Method and device for ventilation in primary tobacco baking in bulk curing barn

A technology of dense curing room and ventilation method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of increased energy consumption, reduced quality of tobacco leaf curing, and prolonged curing time, so as to reduce energy consumption and improve tobacco leaf curing. Quality, reduce the effect of temperature and humidity distribution unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

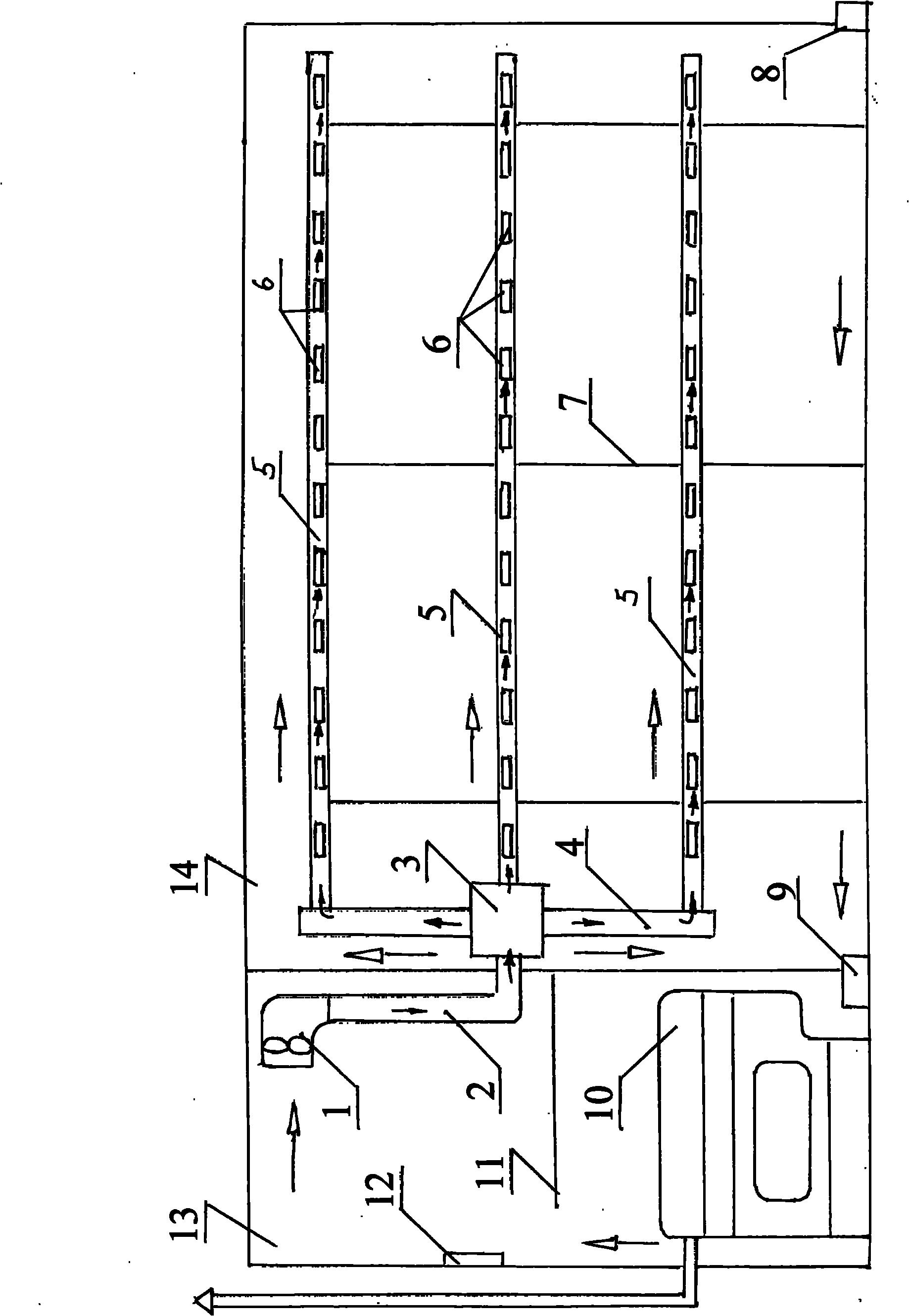

[0016] The present invention is further described in conjunction with the accompanying drawings and examples. See figure 1 , the air-supply ventilation device of the present invention is composed of a circulation fan 1, an air-supply main pipe 2, a static pressure box 3, an air-supply standpipe 4, a horizontal air-supply pipe 5, a diffuser 6, and an Pipe support 7, moisture discharge port 8, air return port 9, hot blast stove 10, baffle plate 11, supplementary air port 12 constitute. Taking three rows of tobacco leaves hanging in the smoke chamber as an example, three groups of horizontal air supply pipes 5 are arranged in the horizontal direction. Diffusers 6 are placed on both sides of the horizontal air supply pipe 5 . In order to fully carry out heat exchange between the air returning from the smoke chamber and the hot blast stove, a baffle plate 11 is set in the middle of the heating chamber 13 . The air supply port 12 is located on the outer wall of the heating chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com