Wind driven electric power generator

A technology for a wind power generation device and a bearing part, which is applied to wind turbine components, wind energy power generation, wind turbines, etc., can solve problems such as damage to rolling elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

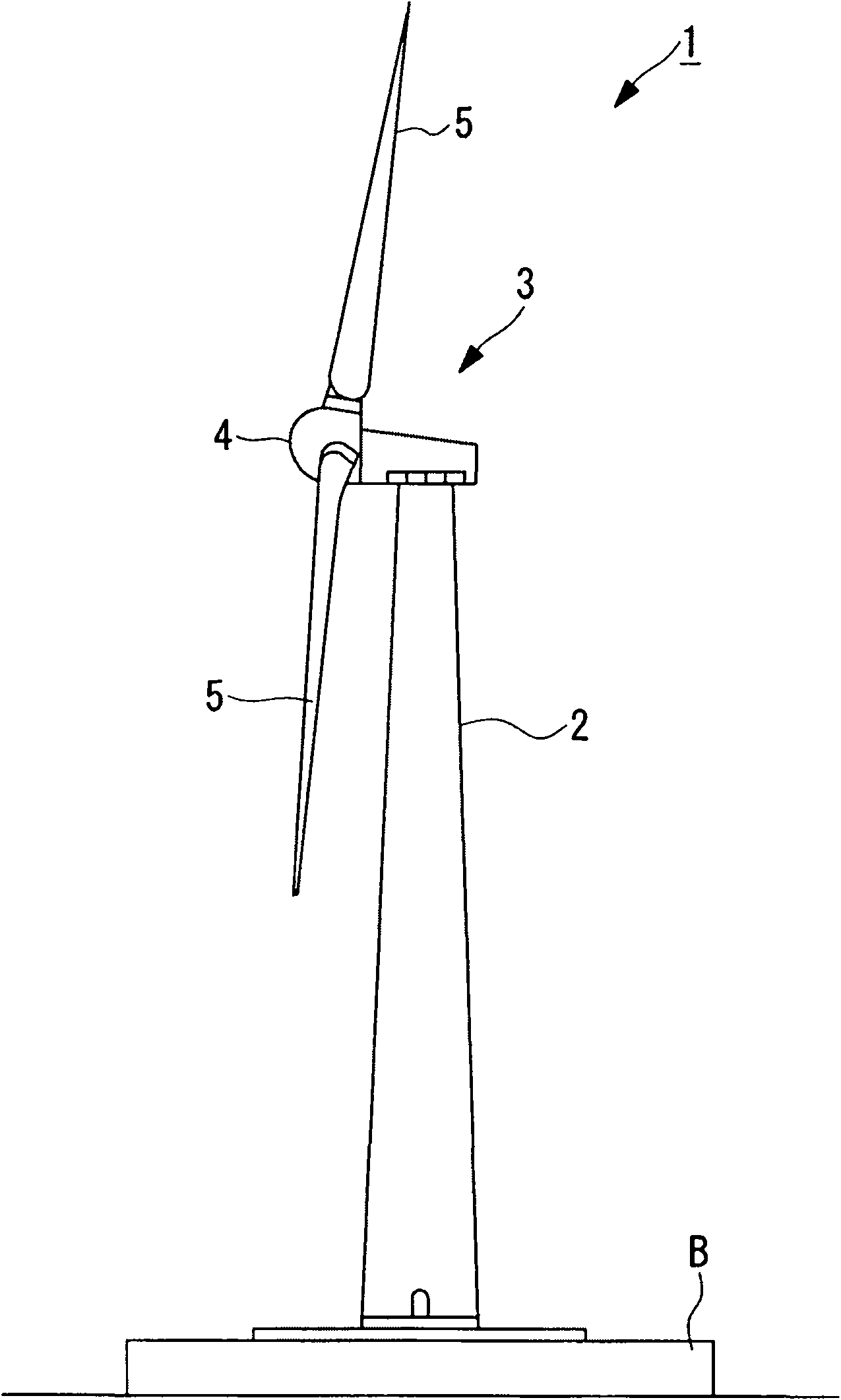

[0030] Below, refer to Figure 1 to Figure 4 One embodiment of the wind power generator of the present invention will be described.

[0031] exist image 3 The wind power generation device 1 shown in has: a pillar (also referred to as a "tower") 2 erected on a foundation B, a nacelle 3 arranged on the upper end of the pillar 2, and supported in a rotatable manner around a substantially horizontal transverse rotation axis. And be located at the rotor head 4 of the nacelle 3.

[0032] Around the rotation axis of the rotor head 4, a plurality of (for example, three) windmill rotor blades 5 are mounted radially. As a result, the force of the wind blowing toward the wind turbine rotor blades 5 from the direction of the rotation axis of the rotor head 4 is converted into power for rotating the rotor head 4 around the rotation axis.

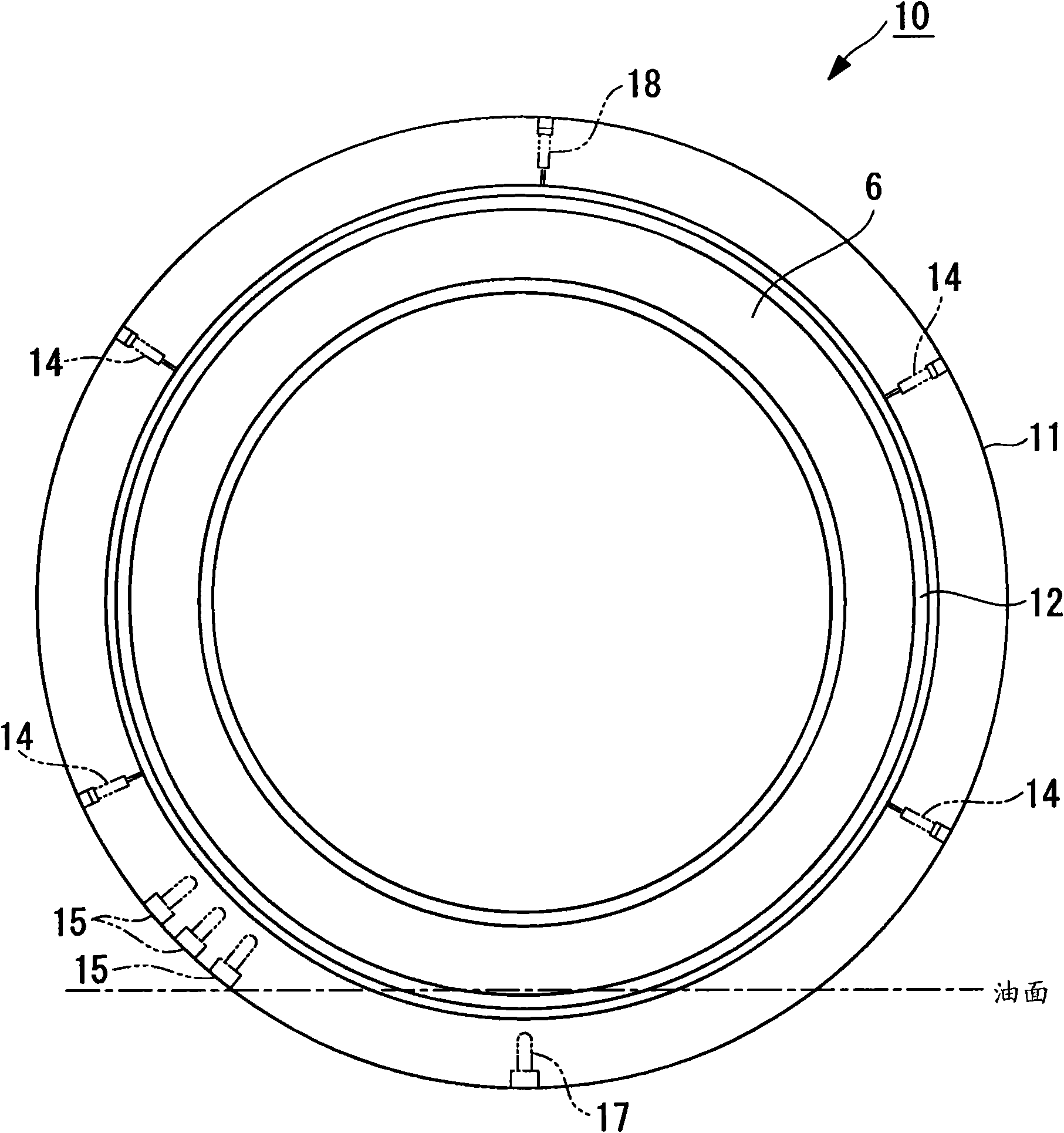

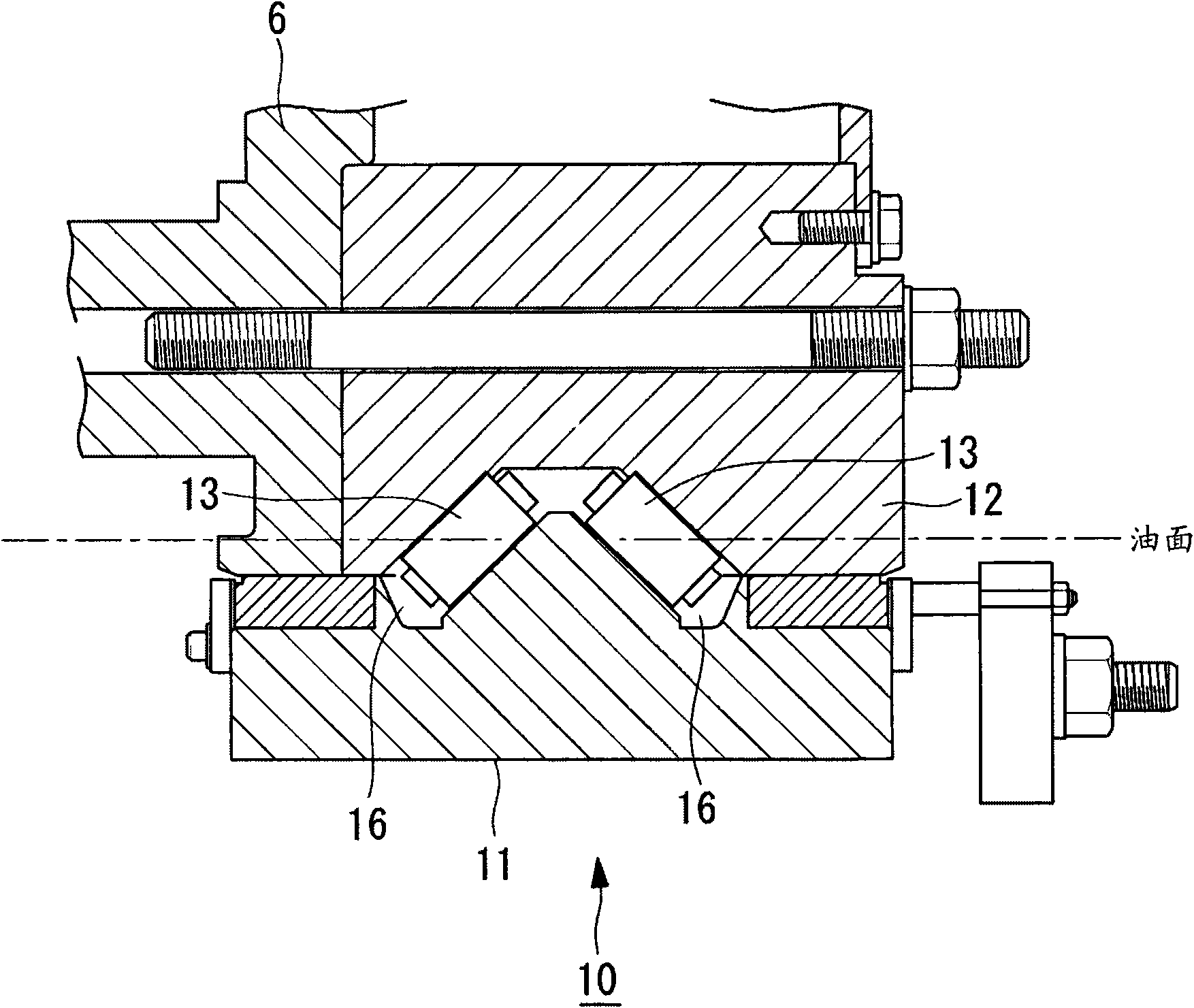

[0033] The above-mentioned wind power generator 1 has a main bearing portion 10 that supports a main shaft 6 arranged substantially horizontally. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com