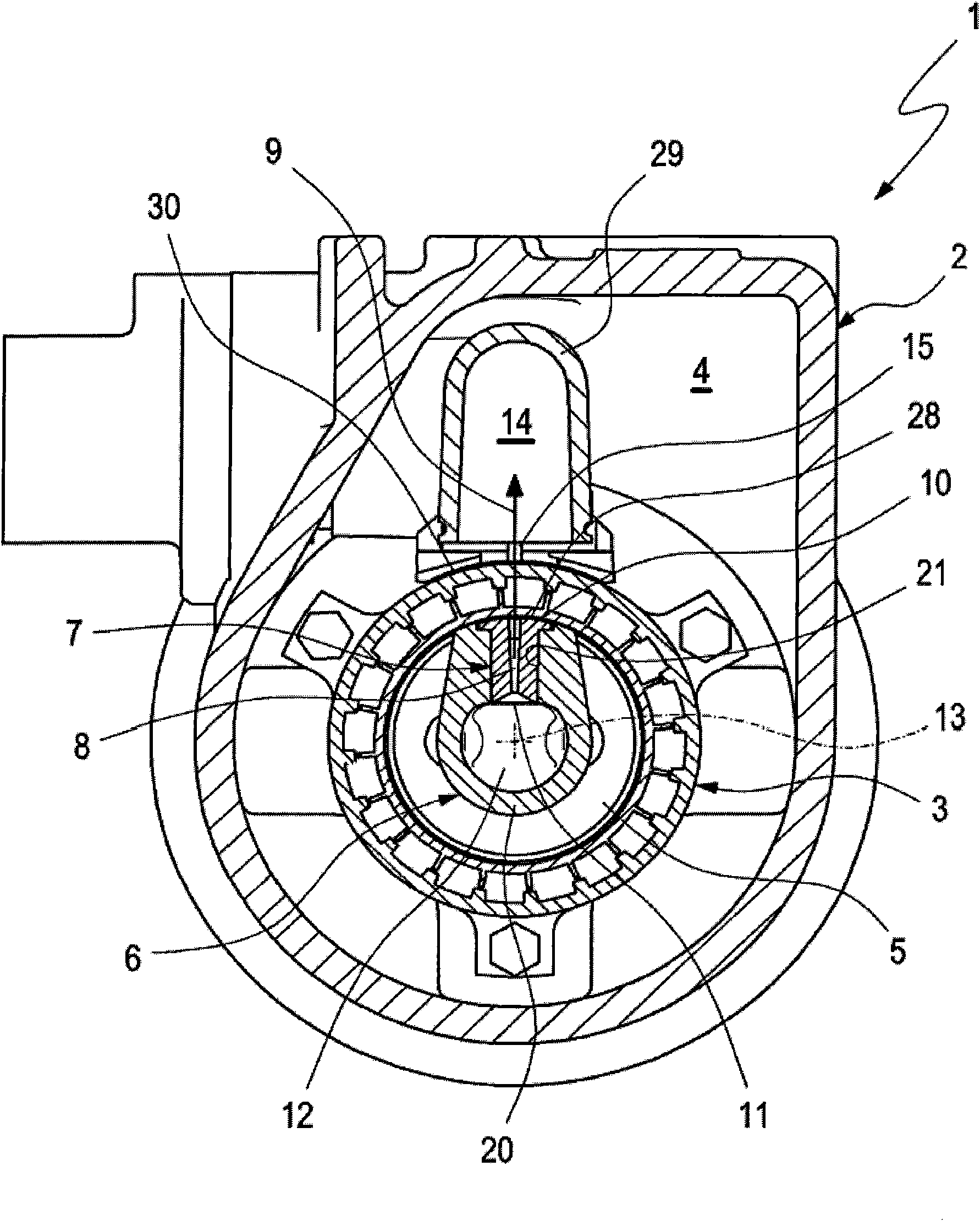

[0018] according to figure 1 , the filter system 1 has a housing 2 in which a filter body 3 is accommodated. In the housing 2 , the filter body 3 separates the inlet space 4 or the inlet side 4 from the clean space 5 or the clean side 5 . The filter body 3 has a cylindrical configuration and is preferably constructed in such a way that it is flowed through radially from the outside to the inside during filtration operation. As a result, the inlet space 4 is located radially outside the filter body 3 , whereas the clean space 5 is surrounded by the filter body 3 . The filter body 3 can be, for example, a known edge split filter. Basically, any other desired design for the filter body 3 is also conceivable, such as a filter body composed of micro-mesh material or pleated material. The filter system 1 is used to remove impurities from the liquid. In particular, solid particles can be filtered from the liquid. In principle, it can also filter out solid or liquid particles fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com