Clamp ring cleaning protection and measuring jigs

A compression ring and jig technology, which is applied in the direction of measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as prolonging the replacement cycle of customer parts, low efficiency of clamping surface height measurement, and increasing the frequency of cleaning of the compression ring. Measuring the effects of inefficiency, loss reduction, and maintenance cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

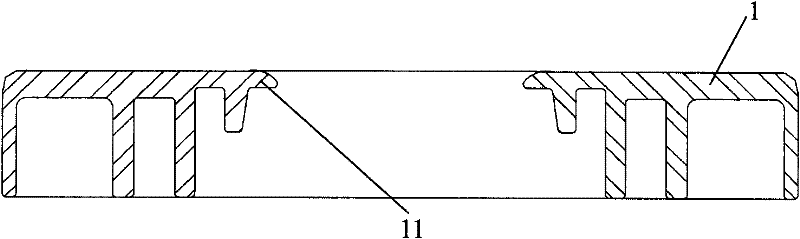

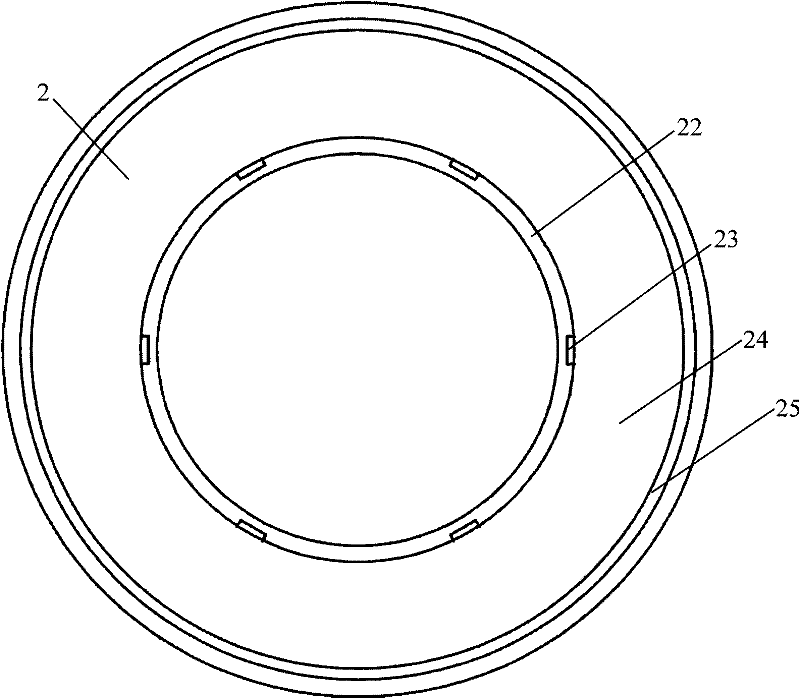

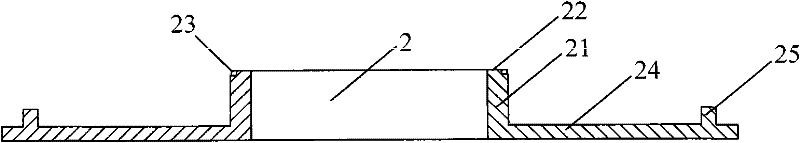

[0033] see figure 2 and image 3 shown, combined with figure 1 As shown, the clamping ring cleaning bottom protection jig 2 of the present invention includes a clamping surface support part 21 , and the clamping surface support part 21 has a top surface 22 supporting the bottom of the clamping surface 11 of the clamping ring 1 .

[0034] Preferably, the clamping surface support part 21 is a clamping surface support ring. More preferably, the top outer side of the sandwich support ring has at least one pair of inwardly symmetrical recesses 23 . In a specific embodiment of the present invention, there are three pairs of inwardly symmetrical depressions 23 on the top outer side of the sandwich support ring. Ensure that the 6 small pieces (pads) on the clamping surface 11 of the compression ring 1 fall in the 6 depressions 23, so that the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com