Reversible hammer crusher

A hammer crusher and hammer technology, applied in the field of crushing equipment and reversible hammer crusher, can solve the problems of high manufacturing cost, low manufacturing cost, poor performance of hammer crusher, etc., and achieve crushing Good effect and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

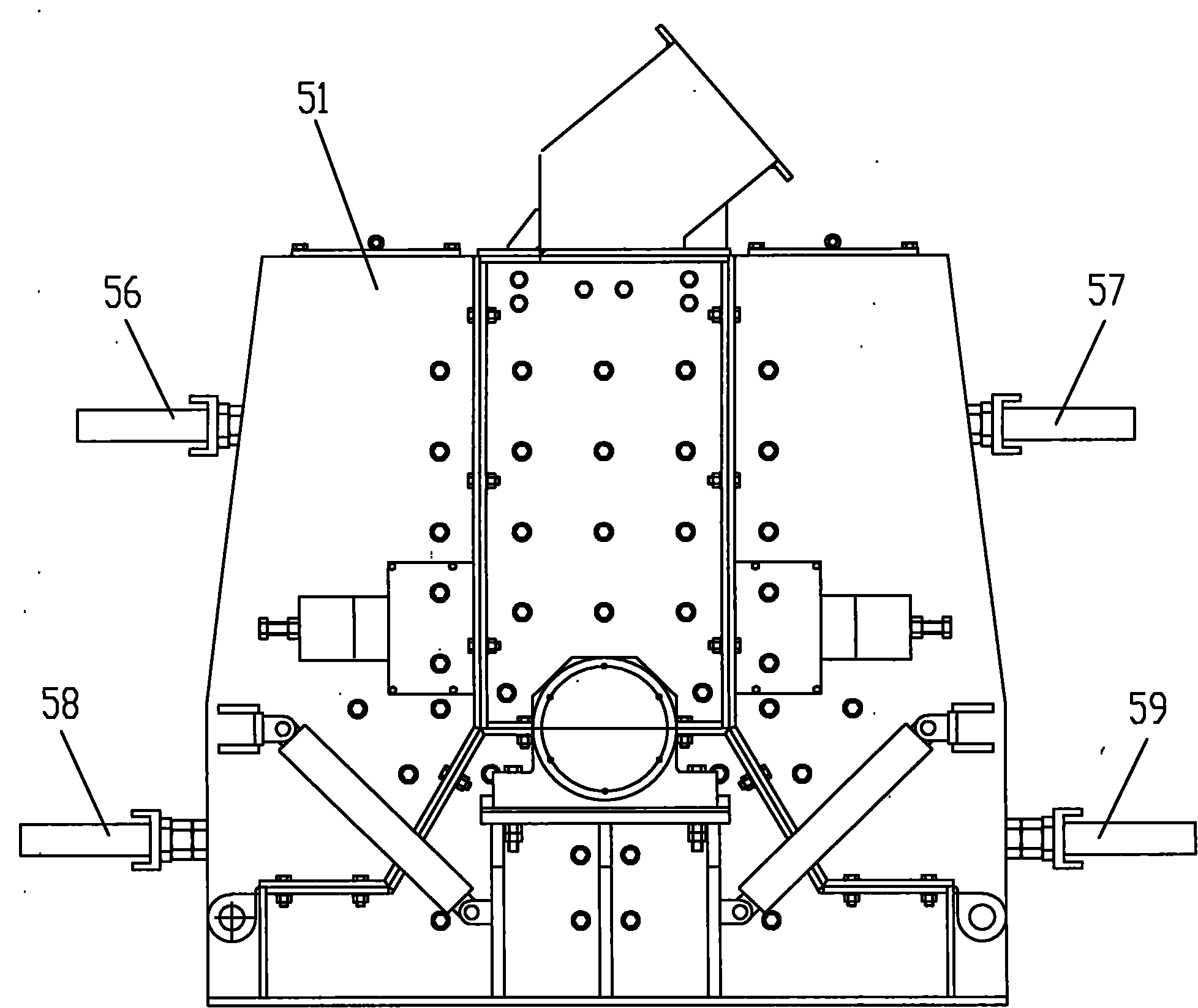

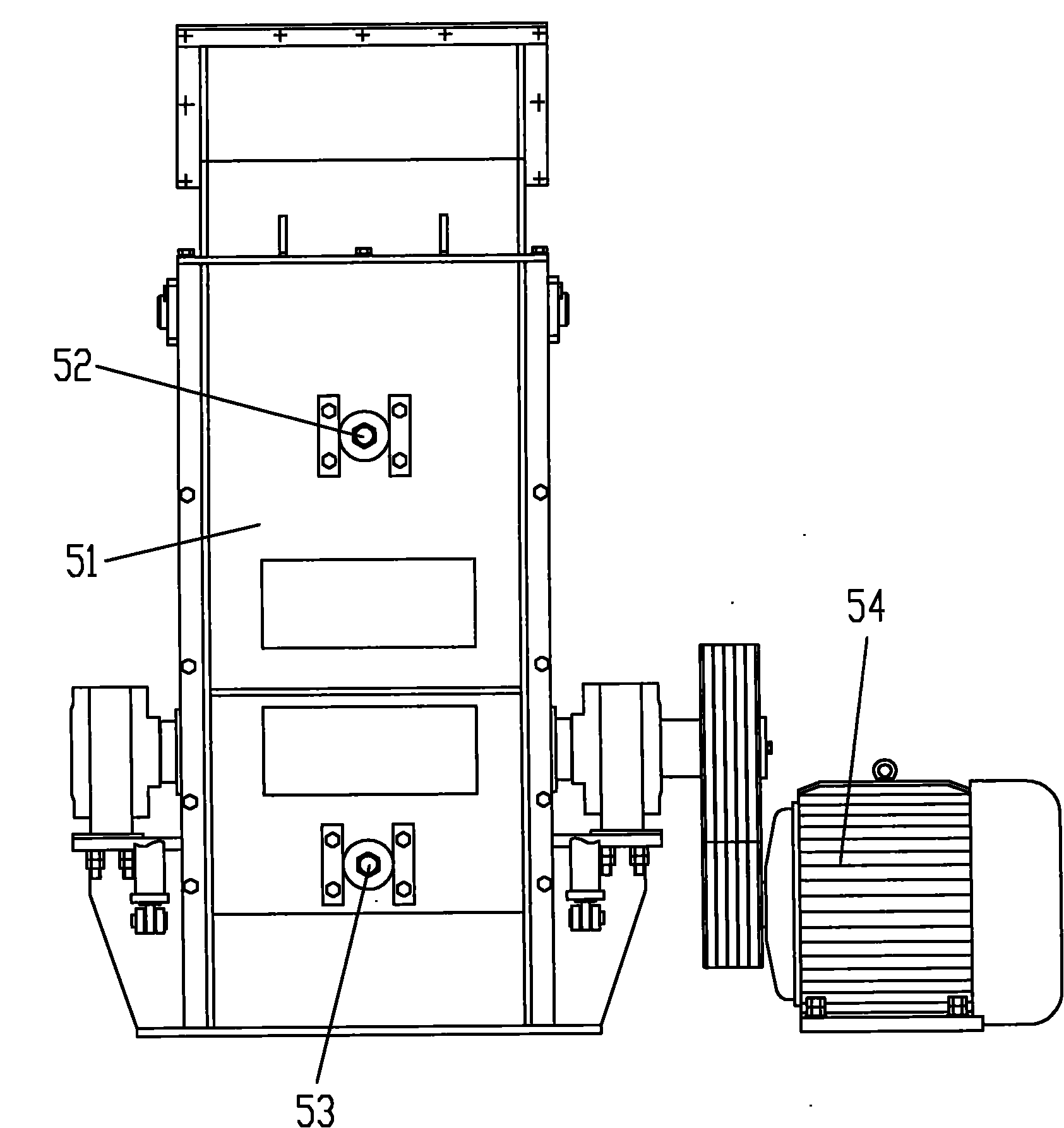

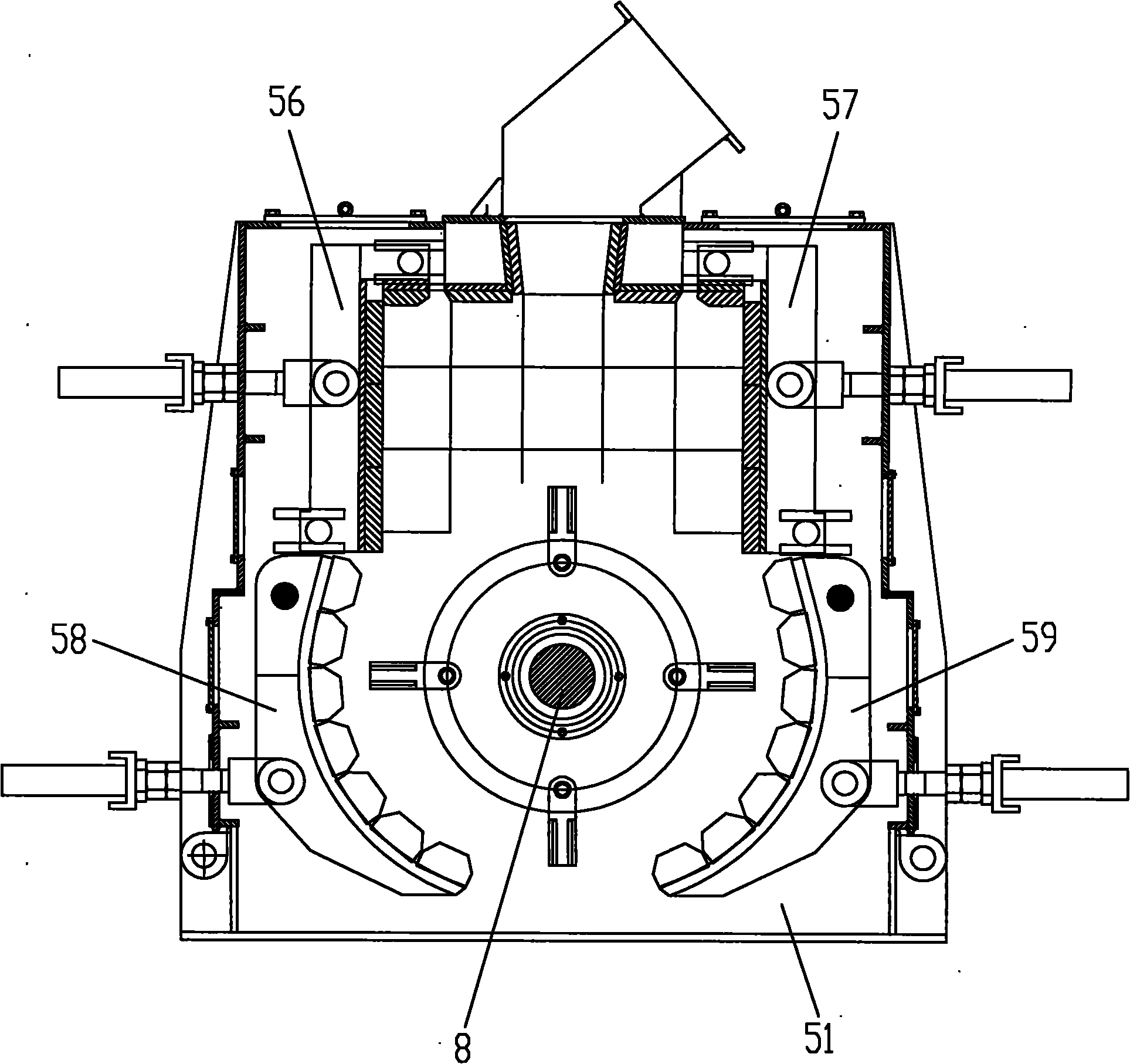

[0040] see Figure 1 to Figure 13 , the reversible hammer crusher in this embodiment includes a frame 51, an upper impact frame 52, a lower impact frame 53, a motor transmission 54 and a rotor 8, wherein the frame 51 has a crushing cavity, and the frame 51 A feeding inlet is also arranged on the top, and the structure of the frame 51 is common knowledge to those skilled in the art. The motor transmission transposition 54 in this embodiment includes a main shaft, a motor and a transmission belt. The main shaft and the motor are connected through a transmission belt, and the motor can drive the main shaft to rotate. Located in the crushing cavity of the frame 51.

[0041] The upper impact frame 52 in this embodiment is divided into an upper left impact frame 56 and an upper right impact frame 57. The upper left impact frame 56 and the upper right impact frame 57 have the same structure, and the upper left impact frame 56 and the upper right impact frame 57 They are all install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com