Method for producing nicergoline

A nicergoline, production method technology, applied in chemical instruments and methods, products, chemical/physics/physicochemical processes and other directions, can solve problems such as environmental pollution, synthetic reaction quality factors, etc., achieves simple operation, sealing The effect of good performance and environmental protection, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

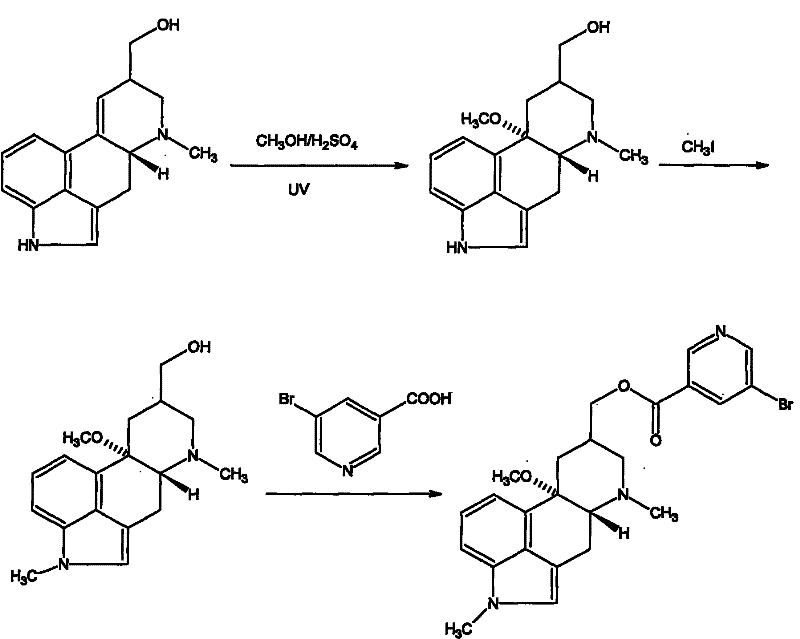

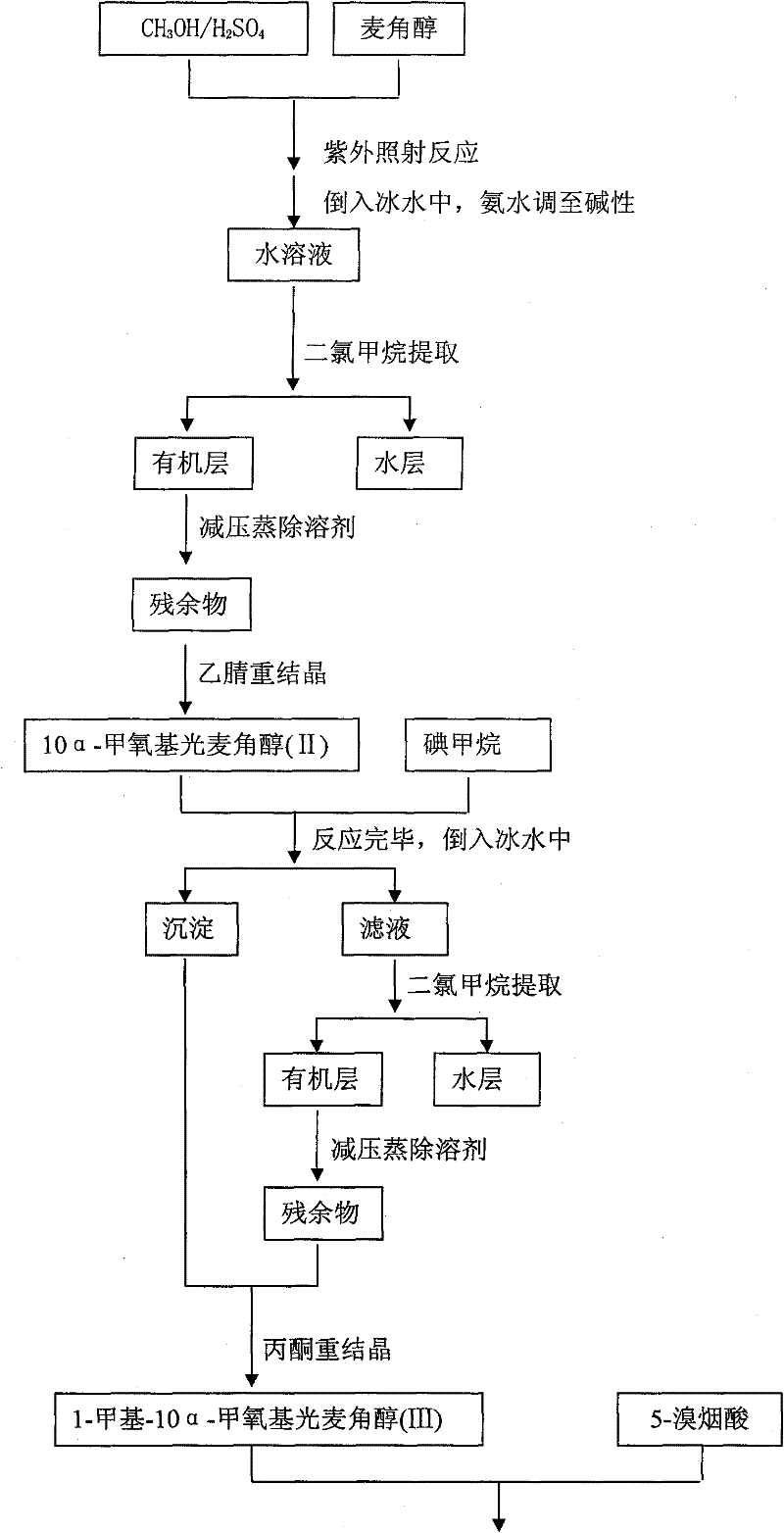

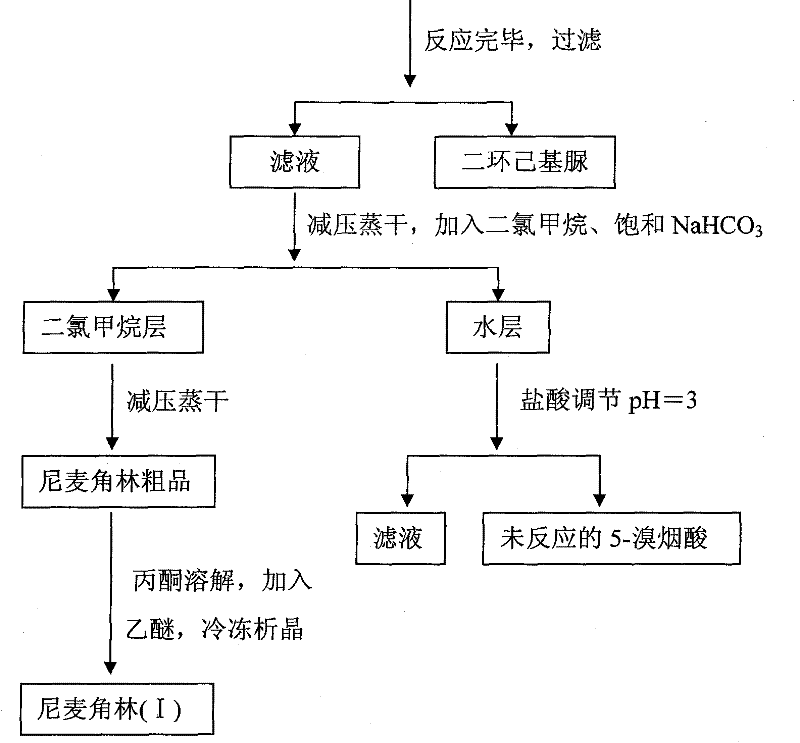

Method used

Image

Examples

Embodiment Construction

[0029] 1, Preparation of 10α-methoxy phoergool (II)

[0030] Under the protection of nitrogen, add 3.9LCH to the multifunctional reaction kettle with special bottom valve 3 OH / H 2 SO 4 (40 / 7.5) and ergot alcohol 130g, heated to dissolve (temperature control 35 ~ 40 ℃); ultraviolet irradiation reaction (Philips UV lamp of HPLR-N 250W, 330nm, 20 ~ 40 ℃), after the reaction, the reaction The solution was poured into about 15L of ice water, slowly added 1.7L of ammonia water, extracted with dichloromethane (4L×3), the organic layer was washed with water, and anhydrous Na 2 SO 4 After drying, the solvent was evaporated under reduced pressure, the residue was recrystallized with acetonitrile, and filtered with a special filter to obtain 102 g of product (II), with a yield of 70%.

[0031] Product quality control: Product (II) is a brown powder with a melting point of 183-187°C.

[0032] Reaction process monitoring: TLC method, silica gel GF254 plate, developer CH 3 OH: CHCl 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com